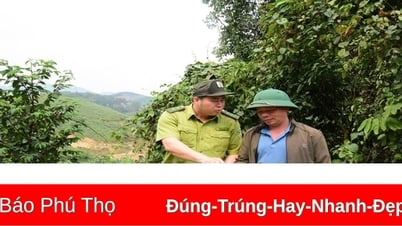

Producing export garments at Thygesen Vietnam Textile and Garment Company Limited - Phu Tho Branch (Yen Lap town industrial cluster, Yen Lap district).

The Phu Tho textile and garment industry has attracted a number of large enterprises, including FDI enterprises, contributing to creating high production value and promoting technological innovation, modernizing production lines, and creating a spillover effect to enterprises in the industry. In recent years, the Phu Tho textile and garment industry has maintained a relatively stable output with an average of over 200 million ready-made garment products, over 50 million square meters of finished fabric and about 15,000 tons of total yarn each year.

To meet the increasing demands of customers and anticipate the development trends of target markets, the application of science and technology in production is becoming an inevitable direction for textile and garment enterprises. Many units in the province have gradually invested in automatic machinery and equipment, digitized some production stages, and increased the use of software in transactions and product design. These are important steps to shorten production time, reduce costs, and increase flexibility in responding to orders.

Phu Tho Textile Company Limited (Thuy Van Industrial Park, Viet Tri City) specializes in producing cotton yarn with an output of about 8,000 tons per year. Mr. Nguyen Van Ha - Director of the Company said: "Our cotton yarn serves both domestic and export markets. Faced with increasingly high technical requirements from garment partners, businesses are forced to upgrade equipment and strictly control the production process to ensure stable quality, meeting diverse customer requirements."

In 2025, with the positive recovery from major markets such as the EU and Japan, many Phu Tho textile and garment enterprises have signed long-term orders and are flexible in production management. In particular, expanding exports to new markets is helping enterprises maintain growth rates and reduce dependence on traditional markets.

Thygesen Vietnam Textile and Garment Company Limited - Phu Tho Branch (Yen Lap Town Industrial Cluster, Yen Lap District) has a production capacity of 5 million products/year, creating jobs for over 400 workers. The company mainly processes ready-made garments such as clothes, hats, socks, towels... for both domestic and export markets. According to Ms. Doan Thi Thu Hien - General Director of the Company, the entire product production process is systematically planned right after receiving the order, from preparing raw materials to processing finished products. The Company's equipment system is invested relatively synchronously, including sewing machines, overlock machines, buttonhole machines, cutting machines of all kinds, laser cutting machines, button attaching machines, needle detectors, automatic heat presses, printers, mex presses, dehumidifiers, thread extractors, fabric spreaders... In addition, the unit also invests in additional auxiliary machinery and equipment to increase productivity, work efficiency and suit production needs and product quality.

However, the textile and garment industry is facing many challenges from the rapid changes in fashion trends, consumer habits and stricter requirements for product quality, sustainability and social responsibility. Consumers today are not only interested in design and price but also pay attention to the production process, origin of raw materials and environmental friendliness. Along with that, fluctuations in tax policies from major markets such as the US can affect the competitiveness and profitability of businesses. Pressure on production costs, delivery schedules and quality also require businesses to constantly innovate.

In this situation, businesses need to continue investing in technology and automation, improving the qualifications and skills of workers. Instead of focusing on popular products that are difficult to compete, businesses need to gradually shift to producing high-tech, high-value-added products. At the same time, businesses need to diversify markets, improve design capacity, proactively source raw materials and develop industry chains; focus on applying international standards on quality and environmental protection, meeting the requirements of demanding export markets.

Nguyen Hue

Source: https://baophutho.vn/nganh-det-may-thich-ung-voi-xu-the-phat-trien-ben-vung-231493.htm

![[Photo] Press delegation meeting to visit Truong Sa and DK1 Platform](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/22/6b8d232877ec421a9e8187d83b9f8006)

![[Photo] General Secretary To Lam chairs a working session with the Central Internal Affairs Commission](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/22/3b7790f499da45b2803d8ae253207ef1)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting on draft Resolution of National Assembly on International Financial Center in Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/22/d398664ff1a140629169ea5a24e1b4d0)

![[Photo] T&T 1 and Ho Chi Minh City 1 People's Police Teams won the men's and women's team championships](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/22/39db06ae67cb4001b7a556e8d9a56d07)

![[Podcast] Week introducing more than 500 OCOP products in Hanoi](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/22/d144aac2416744718388dbae3260e7fd)

Comment (0)