This year's event was held under the theme "Science and Technology - The Key to Promoting Circular Economy". The presentation from TH Group's representative completely captivated the audience with practical stories about the application of initiatives and solutions towards green economy and circular economy in the closed value chain from green pastures to fresh milk products serving consumers.

Be determined to “Cherish Mother Nature”

Starting by sharing the message of Labor Hero Thai Huong, TH founder, Mr. Arghya Mandal, General Director of TH Milk Joint Stock Company said that from the very beginning until today, the founder of TH has shown consistency with the Group's motto, vision and mission. That is, "Cherish Mother Nature, who will give you everything".

|

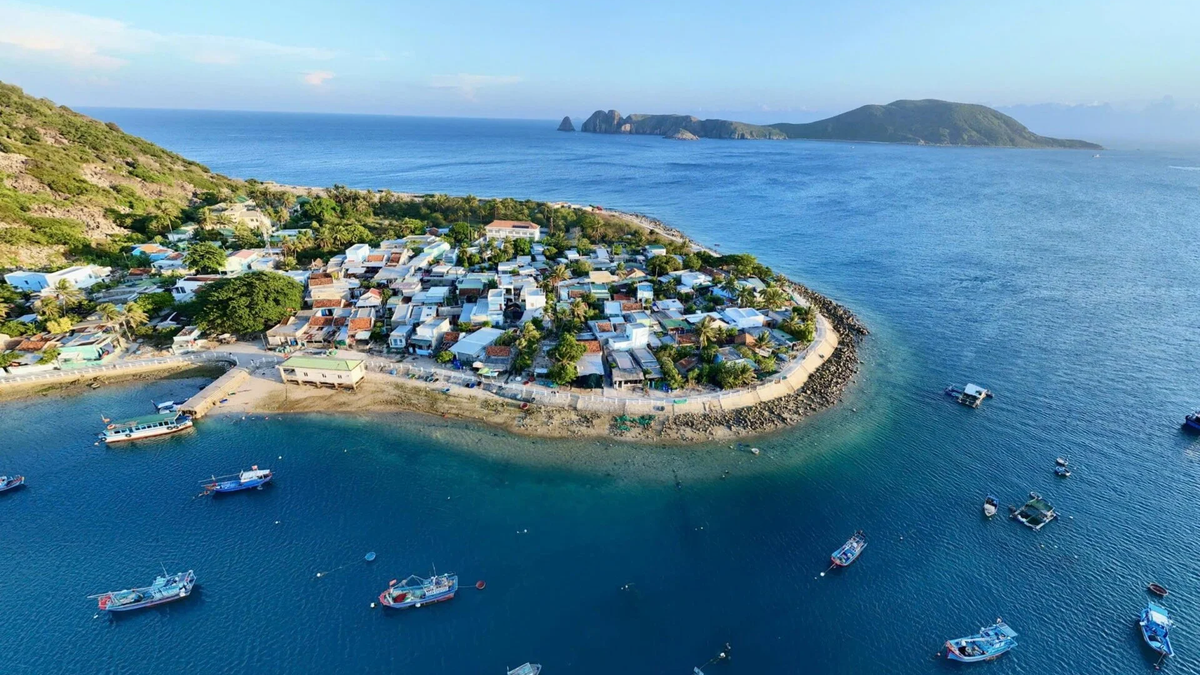

| TH Group's high-tech concentrated dairy farming project, implemented since October 2009 in Nghia Dan, Nghe An, operates along a production chain from green pastures to clean glasses of milk. |

TH’s investment projects focus on the application of high technology, science and technology, and management science intertwined to create agricultural products with breakthrough output and quality in the direction of sustainable development and health benefits. It can be affirmed that TH is successful with a production and business model with very low emissions.

|

| Mr. Arghya Mandal, General Director of TH Milk Joint Stock Company, decoded the circulation models in each member unit of TH Group. |

