Vietnam Electricity Group (EVN) has just announced the adjustment of electricity prices from May 10, 2025. The average retail electricity price after adjustment is VND 2,204.0655/kWh (excluding value added tax). According to EVN's calculations, for service business customers, the average increase per customer is VND 332,000/month; for manufacturing customers, after the price adjustment, each customer will pay an average additional VND 677,000/month.

This is the fourth consecutive increase in electricity prices since 2023. Previously, in 2023, EVN increased electricity prices twice by 3% and 4.5% respectively; on November 10, 2024, EVN continued to adjust electricity prices up by another 4.8%.

Thus, from 2023 to now, electricity prices have increased by more than 17%, causing disadvantages for businesses in the context of facing many difficulties and challenges.

Nam Ha Tinh Seafood Import-Export Joint Stock Company (Ky Anh Town) specializes in exporting processed shrimp and squid to the Japanese market. Operating in the seafood processing industry, the company consumes a large amount of electricity because the processing process must go through the stages of cooling, storing raw materials, cleaning tools...

Mr. Pham Van Tuc - Deputy CEO of Nam Ha Tinh Seafood Import-Export Joint Stock Company shared: “Electricity accounts for about 15% of production costs, so the increase in electricity prices is a big burden for businesses. Every month, the company spends more than 250 million VND on electricity, now the price has increased by 4.8%, meaning that each month it incurs more than 12 million VND for this cost. In the past, although input materials were scarce and prices increased, the company still tried to reduce production costs instead of increasing product prices to compete in the market. Now that electricity prices have increased, the unit must rebalance its production and business plans and implement solutions to reduce production costs.”

It is known that Nam Ha Tinh Seafood Import-Export Joint Stock Company has just invested tens of billions of VND to buy a new freezing system with higher capacity, repair the factory to suit its function, and avoid power loss. In addition, the company continues to apply energy-saving solutions such as: recovering heat from the refrigeration system to produce hot water; using cold water directly instead of flake ice and water, avoiding the use of high-capacity electricity-consuming machines during peak hours. The company is also researching and calculating the installation of rooftop solar power to proactively source electricity.

Vinatex Hong Linh Joint Stock Company (Hong Linh Town) specializes in producing and exporting yarn to markets such as Egypt, Japan, Bangladesh, etc. With modern machinery lines, large capacity, and high automation, each month, the enterprise spends more than 2 billion VND on electricity. The 4.8% increase in electricity prices means that each month, the enterprise has to pay more than 100 million VND more for electricity. Although production and business activities have shown signs of recovery compared to the previous period, the yarn industry still faces many challenges. Accordingly, the increased cost of imported raw materials, the increase in USD exchange rate, etc. have greatly affected the operation of the enterprise. In addition, the fluctuation in electricity prices for 3 consecutive years (from 2023 - 2025) has put more pressure on the enterprise.

To reduce costs, the company continues to review and invest in replacing old, energy-consuming machines; focuses on maintaining equipment and machines to avoid power loss; develops appropriate production plans, prioritizing production during off-peak hours to save costs. In addition, the company participates in adjusting the electricity load (DR) according to EVN's recommendations, limiting production during peak hours, arranging to move many tasks to other time frames; avoiding operating all machines at the same time; allocating production lines and equipment to operate in rotation...

TAAD Ha Tinh Investment and Trading Production Joint Stock Company (Ha Tinh City) has a scale of more than 10 sewing lines, specializing in sewing garment products for export to Japan. Each month, the unit consumes over 150 million VND in electricity bills. According to the leader of TAAD Ha Tinh Investment and Trading Production Joint Stock Company: According to calculations, with this increase in electricity prices, each month, the business will have to pay more than 7.5 million VND in electricity bills. Sewing with low profits, so the arising costs will affect the business's revenue and the salary of workers.

