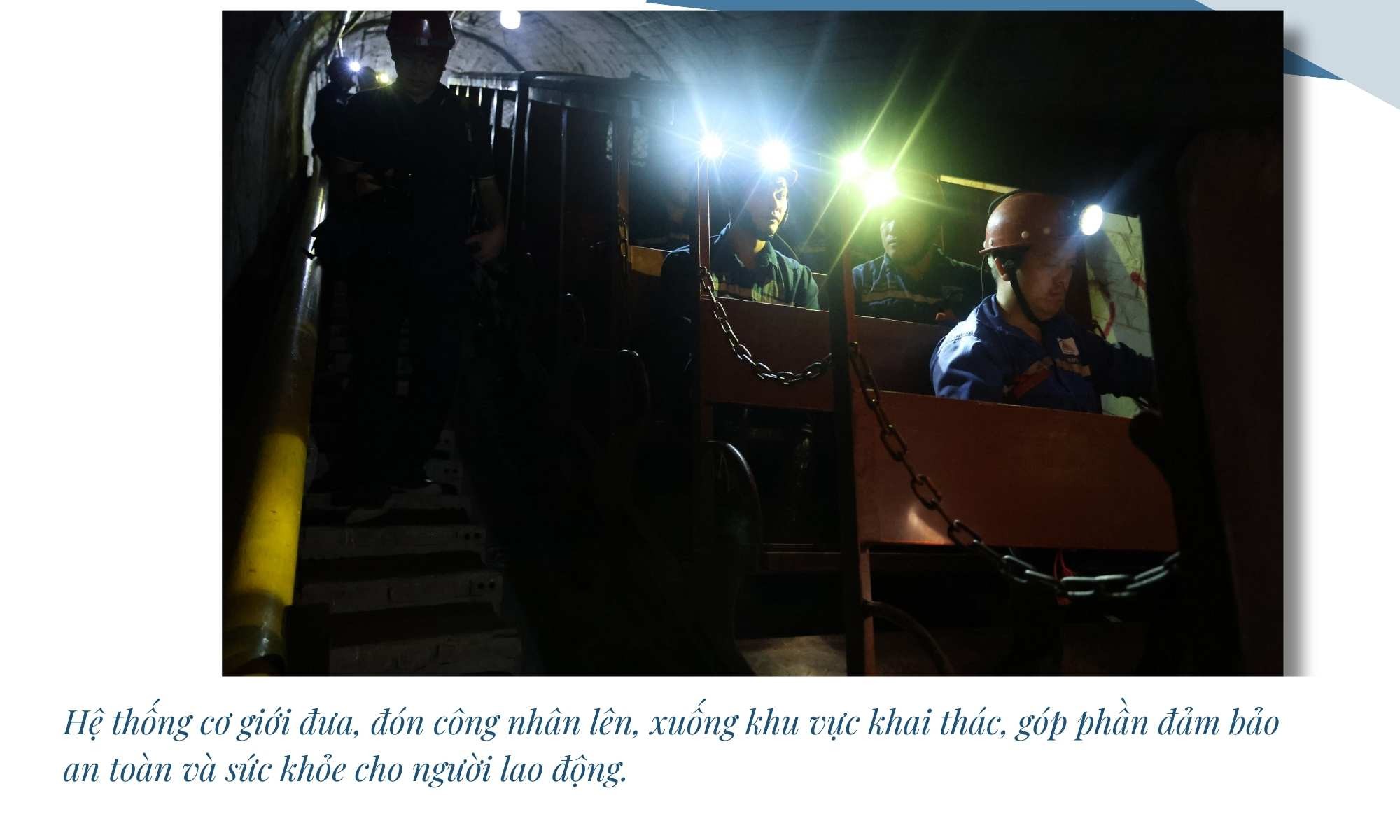

Previously, to get to the mining area deep underground, workers had to walk nearly half a kilometer. Recently, the workshop has invested in a mechanical system to transport workers up and down the mining area, contributing to ensuring the safety and health of workers.

Mr. Mac Van Tien, Manager of the Underground Workshop, said: Workers moving into the mining area must go through a secondary shaft, about 480 m long in total, with a slope of 23 degrees. Before there was no mechanical system, workers had to walk very tired, especially after working shifts.

The underground workshop has nearly 400 workers, divided into 3 shifts, each lasting 8 hours. Underground mining is much more difficult than open-pit mining.