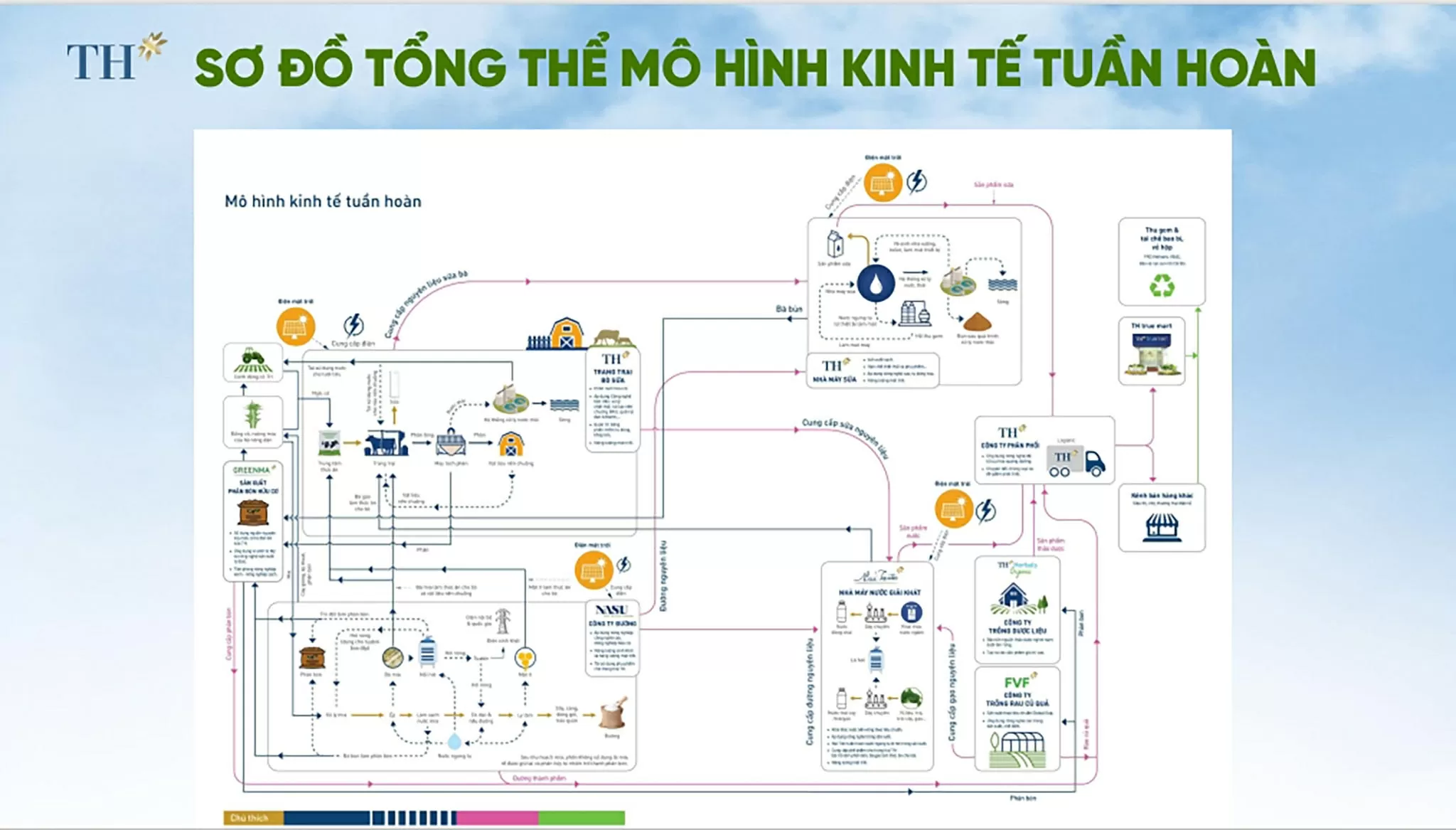

Mr. Arghya Mandal took the PRO Vietnam event hall from one surprise to another when he deciphered the circular economy diagrams at TH Group. Typical examples include circular models at dairy farms; circular models in the processing chain; circular models in product distribution; circular models for producing electricity from sugarcane bagasse; and models for utilizing raw materials/by-products from units within the Group.

In such a circular process at TH Group, almost all raw materials or waste products are not discarded but become resources and input materials for another process.

The General Director of TH Milk Joint Stock Company cited that TH farms supply milk to dairy factories. Livestock waste from the farm is treated and transferred to an organic fertilizer factory, creating a source of fertilizer that is returned to serve farming on the farm itself, as well as supplying to growing units such as FVF (vegetables) and TH Herbals (medicinal herbs).

