On October 31, Samsung SDI announced that it had signed a three-way cooperation agreement with BMW and Solid Power to develop and test solid-state batteries, aiming to equip BMW's next-generation test vehicle. Under the agreement, Solid Power will supply solid electrolytes, Samsung SDI will produce battery cells with higher energy density and safety, and BMW will develop battery modules and packs for real-world testing. Samsung SDI aims to mass-produce solid-state batteries by 2027.

Tripartite alliances and their role in the value chain

The collaboration between Samsung SDI (cell manufacturing), BMW (system integration) and Solid Power (solid electrolyte material supply) brings together three key links in the battery value chain. The immediate goal is to create test battery packs that will operate in next-generation BMW vehicles to evaluate durability, safety and performance under real-world conditions.

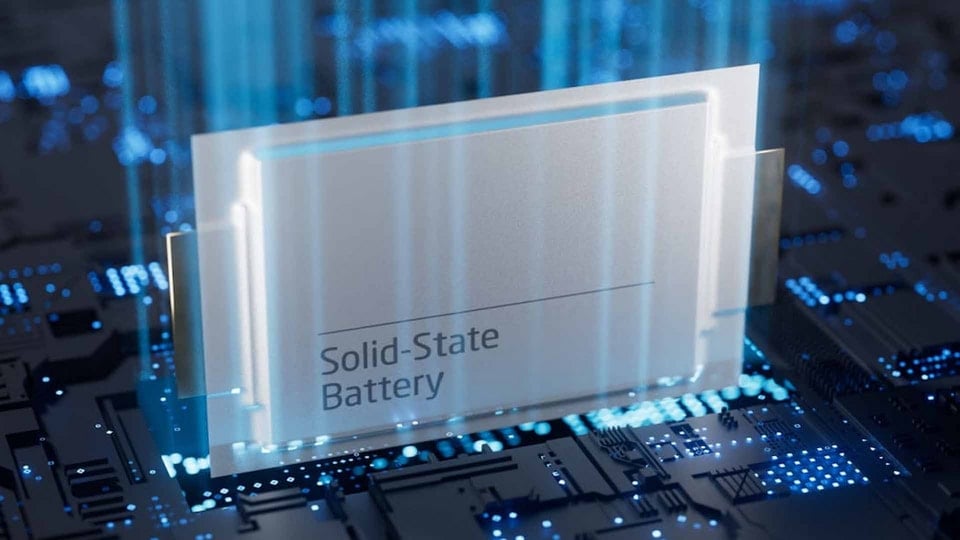

Solid-state batteries and their implications for electric vehicles

Unlike traditional lithium-ion batteries that use liquid electrolytes, solid-state batteries use solid materials, which significantly reduces the risk of explosion due to electrolyte leakage. This structure also reduces the need for individual cell sealing, which helps optimize system mass. With high safety and the potential for greater energy density, solid-state batteries are considered the “game changer” of the next generation of batteries.

Cost barriers and production problems

The biggest challenge at present is cost. According to analysis, the cost of manufacturing solid-state batteries is 3–5 times higher than that of lithium-ion batteries using liquid electrolyte. The infrastructure requirements are also more expensive, estimated to be 10–20 times higher. Therefore, to date, no commercial electric vehicle equipped with solid-state batteries has been truly launched on the market. The Samsung SDI – BMW – Solid Power alliance aims to combine technology and scale to narrow the cost gap and shorten the time to commercialization.

Samsung SDI Progress and Application Plan

Among the three major battery manufacturers in Korea, Samsung SDI is considered to have the fastest development speed of solid-state batteries. In 2023, the company will build a solid-state battery pilot line at the SDI Suwon Research Institute, start producing sample products from the end of 2023 and is currently testing at many enterprises. In addition to the electric vehicle sector, Samsung SDI plans to expand into markets requiring high energy density such as robots and has begun negotiations with potential customers to prepare for mass production.

Statements from stakeholders

“Battery technology capabilities directly lead to EV innovation. We will continue to collaborate closely with global partners to lead the commercialization of solid-state batteries,” said Go Joo-young, Vice President and Head of the ASB Commercialization Acceleration Team at Samsung SDI.

“With Samsung SDI’s involvement, we can further accelerate the development of next-generation battery cell technology,” said Martin Schuster, Head of Battery Cells at BMW Group. “This global collaboration once again demonstrates BMW’s ultimate goal of providing the most advanced battery technology.”

“We will work closely with automakers and leading global battery companies to commercialize solid-state battery technology,” said John Van Scoter, CEO of Solid Power.

Market outlook

The outlook for the solid-state battery industry is positive. The global market size is expected to increase nearly sevenfold in five years, from $148 million this year to $963 million in 2030. The growth drivers are the need to increase the energy density and safety of electric vehicles, and efforts to optimize costs through deep cooperation between businesses in the value chain.

Key milestones and parameters

| Category | Information |

|---|---|

| Cooperation Agreement | Signed on October 31 between Samsung SDI, BMW, Solid Power |

| Roles of the parties | Solid Power: solid electrolyte supply; Samsung SDI: cell production; BMW: module development, battery pack and field testing |

| Production costs | 3–5 times higher than lithium-ion batteries using liquid electrolyte |

| Facility costs | 10–20 times higher than lithium-ion batteries |

| Pilot line | Construction in 2023 at SDI Suwon Research Institute |

| Sample products | Starting from the end of 2023, testing at many businesses |

| Mass production goals | 2027 |

| Market size | 148 million USD (this year) → 963 million USD (2030) |

From a technical and market perspective, if the cost hurdles can be overcome and the manufacturing process can be perfected, solid-state batteries could offer significant advances in energy density and safety for electric vehicles. The collaboration between Samsung SDI, BMW and Solid Power lays the groundwork to accelerate that process, moving the technology from the experimental stage to real-world deployment in the coming years.

Source: https://baonghean.vn/samsung-sdi-bmw-va-solid-power-hop-tac-pin-the-ran-10310425.html

![[Photo] Opening of the 14th Conference of the 13th Party Central Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/05/1762310995216_a5-bnd-5742-5255-jpg.webp)

![[Photo] Panorama of the Patriotic Emulation Congress of Nhan Dan Newspaper for the period 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762252775462_ndo_br_dhthiduayeuncbaond-6125-jpg.webp)

Comment (0)