Unmanned transformer station - A clear mark of digital transformation of 110kV power grid.

Digital transformation in the electricity industry does not stop at digitizing documents or modernizing equipment, but rather building a smart management and operation ecosystem, with many tools that are becoming increasingly essential such as: PMIS - A synchronous technical management system that helps monitor equipment status, track operations, incident history and maintenance; CBM - Maintenance method based on equipment status, instead of traditional periodic maintenance. CBM helps save costs, while maintaining equipment reliability at the highest level during times of strong load increase; AI (Artificial Intelligence) is applied in image recognition from cameras, UAVs, flycams... minimizing the risk of manual omission, especially in harsh weather conditions...

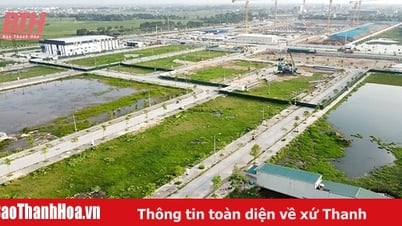

From software systems to grid sites, digital transformation is reshaping the way operations are performed. The 110kV unmanned substation is one of the most concrete examples. Without the need for on-site operators, the substation is completely remotely monitored via SCADA, with full data on current, voltage, fault warnings, equipment status, etc. At the same time, the coordination of operation - troubleshooting - maintenance is performed more accurately and flexibly than ever before.

Obvious benefits during the hot season: Reduce personnel pressure at the scene; respond quickly when load abnormalities occur; increase the ability to maintain continuous power supply, especially in key areas such as cities, hospitals, industrial parks; load forecasting, maintenance planning - especially important during peak season...

Digital transformer station – Long term goal, sustainable value.

Digital substation is the next step, in which the digitization of data transmission in substations is considered a breakthrough in the field of substation automation. Previously, the connection of data from substation equipment to IEDs in the operator's house was done by copper cables. With a large number of copper cables, it caused many difficulties in all tasks: from design, construction, testing and operation management. In particular, the secondary copper cable system accounts for a large proportion of the causes of incidents in substations.

Process Bus technology offers a digital data connection solution, implemented with just a few optical fibers, completely replacing the secondary copper cable system. It not only solves the existing difficulties caused by the copper cable system, but also creates opportunities to use advanced technology for the electricity industry to simultaneously solve many other difficult problems.

The whole country in general and the North in particular are entering the hot season, at this time the national power system is entering the most "stressful" period of the year. But instead of just increasing resources as before, the electricity industry is taking a more efficient and sustainable path, which is Digital Transformation. The 110kV grid - the connecting axis between transmission and distribution - not only plays an intermediary role, but is truly becoming the digital heart of the entire system.

Electricity industry officers and employees master technology, improve operational efficiency.

Everyone in the electricity industry is ready to change, master technology together, support each other on the digitalization journey, ensuring a common goal of helping the national power grid operate in a more modern and safe way and best serve all economic and social development needs, contributing to maintaining national defense - security and people's lives.

Dang Quynh (PC Thanh Hoa)

Source: https://baothanhhoa.vn/chuyen-doi-so-luoi-dien-110kv-buoc-tien-quan-trong-de-nang-cao-nang-luc-van-hanh-248461.htm

![[Photo] Prime Minister Pham Minh Chinh works with the Standing Committee of Thai Binh Provincial Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/f514ab990c544e05a446f77bba59c7d1)

![[Photo] Prime Minister Pham Minh Chinh starts construction of vital highway through Thai Binh and Nam Dinh](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/52d98584ccea4c8dbf7c7f7484433af5)

![[Photo] Buddha's Birthday 2025: Honoring the message of love, wisdom, and tolerance](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/8cd2a70beb264374b41fc5d36add6c3d)

Comment (0)