Handcrafted designs on paper

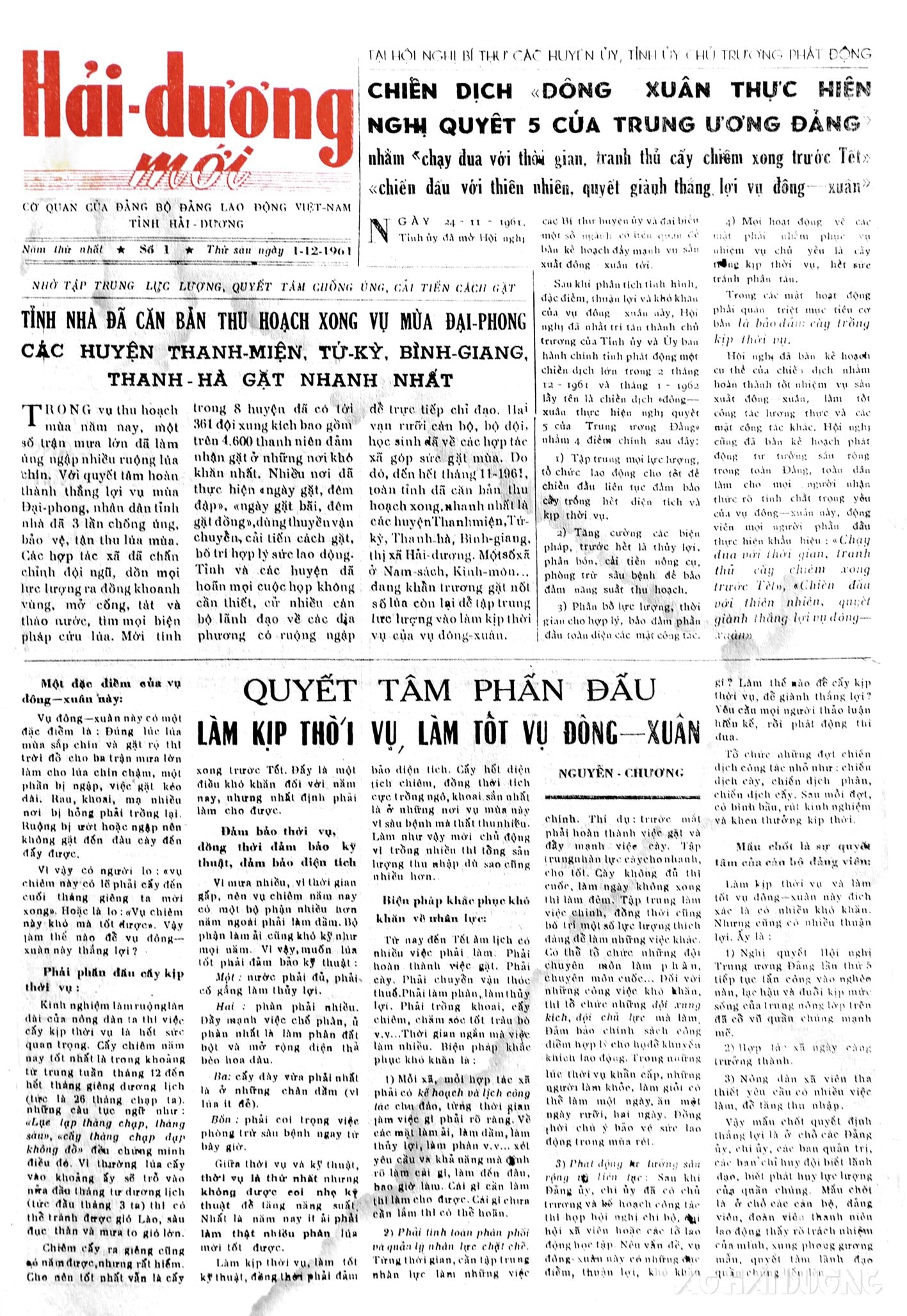

On December 1, 1961, the Hai Duong newspaper published its first issue. Because there was no artist, the reporters had to draw the masthead, write the column layouts, and design the newspaper themselves.

Journalist Nguyen Huu Phach, one of the first four reporters of the Hai Duong Newspaper, was assigned this responsibility. He said: "The drawing and design were done manually on paper using approximate calculations. Therefore, the accuracy was not high." Later, the editorial office sent someone to learn how to draw grids and calculate characters at the Nhan Dan Newspaper to apply the techniques.

