|

| After processing, food is divided into servings. |

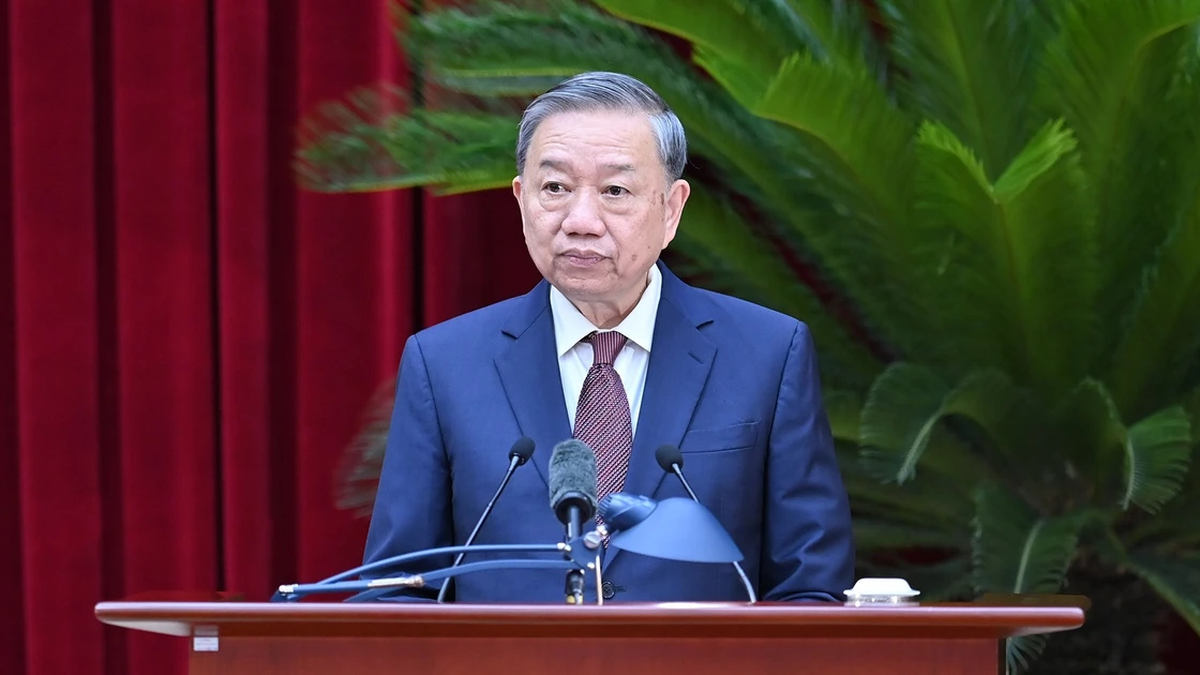

Mr. Vu Xuan Truong, Deputy General Director in charge of business of VAS Group, shared: Food preparation for students must be done very carefully, because it is directly related to the health, even the lives of the children. Therefore, VAS always puts food safety first as a guideline in all activities.

To ensure the quality of 10,000 meals per day, the Company has invested nearly 10 billion VND in the cooking system, applying modern machinery to the maximum to reduce labor and increase the efficiency of food hygiene and safety control. Raw materials are imported from 4 am every day and the entire process from preparation, processing to packaging is operated continuously for about 2-3 hours to ensure fresh, delicious meals delivered to schools on time.

VAS Group says no to ingredients of unknown origin. All food is fully traceable and only cooperates with reputable suppliers such as Meat Deli (for meat) and vegetable farms that meet safety standards.

Before each school year, the Company organizes for school representatives, parent-teacher associations, and people's inspection committees to directly inspect the material supply sites - an action that clearly demonstrates transparency and openness.

The company is equipped with a camera system to monitor the entire process of preparing, processing and transporting meals. Each school is given 10 access cards, allowing parents and schools to monitor directly at any time. This is considered a pioneering step in "empowering" the community to monitor, making parents part of the food safety inspection system.

|

| Meals in warmers are transported to schools. |

Another highlight in VAS Group’s management model is the application of technology to nutritional management. The company builds nutritional software based on standard food rations, and publicly discloses the raw-cooked food table to schools. Each school is also equipped with electronic scales to easily check the actual situation against the contract, ensuring honesty and consistency in providing meals.

Surveying the actual situation of VAS Group in Tan Lap ward, we easily noticed that the kitchen is organized according to the "one-way" model - that is, food goes in a single direction from receiving goods, preliminary processing, processing to packaging, completely avoiding cross-contamination. Areas such as preliminary processing of vegetables, meat, fish, processing, dividing food, and cleaning utensils are all clearly defined, along with standard cleaning and sterilization procedures.

In addition, regulations on work clothes, personal hygiene checks, and vehicle inspections are also strictly implemented. Every step has a record book, a cross-checking department, and periodic comparisons to promptly detect and handle any errors, if any.

Teacher Doan Thi Hoa Binh , Principal of Huong Son Primary School, informed: In the 2024-2025 school year, the school signed a contract with VAS Group to provide about 750 lunches per day. Previously, the school signed a contract with a catering unit at the school, which made us quite worried about fire prevention. Noise and food odors also affected teaching and learning to some extent. Since cooperating with VAS Group, those shortcomings have been clearly overcome.

|

| A lunch for students of Huong Son Primary School ( Thai Nguyen City) provided by VAS Group. |

During the meal provision process, the Company strictly implements its commitment to changing the menu according to the season, and to soliciting the opinions of students and teachers after each meal. All suggestions are promptly accepted and adjusted - such as changing the chicken dish from chopped to boneless to make it easier for students to eat.

In particular, parents have the right to check the source of raw materials and the processing at the Company at any time; once a month, a parent representative comes to supervise lunch at the School. Thanks to delicious lunches, students are more excited about going to school, and parents are also assured to send their children to boarding school.

Mr. Ly Van Canh, Head of Food Safety and Hygiene Department (Department of Health ), assessed: In the context of many challenges in school food safety, the model that VAS Group is implementing is worth replicating.

According to Mr. Canh, to build long-term trust from the community, food production and business units not only need to be dedicated but also need to have vision and transparency throughout the entire process.

In addition, businesses also need to proactively inspect and closely monitor suppliers of input materials to ensure requirements on origin and food safety in all stages - from facilities, equipment, tools to people involved in preliminary processing and processing...

Source: https://baothainguyen.vn/xa-hoi/202505/khi-bua-trua-hoc-duong-duoc-giam-sat-tu-bep-den-ban-73815a7/

Comment (0)