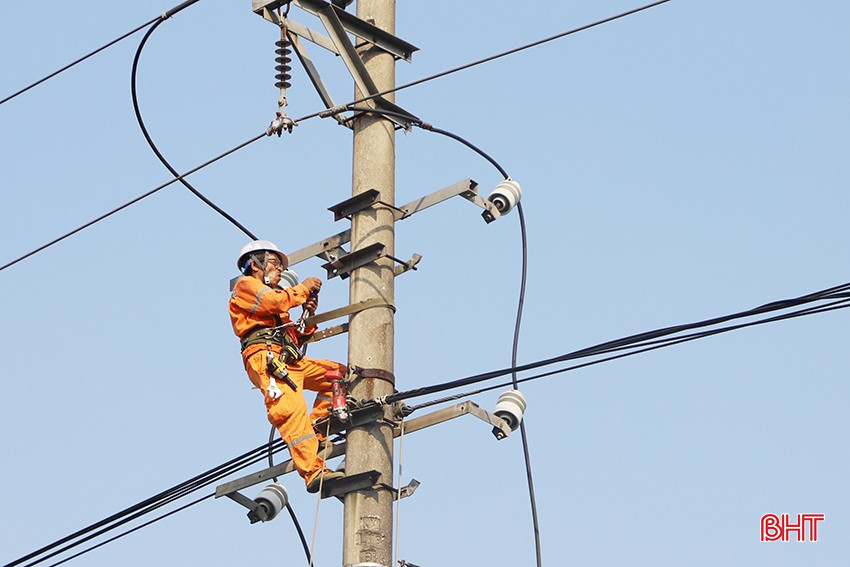

For businesses with their own transformer stations, the electricity industry recommends regular maintenance and servicing according to regulations.

TAAD Ha Tinh Investment and Trading Production Joint Stock Company has 1 transformer station (capacity 400 KVA). To operate safely and stably, avoiding power loss, the company has coordinated with Ha Tinh City Electricity to perform maintenance and repair work according to regulations. In addition, the unit prioritizes the use of boilers with reasonable capacity to avoid underload. With a lighting system and large factory space, the company has invested in high-efficiency light bulbs, arranged light bulbs and switches reasonably to ensure lighting needs and save energy, and used sewing machines with appropriate capacity...

At Tran Chau Construction Investment Company Limited (Bac Cam Xuyen Industrial Park), with the characteristics of the construction materials manufacturing industry, consuming a large amount of electricity, in 2020, the company installed a solar power system to serve production, thereby significantly reducing electricity costs. However, on average, the company still has to spend about 60 million VND per month. Ms. Tran Thi Thanh - chief accountant of the company said: "In the context of many input materials such as stone, sand, iron, cement, and auxiliary materials increasing in price, the 4.8% increase in electricity price from May 10 is also an additional burden for the company. To minimize this cost, the company continues to arrange reasonable production personnel, operate production workshops and equipment at different hours, avoiding peak hours".

Mr. Phan Van Anh - Head of Business Department, Ha Tinh Electricity Company recommends: To save electricity, businesses need to optimize the electrical system, regularly clean and maintain machinery and equipment, replace low-efficiency equipment and old technology; strengthen internal electricity saving, build awareness of electricity saving in businesses.

The electricity industry encourages customers to participate in the load shifting (DR) program, which means reducing electricity use during peak hours, or shifting electricity use from peak hours to off-peak hours, contributing to ensuring electricity supply, improving electricity quality and reliability of electricity supply. At the same time, using renewable energy, installing and integrating renewable energy sources such as self-produced and self-consumed rooftop solar power systems into the internal energy system; having solutions to take advantage of natural light during work, replacing electric bulbs.

Source: https://baohatinh.vn/doanh-nghiep-ha-tinh-kich-hoat-cac-giai-phap-ung-pho-gia-dien-tang-post287775.html

![[Photo] Welcoming ceremony for Hungarian President Sulyok Tamas and his wife on an official visit to Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/28/7956bacf4a3e4bde8326cb8f72a3b26c)

![[Photo] President Luong Cuong holds talks with Hungarian President Sulyok Tamás](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/28/0f603676be6444aa9f52d4bd32582b4d)

![[Photo] Hungarian President and his wife take a walk and enjoy the view of Hoan Kiem Lake](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/28/b9c83fbe6d5849a4805f986af8d33f39)

![[Photo] Hungarian President begins official visit to Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/27/ab75a654c6934572a4f1a566ac63ce82)

![[Case Study] VIMC – 30-year journey of overcoming waves and reaching far](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/28/ac45a93a62884eec85471e6c89ef521a)

Comment (0)