Steady growth but still have to import raw materials

According to the Ministry of Industry and Trade , although the plastics industry is one of the industries with high growth, it is still only known as a technical economic sector of plastic processing. In particular, the plastics industry is still not self-sufficient in input materials. Specifically, 70 - 75% of input materials and accessories must be imported because the current domestic supply can only meet about 1 million tons. In particular, there is a lack of supply of recycled plastic materials and the supporting industry for the plastics industry is not yet developed. Enterprises are not self-sufficient in input materials; the cost of raw materials accounts for the highest proportion in the cost structure of the industry. This situation leads to the fact that plastics enterprises have to maintain large inventories of raw materials to ensure uninterrupted production and business activities.

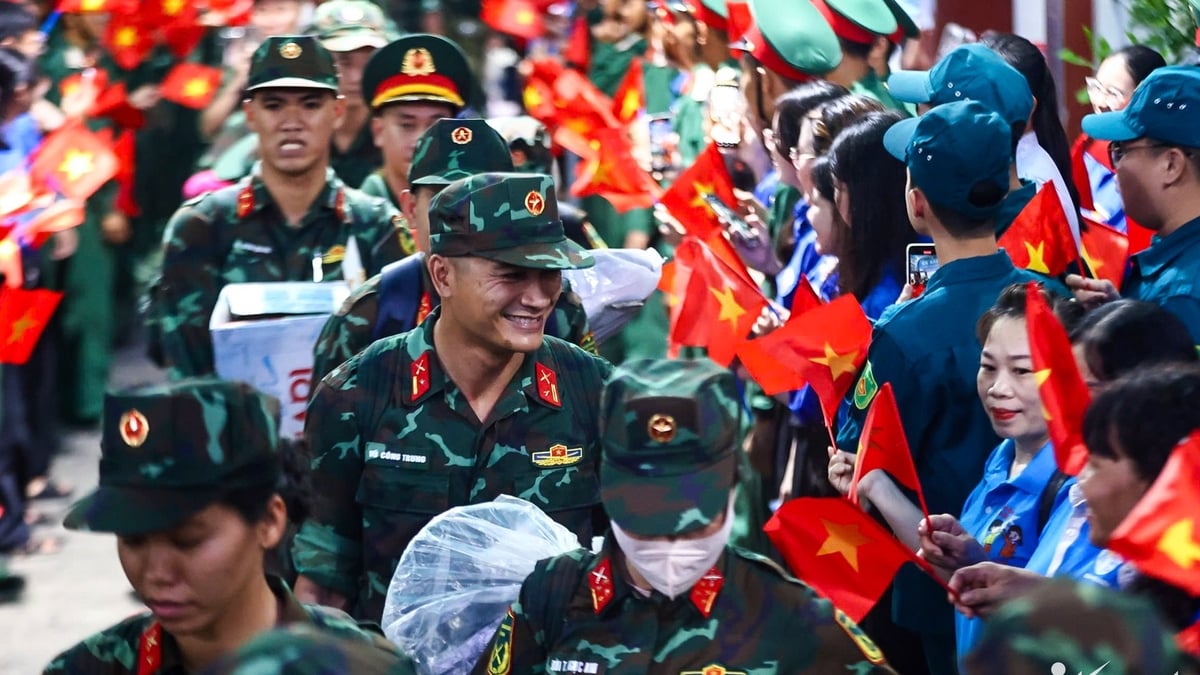

|

| Lack of raw material supply is one of the barriers hindering the development of the plastics industry. Photo: VPA |

According to a report by the Vietnam Plastics Association (VPA), the plastics industry has nearly 4,000 enterprises nationwide; of which, 90% are small and medium-sized enterprises, mainly concentrated in the Southern region.

