Ho Chi Minh City Master Ho Gia Thien Thanh, 26 years old, researches gold nano catalysts to reduce toxic p-nitrophenol in wastewater into non-toxic form, applicable to the pharmaceutical industry.

Thanh is currently working at the Department of Process Equipment and Catalysis, Institute of Chemical Technology, Vietnam Academy of Science and Technology. Since the end of 2022, Thanh has researched and proposed a process for manufacturing gold nanocatalysts using a green method called ceria nanorods for the removal of p-nitrophenol (PNP) in wastewater. PNP is a toxic organic compound found in wastewater from dyeing, pharmaceutical, food processing industries... The US Environmental Protection Agency has classified it among the 114 most dangerous organic pollutants and is potentially carcinogenic.

Thanh's method of treating p-nitrophenol is to use a catalyst to convert the nitro radical into an amine radical, which means converting PNP into p-aminophenol (PAP). The resulting PAP can be used as a precursor in pharmaceuticals, such as the preparation of paracetamol.

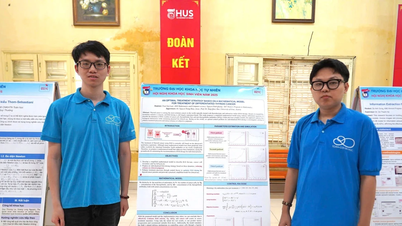

Master Ho Gia Thien Thanh at the laboratory of the Institute of Chemical Technology, Vietnam Academy of Science and Technology (District 12, Ho Chi Minh City). Photo: Ha An

The author said that in traditional research, the fabrication of gold nanoparticles often uses chemical reducing agents such as Sodium borohydride (NB), which is toxic and expensive. To replace this NB reducing agent, Thanh used grapefruit peel extract containing many polyphenol compounds that can reduce gold ions into gold nanoparticles.

In addition, to increase the efficiency of converting PNP into PAP, the author used nanorod ceria as a carrier to help disperse the gold nanoparticles. This reduced the processing time from one hour to 30 minutes. "This method makes the PNP reduction process greener, saves costs and takes advantage of natural by-products," Thanh said.

With gold nanoparticle content from 0.1 to 0.2% on ceria carrier, gold nanocatalyst works effectively, PNP reduction process can reach efficiency over 99% in laboratory scale.

After 5 test batches, the catalyst still retains its activity and efficiency, thus reducing costs significantly. After each batch, the catalyst will be separated by centrifugation and used for the next batch.

The author said that the recovery efficiency of PAP, a useful precursor in the pharmaceutical industry, has not been calculated because it is in the early stages of optimizing the manufacturing process and ingredients.

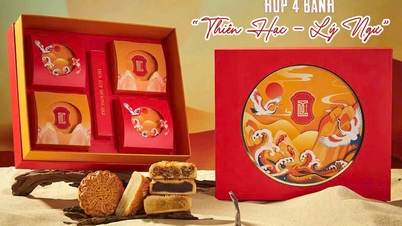

Product used to remove PNP in wastewater researched by Thanh. Photo: Ha An

According to Dr. Nguyen Tri, Institute of Chemical Technology, Vietnam Academy of Science and Technology, the use of catalysts to process PNP into PAP is not a new research direction in the country. However, the novelty of this research is the application of a green method, using plant extracts, specifically grapefruit peel, a common by-product for the synthesis of gold nanoparticles attached to ceria carriers. With low gold content but high efficiency and stable catalyst durability.

To achieve higher applicability, Dr. Tri said that the author needs to manufacture catalysts in pellet form or attach them to a carrier base for easier recovery. This study also needs to be tested on a larger scale with wastewater to evaluate the impact of other substances in the water on the efficiency of PNP removal.

The research under the Youth Innovation Incubator Program of Ho Chi Minh City Youth Union has just been accepted with excellent results. Associate Professor, Dr. Nguyen Thi Phuong Phong, Chairwoman of the Professional Council, highly appreciated the author's use of grapefruit peel extract to reduce gold salt into gold nanoparticles, applying it to convert toxic substances into non-toxic substances, applying it to the pharmaceutical industry.

Current PNP treatment methods mainly use adsorption technology, but must go through the next step of adsorbent treatment. Other traditional methods use many types of chemicals, which are expensive and affect the environment.

VnExpress.net

Comment (0)