For over 20 years, Mr. Sung Trang Tua’s family in Pa Khoang village, Muong Leo commune, Sop Cop district has maintained the traditional blacksmithing craft of the Mong people. With family secrets, the products are sophisticated, sharp and durable, and are favored by customers.

Mr. Tua's family's forge was built right next to his house, about 40 square meters wide. Mr. Tua shared: At the age of 15, I helped my father with some steps in forging knives and learned the trade. When I was 40 years old, my father passed away, and I continued to take over the forging trade. To make a product that is beautiful in design and works well, it must go through many stages, from selecting steel, shaping the blank, heating, forging, tempering, grinding, making the handle, knife sheath... In addition, the length, width of the blade, handle, thickness, and thinness from the handle to the tip of the knife are calculated appropriately when used.

The traditional forge of the Mong people in general and of Mr. Tua's family in particular is made of soil mixed with kneaded straw, then left to dry naturally; the surface of the furnace sags down to hold a certain amount of coal, and there is a round hole on the side of the furnace to blow air into the furnace during forging. The coal used for forging is from longan and chestnut trees. After burning to get coal, the coal is kept in a hole in the ground for a week before it can be used. Depending on the nature of each type of steel, different tempering methods are applied, such as tempering with water, banana tree trunks, pond mud or oil; the blade can be tempered partially or the entire knife can be tempered...

According to Mr. Tua, the most difficult part of the forging process is heating the billet. After heating, the iron billet is brought to the hammer handle. This operation requires strength, speed, and decisiveness in each hammer stroke. If you want the tool to be sharp and not have a cracked blade, you need to temper it to the right degree. Look at the color of the steel after heating to determine the exact time of tempering. The knife sheath is usually made of po mu, ebony or wild mulberry wood, because these types of wood have beautiful grain, tough wood fibers, are easy to shape, and are durable and shiny over time. The knife handle and sheath are reinforced with copper stitches or braided with rattan to increase aesthetics.

In 2020, his family expanded the scale of the forge and equipped it with an electric fan, grinder, stamping machine... Currently, each month, his forge produces 30-40 products, mainly jungle knives, with prices ranging from 250-400 thousand VND/product, with an average income of 7-8 million VND/month, consumed in the commune, district, and province and sent to customers in the provinces of Yen Bai, Lao Cai, Lai Chau, Dien Bien, and Hanoi .

One of the regular customers who order forged knives from Mr. Tua, Mr. Nguyen Van Long, Ngoc Thuy ward, Long Bien district, Hanoi, informed: The products made by him are not only durable, beautiful, and sharp, but also show the heart of someone who wants to preserve the traditional craft of the nation.

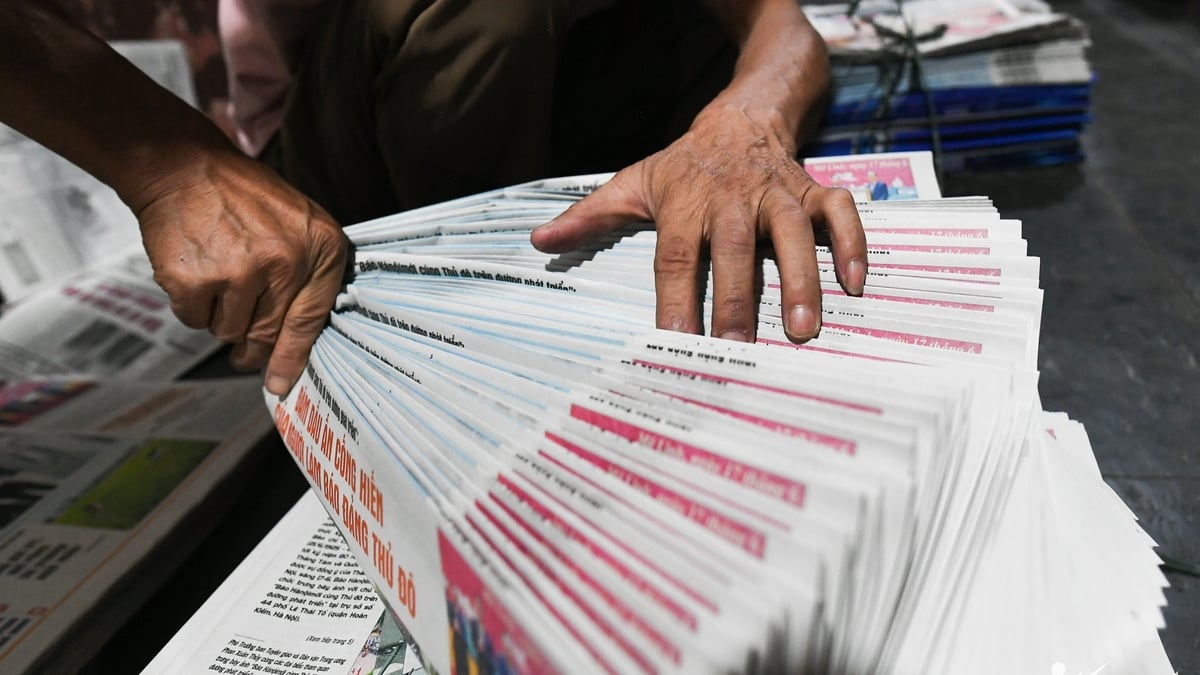

Article and photos: Truong Son

Source

![[Photo] The 9th Congress of the Party Committee of the Office of the President, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/6/20/78e7f27e8c4b4edc8859f09572409ad3)

![[Maritime News] Wan Hai Lines invests $150 million to buy 48,000 containers](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/6/20/c945a62aff624b4bb5c25e67e9bcc1cb)

![[VIDEO] - Quang Nam Business Association and the mission of creating a development environment](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/6/21/098925da24ac4f73a023890b30c5196f)

Comment (0)