Accelerating digital transformation

Mr. Nguyen Liem, Chairman of Binh Duong Wood Processing Association, said that the current challenges for businesses are increasingly fierce competition in the market, strict requirements on carbon emissions... These factors have increased production costs and reduced profits for businesses. Industry associations and businesses proposed to consider policies to support production development and more effective digital transformation for businesses to meet current requirements.

Mr. Park Se Yeol, General Director of Orion Vina Food Co., Ltd., shared that upgrading a nearly 30-year-old factory into a smart factory, applying technologies such as the Internet of Things (IoT), artificial intelligence (AI) ... is a big challenge. However, Vietnamese engineers at Becamex IDC Corporation and VNTT have demonstrated their confidence, capacity and ability to implement. Orion's experience is to cooperate with experts in its direction to get the best results.

“Currently, the project has almost completed phase 1. In the next phase, Orion will aim to complete a comprehensive automation system, operating and managing production through MES systems, connecting to the overall ERP management system. The ultimate goal is to build autonomous production lines, and surplus human resources will be trained to monitor the operation of smart lines,” said Mr. Park Se Yeol.

Contribute to support businesses

Ms. Phan Thi Khanh Duyen, Deputy Director of the Department of Industry and Trade, said that the digital transformation revolution with 4.0 technology, in which the transition from traditional factory systems to smart factory operating models has been taking place strongly, helps related departments to be more proactive in balancing resources and orienting production plans in accordance with delivery deadlines.

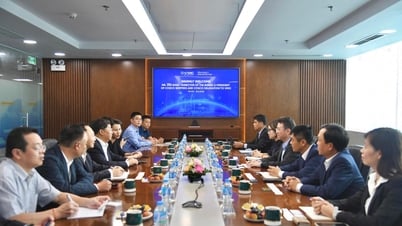

Recently, in April 2025, the provincial leaders chaired a meeting with the leaders of Samsung Electronics Vietnam Co., Ltd. to discuss cooperation in implementing the "Smart Factory Development Support Project in Binh Duong". At the meeting, representatives of Samsung Electronics Vietnam Co., Ltd. shared the results of the implementation of the smart factory development support project over the past 3 years, as well as the results and limitations of the project. In 2025, Samsung Electronics Vietnam Co., Ltd. plans to support the development of smart factories for enterprises with the potential to become suppliers for the company in the future. Supporting industry enterprises can supply Samsung Company in the field of manufacturing phones, televisions, refrigerators, washing machines, and robot vacuum cleaners.

Mr. Shim Sang Yong, Director of Partner Support Department, Samsung Electronics Vietnam Co., Ltd., said that the criteria for selecting enterprises to support the development of smart factories include criteria on industry, number of employees, human resources, determination of the enterprise's leadership, financial situation to invest in building smart factories. The company also shared about different methods for enterprises to choose to develop smart factories, the selection process, project implementation time, progress of supporting projects, etc.

| Mr. Park Se Yeol, General Director of Orion Vina Food Company Limited: “We highly appreciate the smart factory solution developed by Becamex IDC Corporation and VNTT, with modern architecture, full and smart functions, fully meeting strict international standards, not inferior to international solutions, but at a reasonable cost. In particular, upgrading our nearly 30-year-old factory to a smart factory, applying technologies such as IoT, AI, Big Data is a big challenge. However, the Vietnamese engineers at Becamex IDC and VNTT have shown us their confidence, capacity and ability to implement very well”. |

TIEU MY - ANH TUAN

Source: https://baobinhduong.vn/ho-tro-doanh-nghiep-phat-trien-san-xuat-ben-vung-a346569.html

Comment (0)