Essential requirement

Ms. Tran Do Quyen, Deputy Director of the Department of Trade Defense ( Ministry of Industry and Trade ), said that the world's geopolitical context continues to evolve unpredictably, along with the trend of slowing global economic and trade growth, putting a lot of pressure on export enterprises. Major markets are increasingly tightening import standards, focusing on issues of sustainable development, consumer safety and environmental protection. To take advantage of opportunities, enterprises need to proactively innovate and build long-term strategies. Investing in technology, human resources and taking advantage of free trade agreements (FTAs) to expand the market is essential. Enterprises also need to focus on applying digital technology to increase competitiveness and professionalism, as well as deploying contingency plans to minimize risks from market fluctuations.

Mr. Alexander Christopher Falter, General Director of Ecco Vietnam Co., Ltd., said that in 2025 the company plans to expand the factory with modern technologies and production processes. The company is currently making efforts to train human resources to meet the needs of production expansion. Currently, Ecco is also pioneering the transition to green, sustainable ecological industry in Binh Duong. In the immediate future, the company will use solar power at the factory, then reuse rainwater and equip electric charging stations for some electric vehicles.

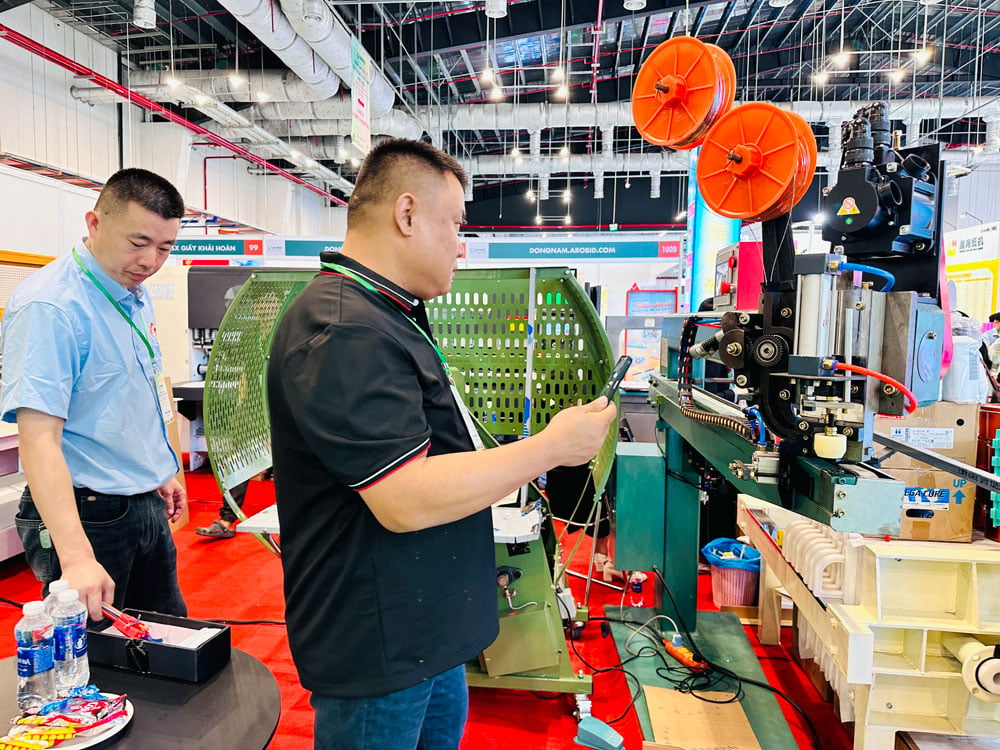

According to the leader of Dong A Steel Corporation, modern technology is becoming a decisive factor in improving productivity, product quality as well as the competitiveness of enterprises, especially in the context of the 4.0 industrial revolution and the current strong and extensive international integration process. With the commitment to "Green production - green products", the company is constantly striving to become a pioneer in sustainable development. The ISO 9001:2015 quality management system plays a guiding role, helping the company maintain product stability and consistency, while ISO 50001:2018 supports optimizing energy management, minimizing waste and improving operational efficiency.

To affirm its responsibility to the environment, Dong A Steel Joint Stock Company has achieved important certifications such as ISO 14001 on environmental management, ISO 14067:2018 for measuring the carbon footprint of products, ISO 14064-1:2018 for greenhouse gas inventory; at the same time, the ISO/IEC 17025 laboratory management system ensures that all testing and quality assessments are of the highest accuracy. Currently, Dong A Steel also invests heavily in modern technology, especially the installation of a solar power system on the factory roof at Thu Dau Mot City Branch, helping to exploit renewable energy sources and significantly reduce carbon emissions during the production process.

According to Mr. Luu Tri, Vice President of Binh Duong Electromechanical Association, the Government is promoting a strategy of self-reliance in construction technology, limiting the import of equipment and materials, and encouraging enterprises to invest in research and development. However, the big challenge for enterprises is that the application of new technology requires significant capital, along with perseverance in the process of research, testing and implementation.

Increase links

Regarding funding, Mr. Nguyen Quang Vu, Chairman of the Binh Duong Leather and Footwear Association, said that in order to deploy new technology in the context of the 4.0 technology revolution, Vietnamese enterprises face many difficulties in terms of financial capacity and production infrastructure. However, Mr. Nguyen Quang Vu said that the Ministry of Science and Technology has funds to support enterprises, such as the Technology Innovation Fund, which can support 30-40% of costs related to technology investment. This is one of the policies that creates favorable conditions for enterprises to have the opportunity to upgrade production technology to enhance competitiveness.

Currently, there are many high-tech foreign direct investment (FDI) enterprises in the province. However, the linkage of technology development with FDI enterprises requires leading birds to promote the role of "leader". Mr. Nguyen Trong Luat, General Director of Cicor Vietnam Co., Ltd., said that the company recently coordinated with two strategic partners to organize a workshop with the theme "Smart Injection Molding and Digital Transformation in Industry". The event attracted more than 100 guests, including directors, department heads, and engineers from more than 40 enterprises in the fields of plastic injection, electronics, and commerce. Here, the speakers shared about the development journey of Cicor Group, the digital transformation strategies that are being effectively implemented at Cicor Vietnam.

The event not only provided practical knowledge about digital transformation at optimal cost, but also served as a bridge for businesses in the industry to meet, exchange and seek cooperation opportunities. The positive feedback from the delegates attending the workshop is a clear demonstration of the value of the program and the value of the in-depth workshops.

Ms. Huynh Dinh Thai Linh, President of Binh Duong Logistics Association, said that the association has been actively promoting connections to support businesses in developing smart logistics systems, combining modern warehouses, artificial intelligence, and big data technology to optimize transportation and reduce distribution costs. The association recommends that businesses apply flexible warehouse solutions, green logistics, and diversify transportation methods to reduce costs and optimize transportation time. |

TIEU MY - ANH TUAN

Source: https://baobinhduong.vn/phat-trien-cong-nghe-nang-tam-san-xuat-a347910.html

![[Photo] General Secretary To Lam receives Chief of the Central Office of the Lao People's Revolutionary Party](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/140435f4b39d4599a3d17975dfb444c5)

![[Photo] National Conference "100 years of Vietnamese Revolutionary Press accompanying the glorious cause of the Party and the nation"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/1cf6cd5c8a934ebfa347028dcb08358c)

![[Photo] Journalists moved to tears at the Memorial Service for the soldiers who died in Gac Ma](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/9454613a55c54c16bf8c0efa51883456)

Comment (0)