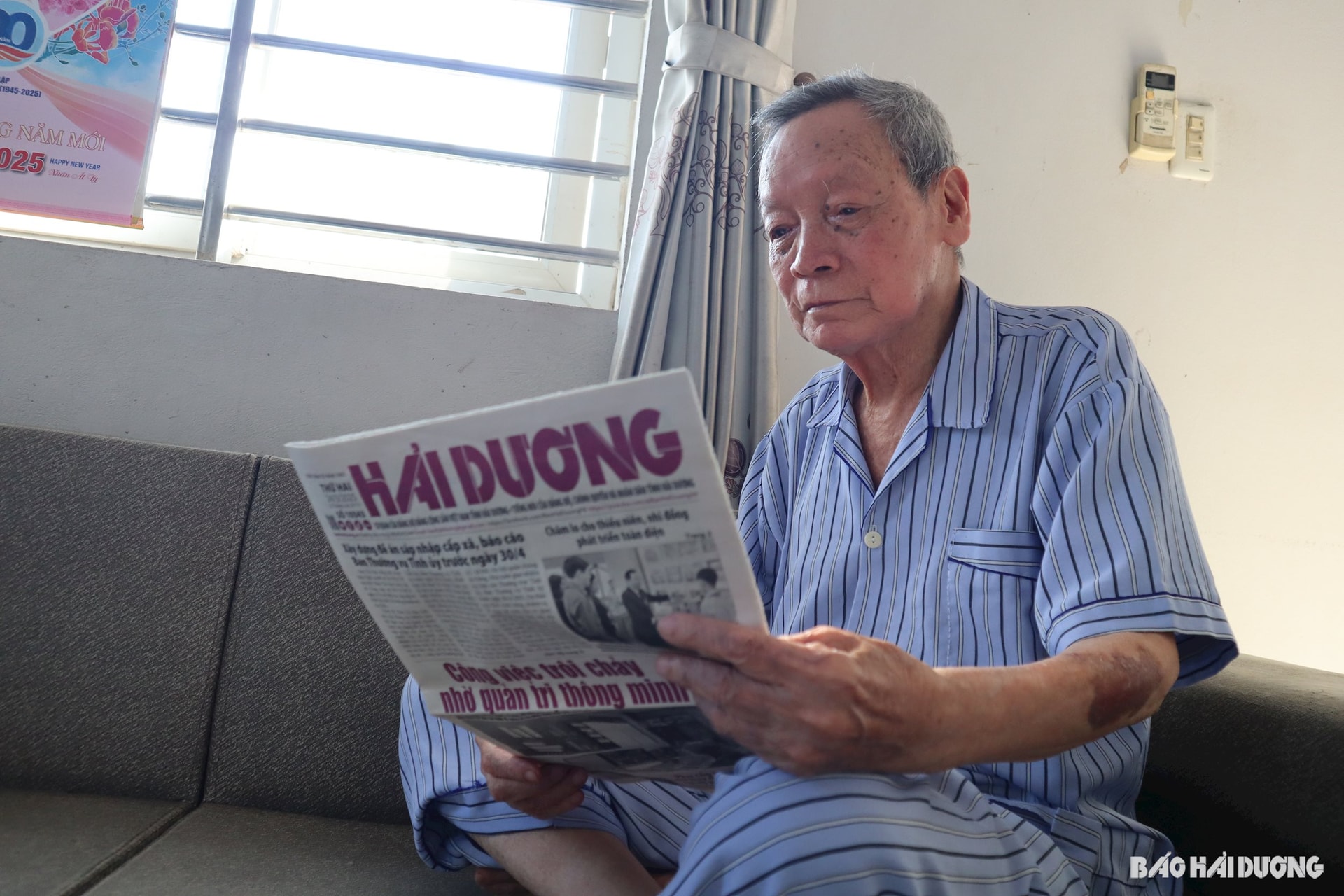

Journalist and poet Ha Cu, former Editor-in-Chief of Hai Duong Newspaper, recalled that in 1976, he joined Hai Duong Newspaper (then Hai Hung Newspaper) as an artist. After reporters' news articles were approved, he would arrange them on a large layout sheet, the size of a newspaper. Each layout sheet was divided into 50 boxes, each corresponding to 50 words. Each news article would have its words counted to determine the corresponding number of boxes on the layout sheet. He once had a word-counting competition with journalist Nguyen Huu Phach. “We competed to see who could count faster. Phach, being more experienced, counted 2, 4, 6… while I counted sequentially 1, 2, 3… and lost. We both laughed. This illustrates how manual word counting was meticulous and time-consuming,” he said.

After careful planning, the graphic designer must arrange the text on the layout sheet like a real newspaper page: which news item goes at the top, which article at the bottom, the main headline, subheadings, and the size of the text depending on the newspaper's requirements and the value of the content. Because the calculations are relatively precise, there are rarely any instances of extra or missing text. If there are, the person in charge will have to cut or add content promptly.

Once completed, the mock-up will be sent to the printing house.

