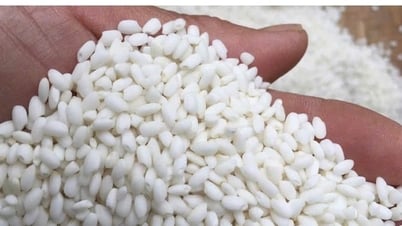

Using rice husks, the research team of Associate Professor, Dr. Le My Loan Phung designed materials to manufacture Li-ion batteries at low cost.

The research was led by Associate Professor, Dr. Le My Loan Phung, University of Science, Vietnam National University, Ho Chi Minh City (APCLab) and colleagues since 2020.

She said that rice husks contain an average silica (SiO2) content of about 10.6%. This is an important component that can be used to make Li-ion rechargeable batteries. The group proposed and was sponsored by the Vingroup Innovation Fund (VinIF) to research the process of synthesizing electrode materials from rice husks to test the production of 4V Li-ion rechargeable batteries in coin cell and pouch cell forms. Coin cell batteries are used in watches, heart rate monitors, personal computers and pocket batteries for phones and compact electrical devices.

Dr. Phung works in a vacuum chamber, during the button battery assembly process. Photo: NVCC

The research team took rice husks from Tan Tru district (Long An), washed them, dried them, then heated them for one hour in an inert gas condition, ground them into rice husk ash and mixed them with solid Potassium Hydroxide (KOH). This mixture was then heated in an inert gas condition, ground and washed. After the drying step, the final product was a dry, gray-black powder, also known as carbon silica composite material (C/SiO2).

The team has developed a synthesis process that can produce 350g of C/SiO2 material from 1kg of rice husk, with a selling price of about 50 USD/1000gr. After 2 years of trial production, the research team has been able to master the technology of assembling complete button batteries and pocket batteries using C/SiO2 material from rice husk.

Diagram of the silica material manufacturing process. Photo: Research team

Associate Professor Phung said that silica materials are porous, allowing lithium ions to move and intertwine within the structure to convert into electricity. APCLab takes advantage of this property of the material to design a structure suitable for rechargeable batteries. Depending on the energy form of each type of battery, the material is designed to calculate the amount used. Typically, each button battery only needs a few dozen mg of rice husks, while larger batteries require about 10-20g.

Currently on the market, most rechargeable batteries are made from graphite material, which is mined and refined from coal ore. This material costs about 100 USD/100gr and the process of finding raw materials can cause environmental pollution.

Dr. Phung assessed that silica material has the potential to completely replace graphite material in terms of cost, efficiency and environmental protection. This expands the potential market for rice husks and brings great profits to farmers.

In the future, the research team plans to optimize the product based on economic cost. According to current estimates, button batteries made from rice husks can be sold for $7-8/unit and pocket batteries for $30/unit.

Button batteries made from rice husks are being tested. Photo: Research team

Associate Professor, Dr. Nguyen Dinh Quan, Head of the Biofuel and Biomass Laboratory, University of Technology, Vietnam National University, Ho Chi Minh City, assessed that silica is known to be used as an additive for Li-ion rechargeable battery electrodes because of its ability to increase battery capacity many times. Its disadvantage is that the electrode is prone to volume expansion, but this can be overcome by using nano-sized silica particles. APCLab has adopted similar studies in the world to apply shaped silica in rice husks as a battery electrode additive. Silica in rice husks is dispersed at low density, when the rice husks are pyrolyzed, it will form a mixture of carbonized carbon that blends with nano-sized silica.

"This method is simple but highly effective, and can help a rice-growing powerhouse like Vietnam create high added value if the research project is successful," said Dr. Quan.

According to statistics, Vietnam is the second largest rice producing country in the world with an estimated average output of about 44 million tons/year, the rice husk ratio is about 20-22%, or nearly 9 million tons.

Associate Professor, Dr. Le My Loan Phung spent 6 years studying and researching in the field of rechargeable batteries in France and 9 years working on topics related to electrochemical batteries. She was invited to participate in research at the Institute of Materials Chemistry and Engineering - Kyushu University, Japan on the project of electrolytes for batteries and the project of developing advanced materials for batteries (Consortium Battery Material Research) at the Pacific Northwest National Laboratory (USA). The female doctor participated in and led 9 research topics, published 80 international articles and 60 domestic articles, along with many valuable awards and scholarships from prestigious organizations.

vnexpress.net

![[Photo] Prime Minister Pham Minh Chinh chairs conference on anti-smuggling, trade fraud, and counterfeit goods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/14/6cd67667e99e4248b7d4f587fd21e37c)

Comment (0)