Established in early 2024, Cam Pha High-Tech Shrimp Farming Cooperative with a high-tech white-leg shrimp farming model supplies the market. Mr. Dang Ba Manh, Chairman of the Board of Directors and Director of the Cooperative said: We invested 150 billion VND in infrastructure such as greenhouses, machinery, electrical systems... With an area of 8 hectares including 12 ponds (each pond has an area of 1,000m2 ), of which 6 ponds serve water treatment and water storage for shrimp farming.

The high-tech white-leg shrimp farming at the cooperative is divided into 3 stages. In stage 1 (about the first 25 days), the shrimp are raised directly in the greenhouse according to a strict care process for the shrimp to develop; in stage 2 (the next 25 days), the shrimp are stimulated with food to grow to maturity; and stage 3 is the harvesting stage, at this stage, the amount of food is maintained, the number of shrimp on the water area is controlled. When the shrimp reach the standard of 25-30 shrimp/kg, the cooperative will harvest and bring them to the market.

Chairman of the Board of Directors and Director of Cam Pha High-Tech Shrimp Farming Cooperative Dang Ba Manh shared: In each pond, we have an identification code, a specialized roof system to regulate temperature and weather, adjust the light, the pond has a fan and bottom oxygen system, a specialized disease control department... All of the above systems apply the most advanced technology in white-leg shrimp farming today. At the same time, the Cooperative has also equipped with microscopes, and engineers to monitor salinity and check the quality of algae every day. To ensure the shrimp develop at the best level.

Engineer Huynh Kim, in charge of technical supervision at the ponds of the Cam Pha high-tech shrimp farming cooperative, said: Every day, we take water samples from each pond to measure the algae level to see if the algae is good or bad. When the amount of algae grows abnormally, we will adjust the salinity and water volume to suit the shrimp's growth.

The cooperative's high-tech shrimp farming model yields 20 times higher than conventional farming (extensive farming). Copper Timely help reduce the risk of disease; good control of antibiotic residues in shrimp.

Currently, Cam Pha High-Tech Shrimp Cooperative supplies 450-500 tons of white-leg shrimp to the market per year; on average, the cooperative supplies about 45 tons of shrimp per month, bringing in a revenue of 10 billion VND. The Cam Pha High-Tech Shrimp Cooperative's shrimp farming model is considered the most advanced in Vietnam today.

The cooperative also has a traceability code to facilitate export. In the immediate future, the cooperative's consumption source is mainly the domestic market. In the coming time, the cooperative will expand its scale to 120 hectares of white-leg shrimp farming to meet export demand.

According to Mr. Nguyen Ba Manh, the cooperative's high-tech white-leg shrimp farming is a common trend today. Applying digital technology to the farming process will minimize the risk of disease; evaluate the quality of export services, especially for demanding markets. The potential for white-leg shrimp development is still very large. The cooperative is confident in this shrimp farming model because it is sustainable, brings high economic efficiency, and creates jobs and income for workers.

Source: https://baoquangninh.vn/applying-cong-nghe-vao-nuoi-tom-cho-nang-suat-cao-3354229.html

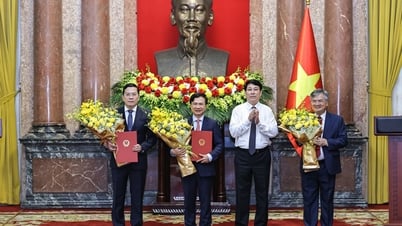

![[Photo] President Luong Cuong presents the decision to appoint Deputy Head of the Office of the President](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/501f8ee192f3476ab9f7579c57b423ad)

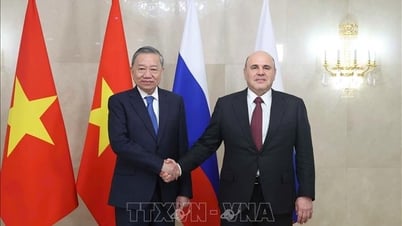

![[Photo] General Secretary To Lam begins official visit to Russia and attends the 80th Anniversary of Victory over Fascism](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/5d2566d7f67d4a1e9b88bc677831ec9d)

![[Photo] Prime Minister Pham Minh Chinh meets with the Policy Advisory Council on Private Economic Development](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/387da60b85cc489ab2aed8442fc3b14a)

![[Photo] National Assembly Chairman Tran Thanh Man chairs the meeting of the Subcommittee on Documents of the First National Assembly Party Congress](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/72b19a73d94a4affab411fd8c87f4f8d)

Comment (0)