|

Many major air conditioner manufacturers in China are joining forces. Photo: China Daily . |

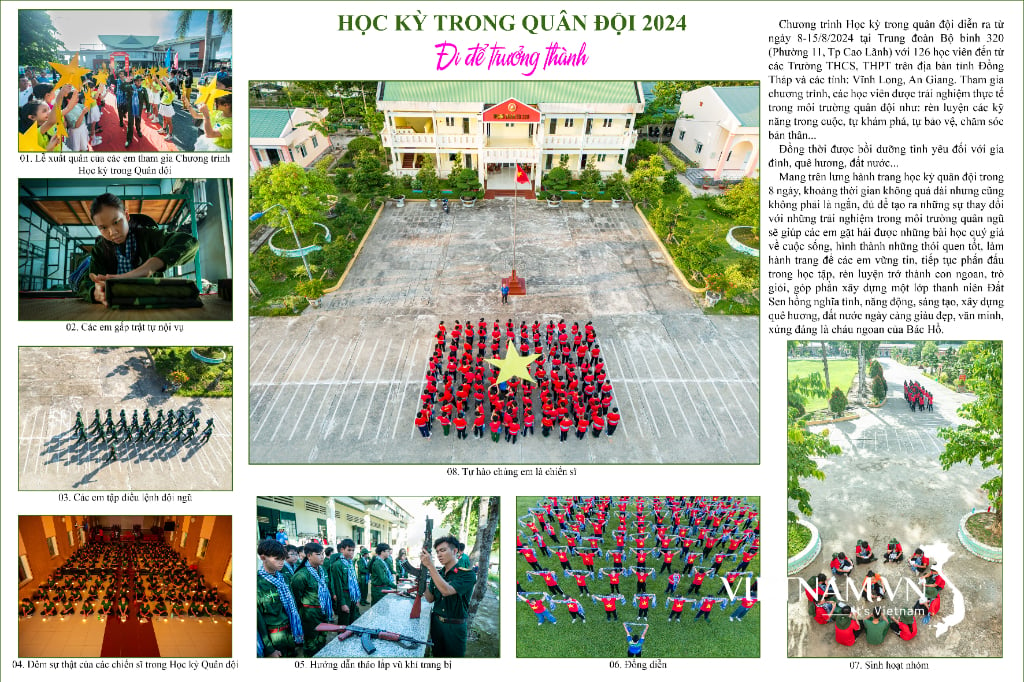

Amidst China's accelerated development of standards related to "aluminum replacing copper" in the air conditioning industry, many large companies have made surprising choices.

On December 12th, several air conditioner manufacturers, including Haier, Midea, and Xiaomi, signed a voluntary agreement pledging not to attack or defame competitors, and to cooperate in promoting the features of air conditioners using aluminum heat exchangers. This move comes as China pushes to finalize technical standards for the trend of replacing traditional materials.

It's uncommon for businesses in the same industry to openly collaborate, especially in the home appliance sector, which is known for its fierce competition in terms of price and technology.

The main reasons cited by businesses for the trend of replacing copper with aluminum revolve around two factors: cost and supply chain security. According to 2023 data, the air conditioning industry in China alone consumed approximately 1.723 million tons of copper, accounting for 10.7% of the country's total copper consumption. Notably, the majority of this copper is imported, making it difficult for businesses to control price fluctuations when the international market is unstable.

Meanwhile, China currently accounts for approximately 60% of global electrolytic aluminum production. Abundant domestic supply gives aluminum a price advantage and long-term stability. Reducing copper usage helps businesses lower production costs and mitigate risks from raw material market fluctuations.

|

The replacement of air conditioning materials raises questions about durability. Photo: Caixin Global . |

However, the change in materials has also raised concerns about performance and durability. In response to these concerns, businesses say they will redesign the structure, manufacturing processes, and energy efficiency standards to meet national requirements.

Technically, copper is considered to have better thermal conductivity than aluminum, and its welding and machining processes have been proven over decades. This is also why many long-standing brands continue to rely on this material, ensuring durability and a long-term user experience.

However, observers believe that technological advancements may gradually narrow the gap between the two materials. New Chinese standards also demand higher standards for overall design and manufacturing processes.

Source: https://znews.vn/dong-thai-la-cua-nganh-dieu-hoa-trung-quoc-post1611170.html

![[Photo] Prime Minister Pham Minh Chinh attends the Conference summarizing and implementing tasks of the judicial sector.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F13%2F1765616082148_dsc-5565-jpg.webp&w=3840&q=75)

Comment (0)