Typographic printing, hand-typesetting

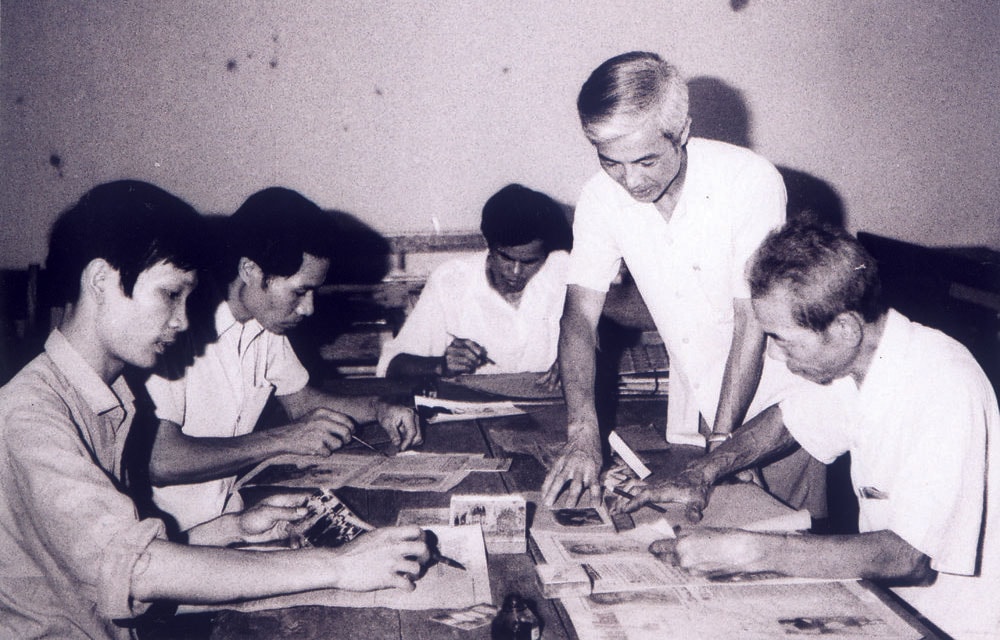

During the 1960s, 70s, and even up to the 80s, most newspapers still used typographic printing technology, arranging types by hand.

Mr. Le Khac Duong, former Head of Administration and Management Department of Hai Duong Newspaper, who was once a worker at Hai Hung Printing Enterprise (in 1985), still vividly remembers that every time they received the layout from the editorial office, the printing house would be bustling with a sense of urgency, with everyone prioritizing the political task of publishing the newspaper the next day.

"We had to bring our own meals to work whenever we had time, and even stay up all night to complete the task on time," Mr. Duong said.

Dozens of people were tasked with assembling the letters. These were small, cast-in-place lead letters (the same size as newspaper print) with all the letters of the alphabet: a, b, c… Each letter was placed in a separate tray. For example, to assemble the word "Ba" (Three), the workers had to pick up two separate letters to combine: B and a, and of course, they had to combine them in reverse so that when printed on paper it would form the word "Ba". The same applied to other letters. When it came to punctuation marks like periods, exclamation points, question marks, commas, parentheses, etc., the workers would pick up those marks and place them in place.

The process of arranging the typesetter in reverse, like a matrix, requires keen eyesight, speed, and experience. The typesetters work sequentially, from the headline and body text to the end of each news article, to form each page of the newspaper. Next, they roll ink over the typefaces and then place a thin piece of paper over them. The result is called a proof, used for reading and proofreading.

Due to outdated technology, typesetting was time-consuming and labor-intensive, requiring close coordination between the editorial office and the printing house. To ensure timely delivery, the editorial office would typically send the first two pages to the printing house about a day before publication for typesetting. The outer pages would then await news articles and other current events.

Back then, photographs had to be printed using zinc plates, while paintings were woodblock prints. As for the photo processing, photojournalists had to travel all the way to Hanoi . Later, the zinc plate printing process was carried out at the Hai Hung Printing Factory, so the photojournalists from our newspaper no longer had to go to Hanoi.

With all preparations complete, the metal zinc plates are combined with the lead type on the printing plate, and the printing press is assembled to print the newspaper.

Once printing is complete, the typesetters carefully remove each typeface and place it back into its correct position in the tray, ready for reuse in the next print run. This process is commonly referred to in the industry as "arranging, correcting, and discarding" (meaning arranging, correcting, and returning the typeface to its original position).

In 1991, Hai Hung newspaper switched from letterpress printing to offset printing.

In 2011, Hai Duong newspaper abandoned manual design and layout on paper layouts, switching to computer-based work. Printing houses also gradually adopted modern prepress technology, "Computer-to-plate" (CTP), eliminating the intermediate film step, shortening printing time, reducing labor, and improving print quality.

Source: https://baohaiduong.vn/thiet-design-in-bao-thoi-bao-cap-413826.html

Comment (0)