At the workshop “Vietnam’s beverage industry in the new era: Trends, challenges and opportunities” held on the morning of November 7, Associate Professor Dr. Nguyen Van Viet, Chairman of the Vietnam Beer - Alcohol - Beverage Association (VBA), commented that the speed of change in the market is forcing businesses to “transform green faster and apply technology more strongly” if they do not want to fall behind in the context of increasingly fierce competition.

This shift comes not only from global consumption trends, but also from new policies and aspirations for sustainable development within the industry. According to VBA data, the beverage industry contributes about 60,000 billion VND to the budget each year and creates jobs for hundreds of thousands of workers. However, pressure is growing from both consumers and the legal framework.

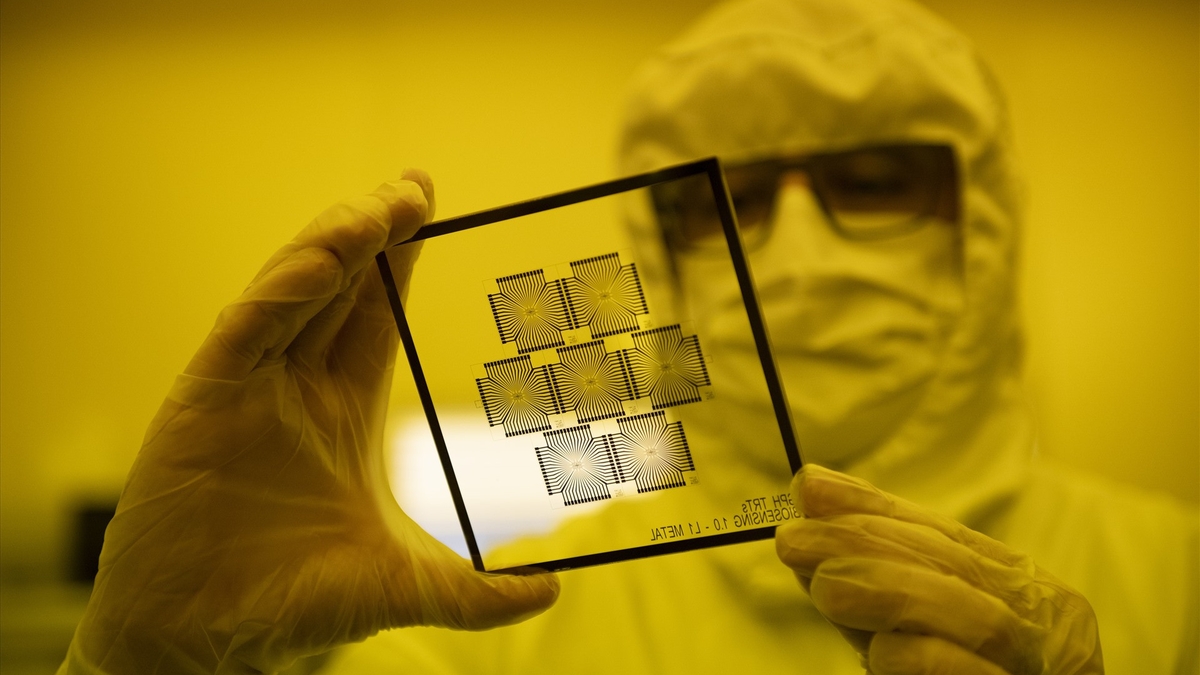

The trend of green consumption and green production was emphasized by VBA at the workshop. Photo: Organizing Committee.

Changing markets: from consumer trends to green technology

From 2027, sugary soft drinks will be subject to a special consumption tax of 8%, increasing to 10% from 2028. Beer and wine will be taxed 5% each year for five consecutive years. Along with that are a series of new regulations on labeling, traceability, recycled packaging and environmental standards. “This pressure will force businesses to invest in technology, restructure production and adapt to green criteria,” Ms. Chu Thi Van Anh, Vice President and General Secretary of VBA, emphasized.