This is the spirit of “internal circulation” - helping to reduce costs, maximize resource utilization and reduce emissions, creating economic value while protecting the environment.

|

| TH is using German organic fertilizer technology, the most modern technology in the world for fertilizer production today, with the ability to help reduce methane (CH4) emissions. |

Currently, every day, TH's factory processes about 1,000 tons of waste with 70% humidity, from the manure of more than 60,000 dairy cows on the farm, plus leftover food, bagasse and biological sludge generated during the wastewater treatment process of the farms. During the aerobic treatment process with mixing to make fertilizer, the water will evaporate due to the decomposition of microorganisms, creating heat and loosening the waste source. Thus, from the initial 1,000 tons of waste, by the end of the process, the finished product is about 262 tons of green fertilizer with the moisture content in the fertilizer remaining at only about 30%, which is up to standard. |

|

Looking at TH's circular diagram, right from the starting point on the field, Mr. Arghya Mandal said, TH uses Greenma organic fertilizer, a product from dairy cow waste from TH farms, during the cultivation process. The raw materials are then brought to the feed center, silaged, and optimally mixed with advanced Israeli technologies such as RationAll and One1. In this circular process, according to Mr. Arghya Mandal, it helps increase feed efficiency, reduce costs and improve milk quality.

Talking about the world's leading technologies that TH invests in green production, according to Mr. Arghya Mandal, it is impossible not to mention the effective operation of the wastewater treatment system.

TH representative revealed that TH uses exclusive Dutch wastewater treatment technology, with the function of stirring and aerating wastewater at high capacity; has a Biomass system with aerobic technology to help create a clean gas source, which can be used to generate electricity or operate machinery on the farm.

After treatment, the water that meets the standards is returned to the environment, fields or reused to water plants, wash barns – helping to save significant water costs. The solid waste and sludge from this process are processed into organic fertilizer or bedding, returned to fields and farms, acting as “double value loops” – both reducing costs and creating new sources of income.

Technology is the “key” to developing a circular economy

If in the PRO Vietnam annual conference hall, each circular process in the closed production chain that creates the TH true MILK brand is decoded one by one, then in the conference hallway, guests can touch the real products of those processes.

This is also an attraction for visitors to stop at the TH Group's sustainable development exhibition area at this event.

Ms. Mai Pham from the World Wildlife Fund (WWF) could not hide her excitement when discovering the card game about wild animals. The interesting thing is that these toys are recycled from very familiar milk cartons. This is one of the products from the campaign Collect cartons, spread green living that TH is implementing at TH true mart stores in Hanoi, Nghe An and Ho Chi Minh City.

|

| A customer learns about recycled products from the campaign Collecting boxes, spreading green living being implemented at TH true mart stores. |

Ms. Nguyen Thanh Thuy, from a plastic bottle recycling unit, said she was quite curious after Mr. Arghya Mandal's presentation about the technologies operating in TH Group's milk factory, which are all processing and packaging technologies from the world's leading corporations such as Siemens, Danfoss, Grundfos, along with Tetra Pak, GEA, BOSCH, SERAC... These technologies not only ensure high product quality and safety, but also help optimize energy, water and raw material consumption, thereby reducing production costs and environmental emissions.

This made Ms. Nguyen Thanh Thuy not hesitate to express the idea of cooperation to recycle the packaging of TH products such as TH true WATER, TH true JUICE milk...

Within the framework of the PRO Vietnam 2025 Annual Conference, TH Group also offers a 360 farm tour experience through interactive screens, helping visitors learn more about each circular process in the Group's closed production chain.

|

| Visitors enjoy the 360 farm tour to learn about the circular economic model of TH Group. |

The “hearing and seeing” experiences right at the event convinced guests of TH’s success in applying modern technology in the world to the circular economic model.

The most concrete evidence of TH's production and business model with very low emissions is that two member units, TH Milk Joint Stock Company and Nui Tien Pure Water Company Limited, have achieved carbon neutrality according to the international standard PAS 2060:2014, assessed and confirmed by Control Union from 2024.

By investing in end-to-end technology, TH now holds the “key” to developing a circular economy. This is also the way TH accompanies and supports the Government’s message of “commitment combined with action” in the process of implementing the goals towards “Net Zero”.

Source: https://baoquocte.vn/giai-ma-nhung-cong-nghe-hang-dau-trong-mo-hinh-kinh-te-tuan-hoan-phat-thai-rat-thap-cua-th-true-milk-317654.html

Comment (0)