At the workshop "Sustainable development and green transformation in industrial production" organized by the Department of Innovation, Green Transformation and Industrial Promotion ( Ministry of Industry and Trade ) within the framework of the Autumn Fair 2025, many energy-saving solutions applying artificial intelligence were introduced.

Mr. Le Tuan Minh, Solution Management Department, Daikin Vietnam Joint Stock Company said: Daikin Vietnam has developed a central air conditioning management system (Chiller) integrated with artificial intelligence, helping to simulate, analyze and automatically adjust operations. This solution optimizes performance, significantly reducing power consumption.

Energy management technology integrated with artificial intelligence helps simulate, analyze and automatically adjust operations to achieve maximum efficiency with the lowest power consumption. Illustration photo: Trung Nguyen.

According to Daikin Vietnam representative, thanks to the ability to simulate all operating data, continuously calculate, analyze, learn and adjust operating parameters to achieve maximum efficiency with the lowest energy consumption, Daikin's artificial intelligence management system helps buildings, factories and industrial parks significantly reduce operating costs and CO2 emissions, while extending equipment life. The application of smart technology in industrial operations not only brings economic efficiency, but also opens up a sustainable direction for the green transformation and digital transformation of Vietnamese enterprises.

Sharing Japan's experience in reducing emissions, Mr. Kasuya Tomotoshi, senior technical expert of Toshiba Vietnam, said: The Japanese Government has legislated energy saving policies applied nationwide. In particular, the electric motor industry is identified as one of the largest electricity consuming sectors, so it is necessary to apply the IE3 energy efficiency standard (high efficiency). The two main groups responsible for implementation are motor manufacturers and importers, who are required to report annually to the Japanese Government on progress and implementation results.

Currently, Toshiba is researching the application of high-efficiency motors combined with smart inverters and artificial intelligence control. With the current trend of motor conversion in the world, the proportion of IE3 efficiency motors or higher will account for about 70% in 2025, and will continue to increase. This is a potential market, because high-efficiency motor lines are a very effective solution to help businesses save electricity, significantly reduce energy costs, and contribute to achieving the goal of carbon neutrality by 2050.

Statistics show that motors account for 55% of industrial electricity consumption, but only about 25% of motors are currently used with inverters. In particular, in areas such as industrial pumps and fans, the application rate of inverters is only 22.7%. Thus, the remaining 75% is a huge space for businesses to deploy, contributing to increasing energy efficiency and reducing emissions.

Source: https://nongnghiepmoitruong.vn/ung-dung-tri-tue-nhan-tao-quan-ly-nang-luong-trong-san-xuat-cong-nghiep-d782065.html

![[Photo] Ca Mau "struggling" to cope with the highest tide of the year, forecast to exceed alert level 3](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762235371445_ndo_br_trieu-cuong-2-6486-jpg.webp)

![[Photo] Government holds a special meeting on 8 decrees related to the International Financial Center in Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762229370189_dsc-9764-jpg.webp)

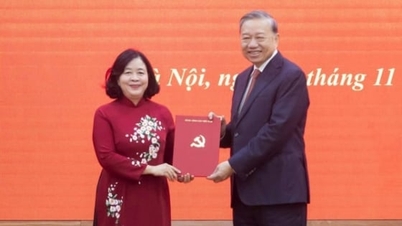

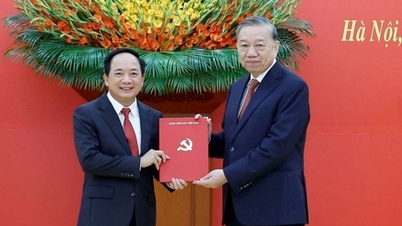

![[Photo] Comrade Nguyen Duy Ngoc holds the position of Secretary of the Hanoi Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762234472658_a1-bnd-5518-8538-jpg.webp)

![[Photo] Ho Chi Minh City Youth Take Action for a Cleaner Environment](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762233574890_550816358-1108586934787014-6430522970717297480-n-1-jpg.webp)

![[Photo] The road connecting Dong Nai with Ho Chi Minh City is still unfinished after 5 years of construction.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762241675985_ndo_br_dji-20251104104418-0635-d-resize-1295-jpg.webp)

Comment (0)