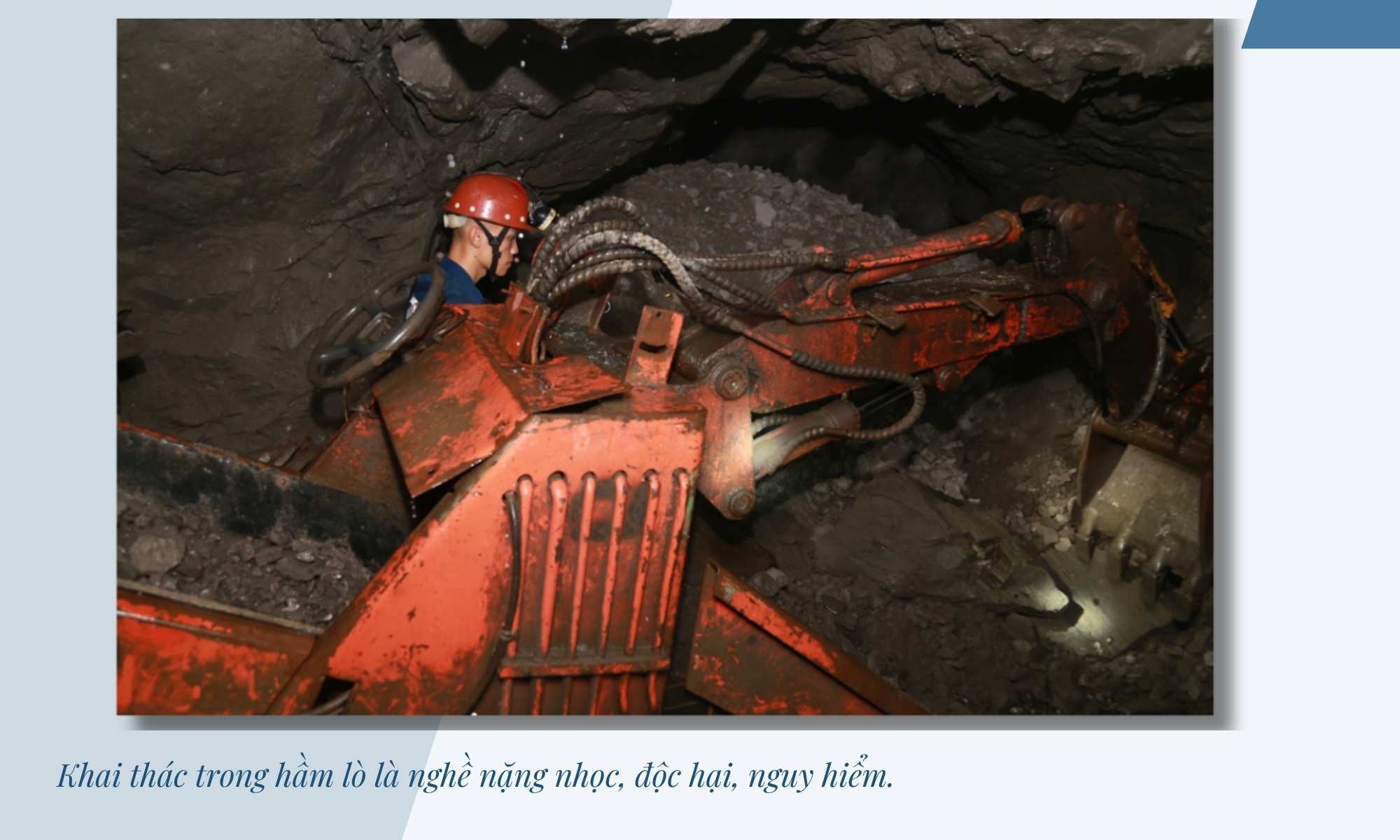

The mining area is deep underground, day and night, workers have to work in a cramped environment, lacking oxygen, lacking light, and always facing danger.

Mr. Mac Van Tien shared: Underground mining is a hard, toxic and dangerous job. Some of the main risks are falling rocks and soil, slipping when walking, especially the risk of suffocation during the production process due to toxic gases generated when drilling and blasting. Therefore, we must implement ventilation measures to quickly disperse toxic gases in the work area.

During the working process, the workshop regularly conducts safety training for staff, workers, and laborers at least 5 times a year. New workers must also undergo a strict 3-step training process according to regulations. The unit also conducts safety supervision during shifts. Each group of workers has a safety and hygiene officer who is specially trained in safety work with labor and production.

Ensuring safety for workers and laborers is also done through developing a reasonable exploitation plan. Based on the branch's production plan, the dispatch department will deploy the workshop to construct and exploit the correct measures given by the branch. This process will be closely monitored to ensure safety for workers and equipment.

Mr. Vu Duc Huong, Deputy Head of the Control Department, Mine Workshop said: Cameras are installed in all locations, from the ground to the production area in the mine to monitor the production process of workers and laborers. When detecting abnormalities, the on-duty department will call the production area, notify workers in the dangerous area to retreat to a safe location and take measures to thoroughly overcome the risks.

Focusing on ensuring labor safety in mining helps the unit limit unfortunate accidents, while helping workers feel secure in their commitment to the unit, thereby improving business efficiency.

Phang A Sinh, a miner, shared: In the first days of working in the mine, I was a bit worried and tired. However, with the encouragement and guidance of my colleagues in the workshop, I got used to the environment. We felt the concern and care for the safety of the workers from the branch leadership team, so we were completely assured in our work. The work was difficult and tiring, but the policies and regimes were guaranteed, and the income was stable, so everyone was determined to stick with the job long-term to contribute more to the unit.

Source: https://baolaocai.vn/dam-bao-an-toan-lao-dong-trong-khai-thac-ham-lo-post401996.html

![[Photo] President Luong Cuong presents the 40-year Party membership badge to Chief of the Office of the President Le Khanh Hai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/a22bc55dd7bf4a2ab7e3958d32282c15)

![[Photo] Prime Minister Pham Minh Chinh inspects the progress of the National Exhibition and Fair Center project](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/35189ac8807140d897ad2b7d2583fbae)

![[Photo] General Secretary To Lam attends the conference to review 10 years of implementing Directive No. 05 of the Politburo and evaluate the results of implementing Regulation No. 09 of the Central Public Security Party Committee.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/2f44458c655a4403acd7929dbbfa5039)

![[VIDEO] - Enhancing the value of Quang Nam OCOP products through trade connections](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/17/5be5b5fff1f14914986fad159097a677)

Comment (0)