The furniture industry's export target of $17.5 billion this year is almost impossible to achieve and is likely to reach only $13.5 billion.

After a sharp decline in orders of around 40% in the first half of the year, the furniture industry showed signs of recovery starting in July, with monthly growth of 2-5% compared to the previous month. By October, export turnover reached $1.2 billion, a 5.7% increase compared to September, according to data from the General Department of Customs.

However, overall for the first 10 months, the export value of wood and wood products is estimated at 10.8 billion USD, a decrease of 19.9% compared to the same period in 2022. This is due to weak purchasing power in major markets such as the US and Europe because of unfavorable economic conditions , and a strained real estate market caused by high interest rates.

With less than two months left until the end of the year, the furniture industry's export target of $17.5 billion is almost impossible to achieve. "It is projected that by the end of this year, export turnover could reach $13.5 billion if the situation continues to be favorable (improving) as it is now," said Mr. Nguyen Quoc Khanh, Chairman of the Ho Chi Minh City Handicraft and Wood Processing Association (Hawa), at an event on November 17th.

Even if the target isn't met, achieving $13.5 billion in exports for the whole year would still be a better result than the pre-pandemic period, i.e., from 2020 onwards, and only slightly lower than 2021 and 2022. This was a period when Covid-19 impacted the economy, causing many people to stay home and creating a need to renovate their living spaces or move to a new place.

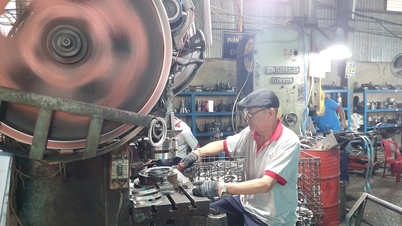

Despite facing difficulties, the wood industry remains a key export sector within the agriculture, forestry, and fisheries group, according to Mr. Khanh. Currently, Vietnam has over 5,000 businesses operating in the wood and furniture industry. Approximately half of export revenue comes from the US market.

An interior design event in Ho Chi Minh City in April 2022. Photo: Viễn Thông

Therefore, when forecasting the situation in 2024, Mr. Nguyen Chanh Phuong, Director of Danh Moc Company and Vice President of Hawa, said that one can look at the prospects of the US market to see positive signs.

Firstly, Colliers' recent "Fall 2023 Retail Report" indicates that nearly 49% of retail chains in the US plan to expand in the next five years. And as of September, retail sales in the country continued to grow even as consumers faced various economic pressures, according to the National Retail Federation. These are promising signs for the furniture retail sector.

Secondly, with the US Federal Reserve (Fed) potentially gradually lowering the benchmark interest rate from the beginning of 2024, mortgage interest rates are likely to fall from the current level of around 8% to 6% by the end of next year, helping to revitalize the real estate market.

"In the US, real estate is a sign of a warming interior design market," Mr. Phuong said. According to him, there are predictions that business will improve from the end of the second quarter of 2024 thanks to lower interest rates.

Thirdly, Vietnamese furniture businesses themselves are proactively seizing opportunities from now until the beginning of next year. In March 2024, this community will focus its efforts on Hawa Expo 2024 - the official representative of the Vietnamese wood industry in the series of Asian Furniture Export Fairs held annually in March.

This is the largest event ever held, taking place simultaneously in three locations (two in Ho Chi Minh City and one in Binh Duong ), bringing together more than 80% of the 700 participating businesses from Vietnam.

According to Mr. Phuong, if trade promotion activities go smoothly, Vietnamese businesses will have the opportunity to secure many orders in April-May 2024, at the same time that the US real estate market is likely to ease due to lower interest rates.

Furthermore, according to Mr. Khanh's observations, there is a trend of businesses gradually shifting from contract manufacturing to ODM (Original Design Manufacturer) production (where the manufacturer designs and manufactures products according to customer orders, rather than following existing designs). This approach will also help create more added value for domestically produced wood products for export in the future.

Telecommunications

Source link

![[Photo] Prime Minister Pham Minh Chinh attends the Conference summarizing and implementing tasks of the judicial sector.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F13%2F1765616082148_dsc-5565-jpg.webp&w=3840&q=75)

Comment (0)