Mr. Bui Manh Cuong in Ngoc Lien commune, Cam Giang district, Hai Duong province is a billionaire who raises pigs using biological bedding - a technology he "learned" from the Netherlands. Many years ago, he successfully applied the model of raising pigs using biological bedding, earning billions from selling pig manure through biological bedding alone.

Went to the Netherlands to learn how to make biological bedding at a chicken farm and then applied it to large-scale pig farming.

In 2023, Mr. Bui Manh Cuong in Ngoc Lien commune, Cam Giang district, Hai Duong province was honored as an Outstanding Vietnamese Farmer by the Central Committee of the Vietnam Farmers' Union .

After more than a year of not meeting Outstanding Vietnamese Farmer 2023 Bui Manh Cuong, we anxiously wondered how his production and livestock situation was?

During this reunion, Cuong told us that during that time, he had to struggle with many difficulties due to pig diseases, low pork prices, and high feed ingredient prices, causing farmers to suffer losses.

Then storm number 3 came and in a flash, it also "blew away" a few more billion dong from him.

However, mixed with the difficulties and losses, he also had some joy to encourage.

Recently, Mr. Cuong's Thanh Dong Grape product was recognized as 3-star OCOP by the People's Committee of Cam Giang district.

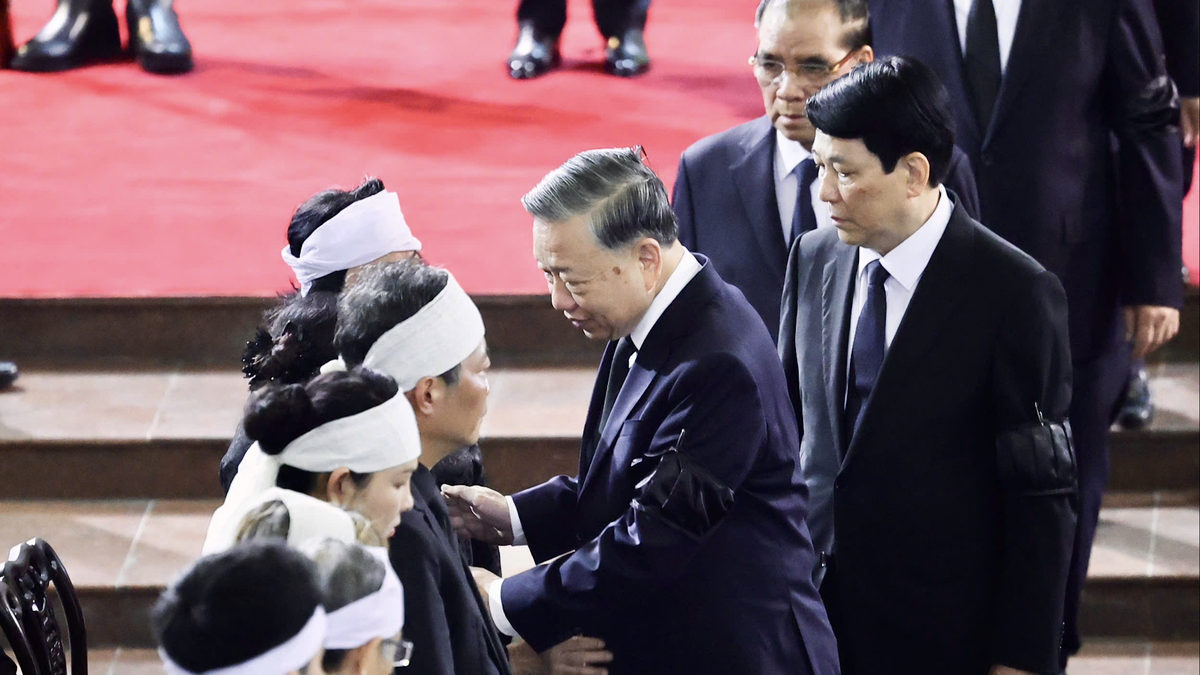

Mr. Bui Manh Cuong, a billionaire farmer in Ngoc Lien commune, Cam Giang district, Hai Duong province, and workers check a pig pen using biological bedding. Photo: Nguyen Viet.

