For decades, underground mining units in the Coal Industry have maintained the traditional shift handover method. Accordingly, the foreman or technical officer directly disseminates tasks to workers, based on the production plan and actual situation. Workers will gather at the shift handover house, listen to the work assignment, then sign the logbook. All changes, adjustments, and arising during the work process are also recorded manually. However, this method reveals many limitations, first of all, it is manual and time-consuming.

"A production shift at the Kiln Transport Workshop 2 (Uong Bi Coal Company - TKV) has about 120 workers, divided into many small teams. Previously, the workshop commander had to come to the shift handover house an hour early to write shift orders in a paper book, then spend dozens of minutes taking attendance, reading plans, assigning tasks and taking notes. Many times, just checking the number of workers present, determining who went to the furnace, who worked on the ground took 2.5-3 hours/shift, affecting the production pace" - Mr. Bui Van Cuong, Manager of Kiln Transport Workshop 2, Uong Bi Coal Company said.

In addition, the accuracy of the shift handover is not absolutely guaranteed. When depending on paper books and human memory, mistakes, omissions or lack of information communication are inevitable. This not only causes production interruptions but also poses a potential risk of safety. Faced with the increasingly high demands of underground production, TKV and its units need a new, more modern, faster and more accurate step.

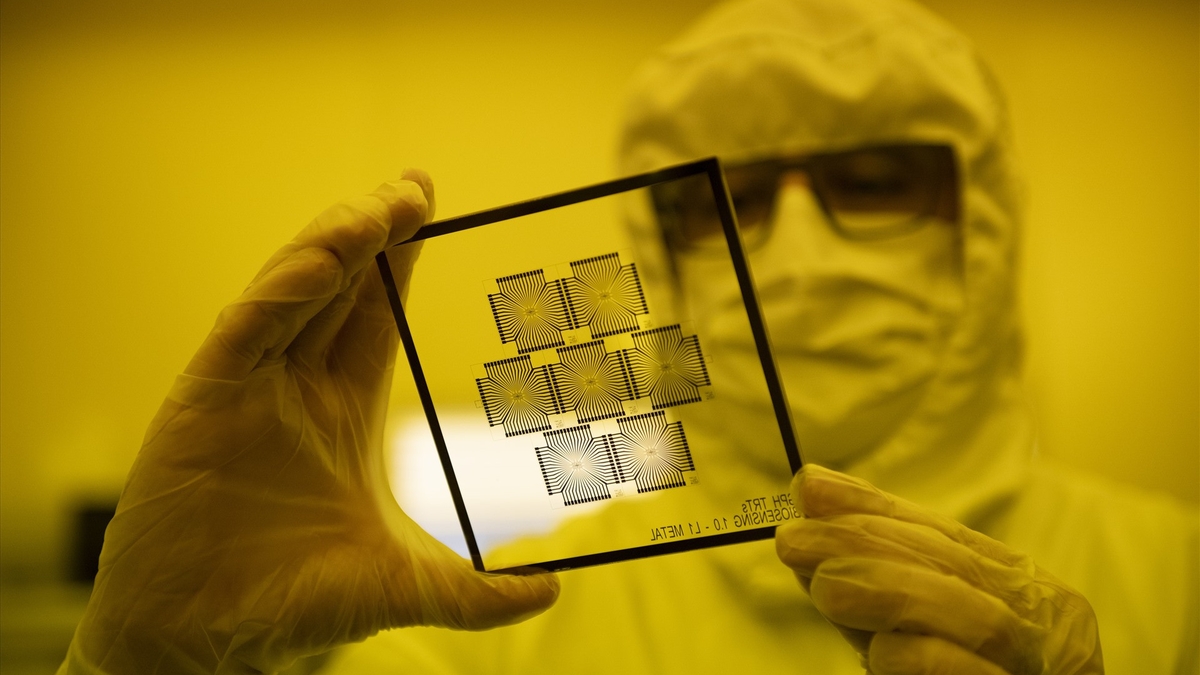

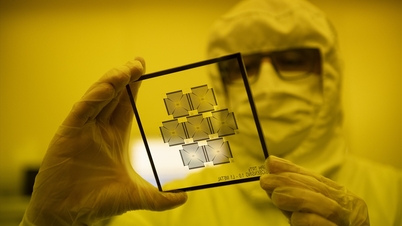

2019 marked a turning point when Uong Bi Coal Company became the first underground coal mining unit in TKV to apply electronic shift handover using online command software combined with facial and fingerprint recognition. This is one of the powerful innovative solutions, aiming at the goal of modernizing management, improving productivity and labor safety.

After 5 years of implementation, the benefits that the electronic shift handover method brings to Uong Bi Coal are very clear. Each production shift saves hours of shift handover time, which means more time to perform work directly in the furnace. The daily orders are updated on the system, information about equipment status, production conditions, incidents in the previous shift, etc. are updated and transmitted accurately and promptly. Workers in the furnace have a firm grasp of their tasks and safety precautions. This helps production direction to be more flexible, close and effective.

Mr. Do Anh, Deputy Director of the Company, said: Up to now, 100% of the workshops in Uong Bi Coal Company have applied electronic shift handover, not only stopping at the scope of one workshop, but also connecting with other areas in the whole company such as the canteen, light house, labor protection distribution house... The centralized data system helps the company easily manage overall production, while serving analysis and forecasting for long-term planning.

Vang Danh Coal Joint Stock Company has also become a bright spot in applying electronic shift handover using software. Based on the experience inherited from Uong Bi, Vang Danh Coal has deployed it synchronously in many production workshops.

Here, the shift handover no longer involves the foreman reading lengthy orders and workers jostling to sign the logbook as before. Instead, all information is updated quickly on the software. Workers only need to scan their fingerprints or faces to complete the roll call and clearly understand their tasks. Changes in the production plan are also updated instantly, minimizing confusion or having to re-communicate from the furnace to the worksite.

Actual results show that many workshops of Vang Danh Coal have increased productivity and output thanks to electronic shift handover. In 2024, the company achieved an output of nearly 3.8 million tons of raw coal, labor productivity increased by more than 8% compared to 2019. Shift handover software has contributed significantly to this result.

More importantly, the electronic shift handover has contributed to forming a modern, professional working style for the mining team. From being familiar with paper and pen books, they are now proficient in operating the system, accessing new technology, raising awareness of safety and labor discipline. This is the foundation for Than Vang Danh, as well as many other units in TKV, to aim for the goal of smart production in the digital transformation era.

From the shift handover software platform, many mines have been and are continuing to deploy other management software such as material software, accounting software, production management... These are signals showing that TKV's underground mining units are ready to enter a new phase, building a modern, smart mine model, suitable for the requirements of sustainable development in the future.

Source: https://baoquangninh.vn/nhan-rong-mo-hinh-giao-ca-dien-tu-trong-cac-don-vi-nganh-than-3376182.html

![[Photo] Da Nang: Hundreds of people join hands to clean up a vital tourist route after storm No. 13](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/07/1762491638903_image-3-1353-jpg.webp)

Comment (0)