Difficulties from the first mushroom embryos

Late afternoon, the yellow light from the small mushroom workshop of Mrs. Sai Thi Sinh in Binh Chuong village, Dinh Lap commune still shines out onto the porch. The space is warm and fragrant with the scent of wood. The pure white mushroom spawn strings are hung in neat rows, layer upon layer of plump, round mushroom caps spreading out. Mrs. Sinh quickly picks each bunch of mushrooms, her hands are used to the job, her eyes are calm as if she has experienced all the hardships of the job.

Looking at the mushroom factory today, it is hard to believe that she failed right from the start. “Mushroom farming is very risky, nothing goes smoothly right away. You have to persevere to succeed, there is no easy path,” she recalls.

Ms. Sinh packs each bag of freshly picked oyster mushrooms - a familiar job that has been with her for many years in the profession. Photo: Hoang Nghia.

She started growing mushrooms in 2016, when no one in the commune was doing the job. The first batch of mushrooms suddenly turned white and moldy, spoiled by the humidity and lack of technique. She lost everything but was not discouraged, she told herself she had to go to school to learn.

“If no one taught me, I had to learn by myself,” she recalls the days she went to Bac Giang (old) to observe each stage of professional mushroom growers such as processing spawn, maintaining humidity, controlling light, detecting diseases, etc.

She brought back what she learned and applied it. From a few temporary sheds, she expanded and upgraded it into a 1,200m² mushroom farm with fixed, sealed rooms and temperature and humidity control based on experience accumulated over many years. Each batch, she maintained about 4,000 - 5,000 pots, at times up to 15,000 pots.

Thanks to the change in mindset, the mushroom model gradually stabilized. The mushroom spawns that once discouraged her have now become a stable source of income for the whole family.

"Miss Sinh" oyster mushroom reaches 3-star OCOP milestone

Every day, Ms. Sinh opens the workshop to check the humidity, adjusts the mist nozzles and observes how each mushroom spawn “breathes”. In the closed space, moisture clings to each spawn string hanging along both sides of the wall. She walks slowly through each row, observing carefully to ensure that the mushrooms grow evenly. The job is not as hard as farming, but it requires meticulousness in every step, especially when the weather changes suddenly.

Ms. Sinh said that the annual output is usually 7-10 tons, depending on the weather. White or brown oyster mushrooms are sold for 30,000-40,000 VND/kg, in favorable years, the family earns more than 200 million VND. In addition to the family's income, the mushroom factory also creates jobs for people around the area. "Sometimes I hire 4-5 people, at peak times, 10 people. It's just to help people earn extra income," she said.

When production stabilized, she completed the label, barcode and traceability records. Thanks to the support of local authorities and specialized sectors, in 2024, the oyster mushroom product “Miss Sinh” was recognized as a 3-star OCOP. This was a turning point for the family that had tried to figure it out on their own and failed in the first batch.

Persevere for a better tomorrow

Mr. Nguyen Chien Hiep - Chairman of Dinh Lap Commune People's Committee said that Ms. Sinh's mushroom growing model operates stably and effectively. This is the first household to grow mushrooms on a large scale in the locality, and the products are consumed both within the commune and in many outside markets.

The commune is planning to support the model to expand its scale, associated with product promotion and strengthening its brand in the market. “If the expanded household can produce, the commune will continue to support promotion and create conditions for the model to develop better,” said Mr. Hiep.

At Ms. Sinh's facility, mushroom bags are always checked regularly to ensure quality before being brought to market. Photo: Hoang Nghia.

For her part, Ms. Sinh is also planning to upgrade her facilities to expand production in the near future. The mushroom residue after harvest is processed into organic fertilizer, both saving costs and creating additional income.

In the middle of the white mushroom workshop, where rows of mushroom spawns hang like a garden growing in the humidity and yellow light, Mrs. Sinh slowly walks along each small path. Each of her steps seems to carry the weight of decades of accumulated experience, failures, batches of mushrooms spoiled by the weather, and nights spent staying up to adjust the humidity in time to save the batch of spawns.

Her journey, from the first failure, to the determination to learn a trade, to building each breeding room herself until the product achieved 3-star OCOP, is a testament to the perseverance of the people in the highlands. It is also the clearest answer that a small model, if built with passion, knowledge and perseverance, can still become an effective livelihood.

Source: https://nongnghiepmoitruong.vn/nam-so-len-doi-thanh-san-pham-ocop-d784096.html

![[Photo] General Secretary To Lam receives Governor of Kanagawa Province (Japan) Kuroiwa Yuji](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763204231089_a1-bnd-7718-5559-jpg.webp)

![[Photo] Exciting contest of skillful red fruit picking and creativity from Son La coffee beans](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763201832979_ndo_bl_3-jpg.webp)

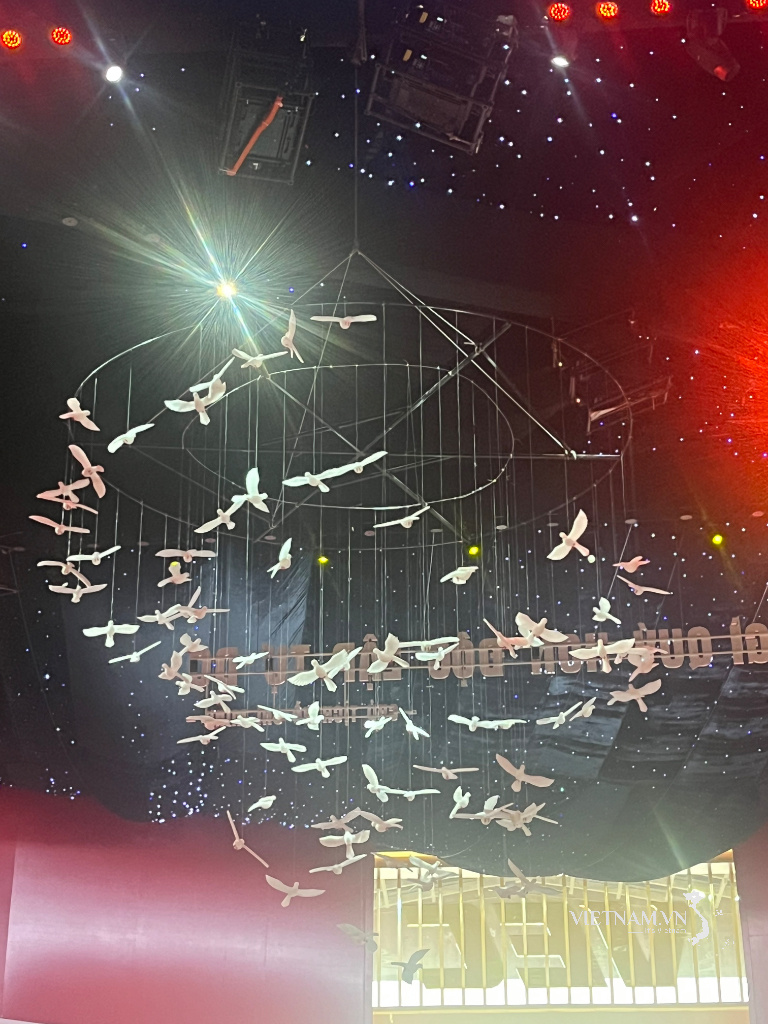

![[Photo] Panorama of the 2025 Community Action Awards Final Round](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763206932975_chi-7868-jpg.webp)

Comment (0)