Returning to the story of large-scale, modern pig farming, Mr. Cuong also affirmed that the important factor that has helped the farm's farming in recent years is the experimental and successful application of the biological bedding model to large-scale pig farming.

Mr. Cuong said, in 2014, he was invited by a Dutch corporation to visit pig and chicken farming models in the neighboring country. In addition to visiting pig farms and modern technology, Mr. Cuong also visited a chicken farming model. During the visit, he noticed that there was no smell in the chicken coop.

After learning, Mr. Cuong learned that they raise them using biological bedding, the raw material is the bedding material in the coop. When the chickens excrete, it will be treated with probiotics and mixed with the bedding. Therefore, there is no more smell in the coop.

He finds this method very good for keeping the coop clean. This helps reduce the risk of chicken diseases and environmental pollution.

However, it took Mr. Cuong 2 years to apply it. In 2016, Mr. Cuong tested biological bedding in a 500 m2 barn to raise piglets. Because in those 2 years, he invested in applying advanced and modern Dutch livestock science and technology, so he had not yet used biological bedding in pig farming.

Mr. Cuong confided: At first, making bedding was very difficult. When applying biological bedding to raise pigs in the 500 m2 of the experimental farm, he used 2/3 of the area of the barn to make biological bedding. He dug the bedding area 60cm deep to put sawdust down and release microorganisms to treat waste.

Building a piglet pen was successful, but in 2018, when applying bedding for raising large pigs, problems arose.

Big pigs excrete a lot of waste, the litter gets clogged quickly and the probiotics cannot process it fast enough, so the pens stink. In addition, when turning the litter, you have to do it manually, using hoeing and raking, which is very hard and smelly. Each time you turn the litter, it takes 5-6 workers to hoe, turning like that is too much effort."

After that, Mr. Cuong had to go to the house of Mr. Pham Van Hat, an expert in inventing agricultural machinery and equipment in Tu Ky district (also in Hai Duong province) to order Mr. Hat to invent a specialized plow to turn the bedding.

The specialized plow for turning bedding was born, and the test was successful. However, to be applied more conveniently and effectively, Mr. Cuong thought and improved some details to suit the farm's barn conditions.

Since the tractor was available, plowing and turning the litter in the pig pens has become faster, the workers have less work, and the pig pens do not have bad odors. Only then did Mr. Cuong consider the application of biological litter in pig farming a success.

Mr. Cuong has applied biological bedding to other pig pens. Up to now, the total area he has applied as biological bedding in pig farming is more than 8,000 m2 .

From the patent of the litter plow of Mr. Pham Van Hat (Mr. Cuong bought the patent of Mr. Hat) and with further improvements, Mr. Cuong has produced more than a dozen litter plows for use in other barns. The number of barns using biological litter, Mr. Cuong uses to raise piglets and pigs for meat.

When implementing bedding for the entire area of 8,000 m2 , Mr. Cuong followed the technical standards: 1/3 of the barn was made of concrete, 2/3 of the barn was made of bedding.

Workers at Mr. Cuong's pig farm are sprinkling probiotics on biological bedding. Photo: Nguyen Viet.

The area used as bedding is 1.2 m deep, spread a layer of rice husk, water it warm, sprinkle microorganisms to inoculate the yeast, continue to pour 30 cm thick sawdust, then water it moist again, sprinkle microorganisms. The farm workers repeat this process until the bedding is 1.2 m high, equal to the concrete floor.

In the following batches, after selling the pigs, the areas with a lot of manure are moved to the areas with little manure, then plowed to make it smooth, then yeast is sprinkled, plowed, and watered. Usually after selling the pigs, the bedding is also sunk 20-30 cm deep, at which time the workers add rice husks, water, and sprinkle yeast to level the concrete floor. During the raising process, any sunken areas are filled with more rice husks.

The bedding is always checked, the humidity is sprayed with mist, the humidity is hosed. Every day, workers mainly water the bedding to ensure humidity so that when the pigs are in the bedding, they do not get dusty, affecting the respiratory process.

