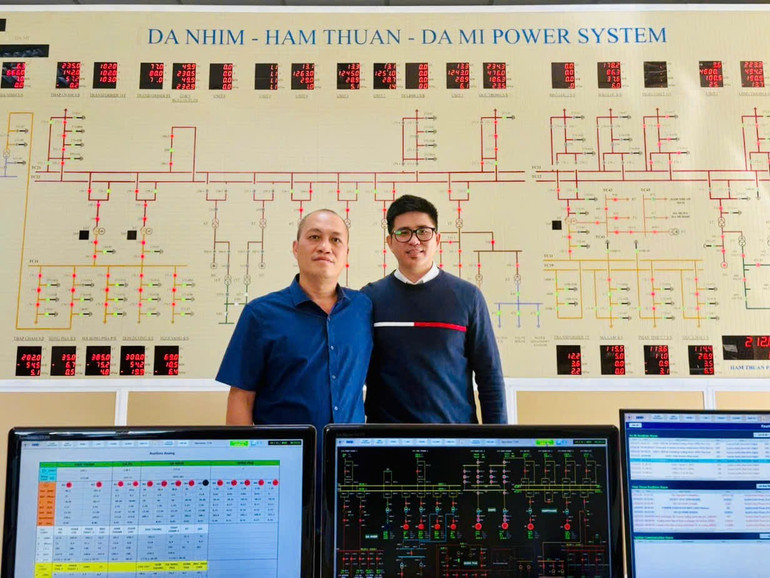

At Da Nhim-Ham Thuan-Da Mi Hydropower Joint Stock Company (DHD), this approach has been strongly implemented through proactive solutions, linked to production practices.

Journey to master operating technology

From many years of practice, the problem is not only the safe operation of power plants, but also the narrowing of the gap between information technology and industrial control systems, two seemingly separate but closely linked fields in modern power production. Power plants can only operate stably when the engineering team has a deep understanding of the signal transmission and reception structure and working protocols of control systems such as DCS, SCADA, PLC.

From these concerns, many engineers at DHD have proactively researched and studied the control structure of the generators, thereby forming an approach that combines digital knowledge with practical operating experience. This is an important premise for the unit to move from "just using" to "mastering" technology. Engineer Trinh Xuan Duy, Da Nhim-Ham Thuan-Da Mi Hydropower Joint Stock Company affirmed: if the system is not firmly grasped, the unit will depend on the contractor whenever an incident occurs. When engineers proactively have data, configuration and control principles, all technical decisions become faster and more effective.

The beginning of that journey was the deployment of the Operation Control Center (OCC) system - a pioneering remote control system in the Vietnamese electricity industry. In the first phase, the team of engineers at the factory proactively participated in programming, calibration testing, building remote control connections, standardizing operating data and integrating generators into the common system. This is an important step to create a solid technical foundation, helping to save operating costs and significantly reduce dependence on foreign contractors. Engineer Trinh Xuan Duy said that in the first phase, the research team programmed and integrated each generator into the system themselves. Each time a new configuration is completed, it increases autonomy by one step.

Actively maintaining, modifying and expanding the system has helped DHD reduce the number of direct operators, save maintenance costs and improve the ability to handle technical situations. This achievement was recognized by the Ministry of Industry and Trade with a Certificate of Merit in 2017. Chairman of the Board of Directors of DHD Le Van Quang said: with the OCC system, the company will continue to upgrade to manage and operate the hydropower cluster effectively.

The driving force for innovative research

Following that spirit, many innovative solutions have been formed from operational practices: redesigning the control interface (HMI), rebuilding monitoring software when the old system has problems, standardizing operational data, configuring new warnings, or developing solutions to replace proprietary equipment with common hardware combined with simulation models. These methods help save significant investment costs, extend the equipment life cycle and increase flexibility for the entire system.

From reprogramming control devices, building open software architectures to testing on simulation models, in-house technology solutions have proven the proactive capabilities of power generation units in the context of increasingly high operational requirements.

Chairman of the Board of Members of EVNGENCO1 Nguyen Tien Khoa affirmed: digital transformation is the path to success for EVNGENCO1. EVNGENCO1's goal is to become a digital enterprise with a strong culture, one of the power generation corporations with advanced technology, modern management and high expertise, operating effectively and sustainably.

With the orientation of innovation as a strategic breakthrough in the period 2025-2030, EVNGENCO1 is implementing a series of drastic actions - from building a technology ecosystem, developing intellectual human resources to comprehensive digital transformation. In particular, EVNGENCO1 has established a "Core team of personnel applying science, technology and innovation in Power Generation Corporation 1" (Tech-CoE EVNGENCO1). This action demonstrates EVNGENCO1's long-term vision in building a technological "brain", where new ideas with high application value are researched, tested and nurtured in practical operations. Taking people as the center of every strategy, EVNGENCO1 considers each officer, engineer and operator as a "creative cell" - those who understand the reality best and are also those who are capable of finding solutions to their own problems.

Innovation does not start with technology but with thinking, with the question “can we do better?” and with the belief that every small initiative can create a big change. Above all, it is the spirit of “dare to think-dare to do-dare to create” that is spreading strongly throughout the system, becoming the driving force for EVNGENCO1 to continue to pioneer, break through and create positive changes for a sustainable future. This spirit is becoming an important driving force to help EVNGENCO1 improve its technological autonomy, optimize control work and ensure operational safety, contributing to the task of ensuring stable power supply for socio -economic development.

The Corporation aims to digitize all core operating processes and effectively exploit data for operations by 2030. Each factory will have at least 10 technical innovation initiatives each year, and new technology application platforms such as AI, IoT or Big Data will be used for maintenance, early warning and asset management. Along with that, the movement to compete in innovation and digital transformation will be widely launched, arousing the spirit of learning, improving digital skills, and popularizing technological knowledge to each officer, engineer and worker.

Source: https://nhandan.vn/doi-moi-tu-duy-cong-nghe-de-toi-uu-hoa-van-hanh-nha-may-dien-post927452.html

![[Photo] Parade to celebrate the 50th anniversary of Laos' National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764691918289_ndo_br_0-jpg.webp&w=3840&q=75)

![[Photo] Worshiping the Tuyet Son statue - a nearly 400-year-old treasure at Keo Pagoda](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764679323086_ndo_br_tempimageomw0hi-4884-jpg.webp&w=3840&q=75)

![[Video] Protecting World Heritage from Extreme Climate Change](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/03/1764721929017_dung00-57-35-42982still012-jpg.webp)

Comment (0)