Vietnamese plastic enterprises have been producing a full range of plastic products for domestic consumption and export markets; in which, Vietnamese plastic products have been exported to more than 160 countries around the world and are present in many demanding markets such as the US, Germany, France, UK, Italy, Netherlands, Spain, Japan, etc. Plastic product exports in the first 6 months of 2024 increased sharply, reaching over 3.15 billion USD, an increase of over 32% over the same period in 2023.

According to VPA, the growth rate of Vietnam’s plastic industry in the past 5 years has always been at a double-digit rate of 12-15%/year. Domestic raw materials can meet more than 30% of domestic market demand, while the remaining 70% is imported from many countries and territories.

Currently, each year the plastic industry needs about 4.5-5 million tons of input materials such as PE, PP, PS, PVC... not to mention hundreds of different auxiliary chemicals, while domestic capacity can only meet about 1 million tons of raw materials, chemicals and additives for the needs of the Vietnamese plastic industry.

This situation has led to plastic companies having to maintain large inventories of raw materials to ensure uninterrupted production and business operations. This has resulted in increased financial costs, plus risks of changes in exchange rates and world oil prices. This limitation is a common feature of the entire Vietnamese plastics industry and is unlikely to change in the next few years.

Increasing capacity of plastic raw material production project

Another limitation mentioned by the Ministry of Industry and Trade is that small and medium-sized enterprises (accounting for more than 90% of the total 2,000 plastic enterprises) often pay little attention to investing in modern technology and machinery, so Vietnamese plastic products are mostly in the low-end segment. Only a few large-scale enterprises are willing to invest in depth and have products that meet the increasing needs and tastes of consumers, making the competitiveness of Vietnamese plastic products in the market not high, especially household plastic products.

According to VPA, plastics is a key industry that is assessed to have much potential and many opportunities for domestic enterprises. Therefore, to compete better, domestic manufacturing enterprises must consider seriously investing in technology, especially energy-saving and environmentally-friendly production technologies.

VPA recommends that authorities should create opportunities and increase investment capacity in companies and projects producing raw materials for the plastic industry. Furthermore, plastic enterprises should also focus on finding and developing domestic raw material sources to avoid risks affecting import and export activities. " Domestic plastic enterprises need to gradually expand factories, prepare raw material sources, promote products with high added value... This is considered one of the solutions for plastic enterprises to affirm their advantages " - VPA proposed solutions and commented that, with the general trend of the world in developing a circular economy as well as in Vietnam, the Government is building a domestic plastic recycling industry to create a source of recycled plastic materials. That will contribute to increasing investment in new machinery and technology to serve market demand, creating opportunities for suppliers of new machinery and raw materials in the future.

Mr. Ho Duc Lam - Chairman of VPA also proposed solutions, specifically the need to increase research and development. The world and Vietnamese plastics industries will increase investment in research and development of new plastic technology, in order to create high-quality products, save raw materials and energy, and minimize negative impacts on the environment.

The Ministry of Industry and Trade also believes that domestic plastic enterprises need to gradually expand factories, prepare raw material sources, promote products with high added value, etc. This is considered one of the solutions for plastic enterprises to affirm their advantages.

Realizing the potential and room for development, in recent years, many plastic enterprises have proactively invested in machinery and equipment and technology to increase production output to meet the increasing demand of the market.

The representative of An Tien Industries Joint Stock Company (HII) said that in the past 5 years, witnessing the great demand for raw materials in both domestic and foreign markets, the company has proactively restructured its investment, equipping modern production lines worth tens of billions of VND. In particular, the unit has just invested in a new grinding machine system to optimize production and increase output, while improving product quality and diversifying high-end product lines.

In addition, many units operating in the plastics industry and related industries have identified sustainable development as the guiding principle in all business operations. These units, while focusing on investing in building recycling plants, are also actively participating in contributing initiatives related to the "green production path".

Source: https://congthuong.vn/chua-tu-chu-duoc-nguon-nguyen-lieu-doanh-nghiep-nganh-nhua-con-nhieu-noi-lo-339066.html

Comment (0)