For piglet pens, workers usually plow, sprinkle yeast once every 3 days, and water once every 2 days for piggeries that are about to be sold.

Dan Viet reporters went into the barn with biological bedding, and their first impression was that although it was a closed barn, there was no foul smell. Observing the workers operating the plow to turn the bedding, they found that the workers worked very leisurely.

Billionaire raises pigs with "odorless technology"

Talking about the effectiveness of the biological bedding pig farming model, Mr. Bui Manh Cuong, owner of a pig farm in Ngoc Lien commune, Cam Giang district, said that raising pigs on biological bedding will save on farming costs.

For example, if you build a standard, fully concrete-floored livestock barn, it will cost more than building a bio-bedding barn. Concrete-floored barns are more expensive because they require more space and the cost of building a wastewater treatment system and environmental sanitation.

Mr. Bui Manh Cuong, a billionaire who raises pigs using biological bedding in Ngoc Lien commune, Cam Giang district (Hai Duong province), sits inside a pigsty to check the biological bedding. Photo: Nguyen Viet.

If the barn system is larger than 20,000 square meters, an additional 14,000 square meters must be reserved for building a biogas tank system, settling tank, and lake.

Of the total cost of about ten billion, the cost of building a wastewater treatment system costs from 3 to 4 billion VND. In addition, in the process of raising pigs in concrete pens, more water and electricity will be used for spraying and cleaning the pens, and lighting to keep the pigs warm in the winter.

Raising pigs in biological litter pens will be more economical, because there is no need to build a wastewater treatment system, only need to buy popular bedding materials such as rice husks, sawdust, and treated yeast; during the raising process, electricity and water costs will be less.

Moreover, after 4 years, the new bedding must be replaced, the old bedding mass will be collected and turned into fertilizer to be sold to farms and gardeners to fertilize plants. This fertilizer is very good for fields and plants.

Mr. Cuong said, "Like recently, I replaced the new bedding, I collected more than 500 tons of fertilizer from the old bedding, sold it at a market test price of 2,000 VND/kg, I also earned a billion VND from selling fertilizer."

According to Mr. Cuong, pigs raised on biological bedding develop better and gain more weight than pigs raised on concrete floors during the same period.

In particular, the litter-based pig pens are odorless and do not pollute the environment. The biological litter-based pig farming model is very suitable for large-scale farming and the strict environmental requirements of today.

Mr. Bui Manh Cuong boldly experimented with raising pigs on biological bedding and succeeded, helping to make farming more effective and not pollute the environment. Reported by: Nguyen Viet.

Mr. Le Quy Quynh, Chairman of the Farmers' Association of Cam Giang district (Hai Duong province) said: After many years of implementing the biological litter pig farming model of Mr. Bui Manh Cuong, its effectiveness has been confirmed.

Raising according to this model has helped him reduce many costs in building barns, raising livestock, and increasing income. In particular, this model also helps reduce environmental pollution.

Mr. Quynh also added that Mr. Bui Manh Cuong is also a typical example of good production and business for many years in Cam Giang district in particular and Hai Duong province in general.

In 2023, Mr. Bui Manh Cuong was honored by the Central Committee of the Vietnam Farmers' Union as an Outstanding Vietnamese Farmer.

In a few days, Mr. Cuong will join a delegation of officials and members of the Farmers' Association of Cam Giang district to attend the conference summarizing the "Movement of farmers who are good at production and business, unite to help each other eliminate hunger, reduce poverty and enrich themselves legitimately" in the whole province organized by the Farmers' Association of Hai Duong province.

Source: https://danviet.vn/ong-ty-phu-hai-duong-nuoi-lon-bang-cong-nghe-dem-lot-sinh-hoc-ha-lan-chi-ban-phan-da-thu-tien-ty-20241214163446478.htm

![[Photo] Ho Chi Minh City holds funeral for former President Tran Duc Luong](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/24/9c1858ebd3d04170b6cef2e6bcb2019e)

![[Photo] Party and State leaders visit former President Tran Duc Luong](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/24/960db9b19102400e8df68d5a6caadcf6)

Comment (0)