Struggling to get orders in the common situation of "hungry for orders and lacking capital", businesses are now afraid of not being able to deliver on time due to lack of electricity.

Over the past two weeks, the power shortage crisis has spread across all sectors and industries in the North. Mr. Nguyen Minh Chau, Director of Hanoi CNC Precision Mechanical Company (Quang Minh Industrial Park, Me Linh, Hanoi), shared that the power outage is adding more burden to businesses in the context of an unfavorable capital market.

2023 is the time when businesses are exhausted due to lack of orders, lack of capital, and high input costs. Statistics up to the end of May show that more than 88,000 businesses have left the market; and a survey by VnExpress and the Private Economic Development Research Board (Board IV) with nearly 10,000 businesses also showed that 82% plan to reduce scale, suspend or stop business in the remaining months of the year.

"This year's economic recession has led to a decrease in orders. If you are lucky enough to get an order or project, the requirements are short and urgent," said Mr. Chau. However, sudden power outages or untimely notices make businesses passive, making it difficult to complete orders on time, losing credibility with customers.

"Electricity is an extremely important input in production. But the current load reduction will cause us a lot of difficulties in the post-Covid-19 recovery period," he said.

Bamboo weaving workshop empty of workers due to power outage on June 2. Photo: Gia Chinh

Mr. Vu Khac Tiep, Deputy Director of Song Phuong Production and Trading Joint Stock Company, commented that power outages are adding more burden to businesses in the period of trying to recover from the pandemic.

He said that to increase production capacity, last year, Song Phuong modernized the factory so that 90% of the production line uses electricity. The recent power outage caused the company's production capacity to drop by 40%.

Power outages also cause other business costs to increase dramatically. "Workers have to take breaks in the middle of their shifts while businesses still have to pay salaries, arrange overtime work, leading to increased labor costs," he listed.

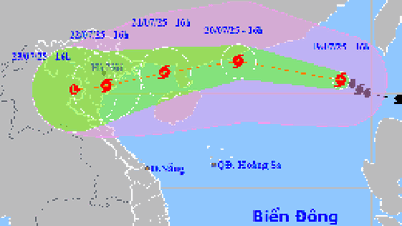

In the near future, this enterprise has orders to China and Europe, but instead of being happy, Mr. Tiep expressed his concern because the production point falls right at the peak of the hot season, the possibility of long power outages, more dense, can affect the quality and cost of goods. According to the Ministry of Industry and Trade , the North is currently at risk of "power shortages most hours of the day" because the demand exceeds the available capacity of all sources (including imported electricity). It is estimated that each day there is a shortage of 30.9 million kWh and the highest day can be up to 50.8 million kWh.

"If the power outage lasts long, the possibility of losing contracts to businesses in the southern market is very high," Mr. Tiep shared.

Not only domestic manufacturing enterprises are struggling, many large FDI enterprises are also miserable when production stagnates and costs increase due to unstable electricity.

Speaking to VnExpress, Mr. Hong Sun, Chairman of the Korean Business Association in Vietnam (Kocham), said that many Korean businesses are suffering from power outages 2-3 times a week.

"Power outages take up half a working week, causing businesses to be unable to produce, orders to be delayed, machinery and goods to be damaged, while fixed costs still have to be paid," he said. These are assessed by the Korean business community as causing significant damage.

Currently, Korean businesses are worried about having to pay compensation if they fail to deliver on time. "Many businesses are afraid of prolonged power outages. They can endure a few days to a month, but a continuous power cut of 40-50% is very dangerous," said Mr. Hong Sun. Currently, the association representing nearly 10,000 Korean businesses in Vietnam has sent a petition to Prime Minister Pham Minh Chinh for remedial measures.

The service sector has also been affected by the power outage. Mr. Pham Quoc Long, Chairman of the Vietnam Association of Shipping Agents, Brokers and Services, said that the power shortage has caused cargo congestion at seaports in the North, causing losses for many parties.

For example, at Hai Phong port, on a normal day, the port will clear about 15,000 TEUs (15,000 20-foot containers), equivalent to 8-9 ships. Loading and unloading time is about 20 hours for a ship.

"If a ship enters the port without electricity to serve, it will cause a traffic jam. The damage to the port and shipping lines is about 30,000-40,000 USD per ship. With about 20-30 ships coming in and out every day, the damage is not small," said Mr. Long.

In addition, according to him, ports have invested heavily in high technology, using electricity instead of gasoline, at great cost. Therefore, frequent power outages not only directly affect the production and business activities of each port but also affect the reputation of the quality of seaport services compared to the region and can lead to a loss of confidence in the national energy security system.

Major supermarkets and shopping malls have also been disrupted due to power outages. Ms. Nguyen Thi Bich Van, Communications Director of Central Retail Group, said that since the beginning of summer, Cau Giay District Electricity, Hanoi has cut off power twice at Big C Thang Long shopping mall. The reason for the power outage was "to reduce the load for about 2 hours".

The power outage forced Big C to use generators and cut down on air conditioning in most areas of the mall, and even shut down the Bread Oven and Chicken Oven systems. This affected the supermarket's production and business.

AEON Long Bien Shopping Center also suffered two power outages in early June. The company representative said that when there was a power outage, the generator would operate to maintain the refrigerator, freezer, lighting, and cashier systems in the supermarket area. However, in the shopping center area, due to insufficient electricity, some stalls had to close or temporarily suspend operations, and the air conditioning system could not be maintained as usual.

To cope with the power shortage , manufacturing and service businesses are focusing on cutting down, saving energy, rearranging production and seeking support from partners.

Mr. Chau said that Hanoi CNC is minimizing the use of electricity in the factory; adjusting the working schedule of workers to overcome and maintain some production activities; asking to extend the time to complete orders within the allowed range. Song Phuong Company is also looking for a solution to arrange rotating shifts, cutting some steps from machines to manual work.

Mr. Tran Van Nam, General Director of MBT Electronic Equipment Joint Stock Company, said that to maintain its reputation with customers, in case of prolonged power outages, the company will invest in additional generators to ensure order progress. However, he said that this solution is only temporary as the investment in generator operating costs affects the production cost and business efficiency of the company.

Meanwhile, General Director of Sao Viet Mechanical Technology Joint Stock Company (Savimec) Ngo Sach Vinh shared that the unit has begun to consider the option of investing in renewable energy to meet production plans and meet delivery schedules. However, this will increase product prices and reduce competitiveness.

Currently, businesses all have a common request for the Government to end the power outage to ensure the need for stable production activities. In case of force majeure, businesses want to have a specific and accurate notice of the power outage schedule early so that they can be proactive in production and business.

Phuong Anh - Anh Minh - Thi Ha

Source link

![[Photo] National Assembly Chairman Tran Thanh Man visits Vietnamese Heroic Mother Ta Thi Tran](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/20/765c0bd057dd44ad83ab89fe0255b783)

Comment (0)