Domestic consumers are increasingly concerned about health, preferring low-sugar, vitamin-enriched, natural and environmentally friendly drinks. This is the foundation for manufacturers to reposition their products, while opening up cooperation opportunities for technology businesses and supporting solutions in the beverage sector.

One of those platforms, mentioned at the workshop, is the advanced membrane filtration system of Suntar Group (Singapore). Mr. Tran Minh Triet, Chief Representative in Vietnam, said that ceramic membrane and spiral membrane technology (RO, NF) helps filter and concentrate the solution without heating, preserving natural flavor, reducing energy consumption and wastewater. The system can process up to 5,000 liters of juice per hour, raising Brix from 12 to 25 degrees, achieving 85% recovery efficiency in the coconut water production process, while maintaining the full nutrients and flavor of the product.

According to Mr. Triet, this is a “true green” solution, both optimizing costs and meeting international standards on food safety and the environment. “Membrane technology helps businesses improve quality, save energy and move closer to a sustainable production model,” he said.

Such technological innovations show that the green transition is not just about raw materials or packaging, but permeates the entire production process, from water treatment, filling, to energy and waste management.

Mr. Tran Minh Triet, Chief Representative of Suntar in Vietnam, shared about technology that helps businesses save costs and reduce emissions. Photo: Organizing Committee.

4 groups of solutions to achieve net zero emissions

Associate Professor Dr. Nguyen Dinh Tho, Deputy Director of the Institute of Strategy and Policy on Agriculture and Environment, said that the beverage industry plays an important role in the process of implementing the commitment to net zero emissions by 2050. To achieve this goal, businesses need to focus on four groups of solutions: saving energy, expanding the use of renewable energy, developing environmentally friendly packaging and managing emissions along the supply chain.

He emphasized that the circular economic model is becoming an inevitable trend when the Law on Environmental Protection, the Decree on Extended Producer Responsibility (EPR) and the revised environmental tax policy will create a legal framework forcing businesses to take action. “Green transformation is no longer a management requirement, but an opportunity to improve competitiveness, attract investment and meet sustainable consumption trends,” he said.

WWF Vietnam expert Bui Tran Trung Hau added that electrification of production lines and heat recovery in breweries and beverage factories can significantly reduce greenhouse gas emissions. When combining electrochemical technology with artificial intelligence, businesses not only reduce costs but also increase energy efficiency and strictly control emissions in production.

Associate Professor, Dr. Nguyen Van Viet: 'Enterprises must proactively change'. Photo: Organizing Committee.

Ms. Nguyen Thi Ngoc Bich, Director of Supply Chain for Southeast Asia, representing AB InBev Vietnam, said that the company has invested in an energy management system, expanded recycled packaging, developed low-alcohol or non-alcoholic products, and implemented many water conservation programs. “Sustainable development is no longer an option but a core strategy of the company,” she affirmed.

According to Associate Professor Dr. Nguyen Van Viet, with a population of 100 million people, rapidly increasing income and spending needs, Vietnam is one of the most dynamic and potential markets in the region. The beverage industry currently ranks 3rd in the group of sustainable development industries, has a diverse supply chain and is deeply integrated with international trade agreements. "We have enough foundation to break through; the problem is that businesses must proactively change, cannot wait until policies force them to do so," he recommended.

The transformation of the beverage industry, therefore, is not only about investing in technology or complying with environmental regulations, but also about changes in management thinking, corporate culture and market approach. As consumers demand transparency, regulators tighten green standards, and international corporations put low-carbon criteria into their investment strategies, Vietnamese enterprises need to reposition themselves in the global value chain sooner.

Source: https://nongnghiepmoitruong.vn/cong-nghe-thuc-day-xanh-hoa-nganh-do-uong-d782941.html

![[Photo] Da Nang: Hundreds of people join hands to clean up a vital tourist route after storm No. 13](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/07/1762491638903_image-3-1353-jpg.webp)

Comment (0)