For many people, the image of a factory in their mind is of square, gloomy buildings, the rumbling sound of machinery, layers of workers moving around urgently, or layers of black dust coming from towering chimneys.

But that descriptive essay would be criticized as "unrealistic" if the assignment was to describe Canifa's production complex in Van Giang, Hung Yen .

About 20km from Hanoi , the Canifa factory is located next to a busy provincial road passing through Ecopark, looking more like a park than a factory.

At the very beginning of the “park” is a transparent operations building that rises like a fortress, surrounded by a moat filled with swimming Koi fish, with the only entrance being a bridge.

Looking at this glass-operated building, many people will think of the office buildings of world- famous technology companies, which are carefully crafted with green spaces, emphasizing aesthetics and openness - factors that help increase work productivity.

Planned in a checkerboard pattern, the Canifa Van Giang complex clearly divides each area of the factory, warehouse, lab, operating building and multi-purpose area, with spacious separate spaces. Interspersed in the middle are large lawns, trellises of dracontomelon and chieu lieu planted in long rows, embracing the four corners of the campus. A rare sophistication for a project that emphasizes optimization and productivity.

“As someone in the fashion industry, I consider a factory not only a place to create products but also a place to be beautiful. It must be a place to inspire myself, the workers and even the partners who visit here,” Ms. Doan Thi Bich Ngoc, CEO of Canifa, shared about the unique design of the complex.

In operation for nearly 10 years, Canifa's Van Giang complex in Hung Yen has a scale of more than 3 hectares, serving the working needs of nearly 400 people. This is one of the few factories that, although built a long time ago, still ensures modernity, follows the sustainable trend, and is especially awarded LEED certification - a prestigious certificate for green buildings, complying with standards on energy saving, emission reduction, and environmental protection.

During the evaluation process, LEED confirmed that the complex saves 20-40% of water compared to conventional buildings. Wastewater during use is collected, filtered and reused for the internal ecosystem, watering plants or even used directly to raise Koi fish.

Trees and lawns here account for 30% of the construction area. The buildings are all made of glass or make the most of glass. Workplaces have natural light, limiting the use of artificial energy.

In the US, LEED is considered a mandatory certification, which not all construction owners like. But in Vietnam, Canifa voluntarily "put its head in the bag".

“After the factories built 20 years ago, we want to open new and better factories. Van Giang is one of the first private factories aiming to achieve LEED certification. We want this to be a place in harmony with nature as well as following the general trend of the whole world,” Ms. Ngoc shared.

In addition to the main operating building which is entirely made of glass, there is also a multi-purpose area including a canteen and a common living area with a shape that ensures two functions: "eat below, play above". Below is a common dining room for all employees with four transparent sides, on the roof is an outdoor activity space, including a tennis court.

Large open areas and green lawns around the factory are often where employees work freely in groups, stimulating creativity in the fashion industry, creating a better balance between work and life, right during working hours instead of having to wait until days off.

“Canifa’s philosophy is to do business based on real value. Transparency is what we value. From the office area to the working area, the kitchen area, there are transparent glass doors, there is no private space. Everyone can see what each other is doing. This complex itself is a reflection of Canifa’s philosophy,” Canifa CEO described.

Since its early days of operation, Canifa has been aware that the fashion and textile industry has had a negative impact on the environment, as it is one of the three manufacturing industries that pollute water sources and create waste during the production process as well as after use.

“That is the harsh reality of the industry. To solve that problem, we believe that Canifa must identify sustainable fashion as a long-term path,” said Ms. Pham Thi Thuy, Head of Canifa Quality Standards Department.

“Canifa does business based on real values. We pay attention to the origin and quality of the raw materials, and every process leading to the final product ensures the least impact on the environment and the health of consumers.”

This method has only been generalized and named with the concept of “sustainable, green” in recent years. But for Canifa, that orientation has been in mind for 20 years.

“We determined that we had to do both sustainability and fashion in parallel,” Ms. Thuy emphasized.

Green and sustainable is not just a shiny glass shell outside the factory, it is also a multi-step process from choosing raw materials, suppliers, testing, design, production. The fastest and most accurate way to “green” every step is to apply proven standards in the world.

Canifa uses up to 70% natural materials in production to minimize environmental impact. Especially materials that have achieved international certifications such as Cotton USA, a fabric made from 100% imported cotton fibers from the US, more environmentally friendly than blended fabrics, or Australian wool with outstanding warmth retention, good elasticity, can be stretched up to 20,000 times without breaking.

“Canifa is one of the brands with many firsts. It is the first manufacturer to have OEKO-TEX certification since 2014, the first to bring American quality cotton to Vietnamese customers, and the only domestic Vietnamese brand to be a member of Cotton USA since 2017, as well as an international certificate for Australian wool from Woolmark,” Ms. Thuy listed Canifa’s collection of many bullet points of standards.

“The above mentioned materials and standards have only been popular in the market for the past 2-3 years, but Canifa has been using them for nearly ten years.”

To learn more about these new things, Canifa went to production areas in many countries around the world, working with experts to see how they affect the environment, people or local ecology, and what advantages they have over conventional raw materials. When organizations provided specific figures, Canifa believed that this was exactly what they were looking for.

The long-standing Vietnamese fashion brand also became interested in the OEKO-TEX global safety certification in 2014, when not many domestic brands were interested.

As one of the most prestigious certificates today – OEKO-TEX will strictly test products from raw materials to finished products to ensure that they do not contain toxic substances before reaching consumers.

“While current regulations only require a few dozen compounds to be met, OEKO-TEX tests up to 1,000 compounds. These compounds will be updated or eliminated annually,” Ms. Thuy explained.

“Products with this certification mean that customers are using products with the highest safety level currently with global standards.”

To date, Canifa is still one of the few domestic brands with OEKO-TEX certification.

Playing by international standards is not easy. They have strict, transparent and long-term rules. Plus, it costs money.

Ms. Thuy said that the international certificate here is not only issued once and valid for life. The certification body will monitor and evaluate it annually. “The production process must be very transparent and clear to be renewed,” she emphasized.

Despite the high cost and complicated process compared to traditional methods, Canifa does not think the company is making things difficult for itself or "showing off".

“We don’t think much about difficulties. International standards bring Canifa advantages in many other aspects. The quality of the shipments is more stable and uniform, the production process is shortened, saving labor, production time, and errors are greatly reduced. It may be difficult at first, but once a stable process is established, everything will fall into place.”

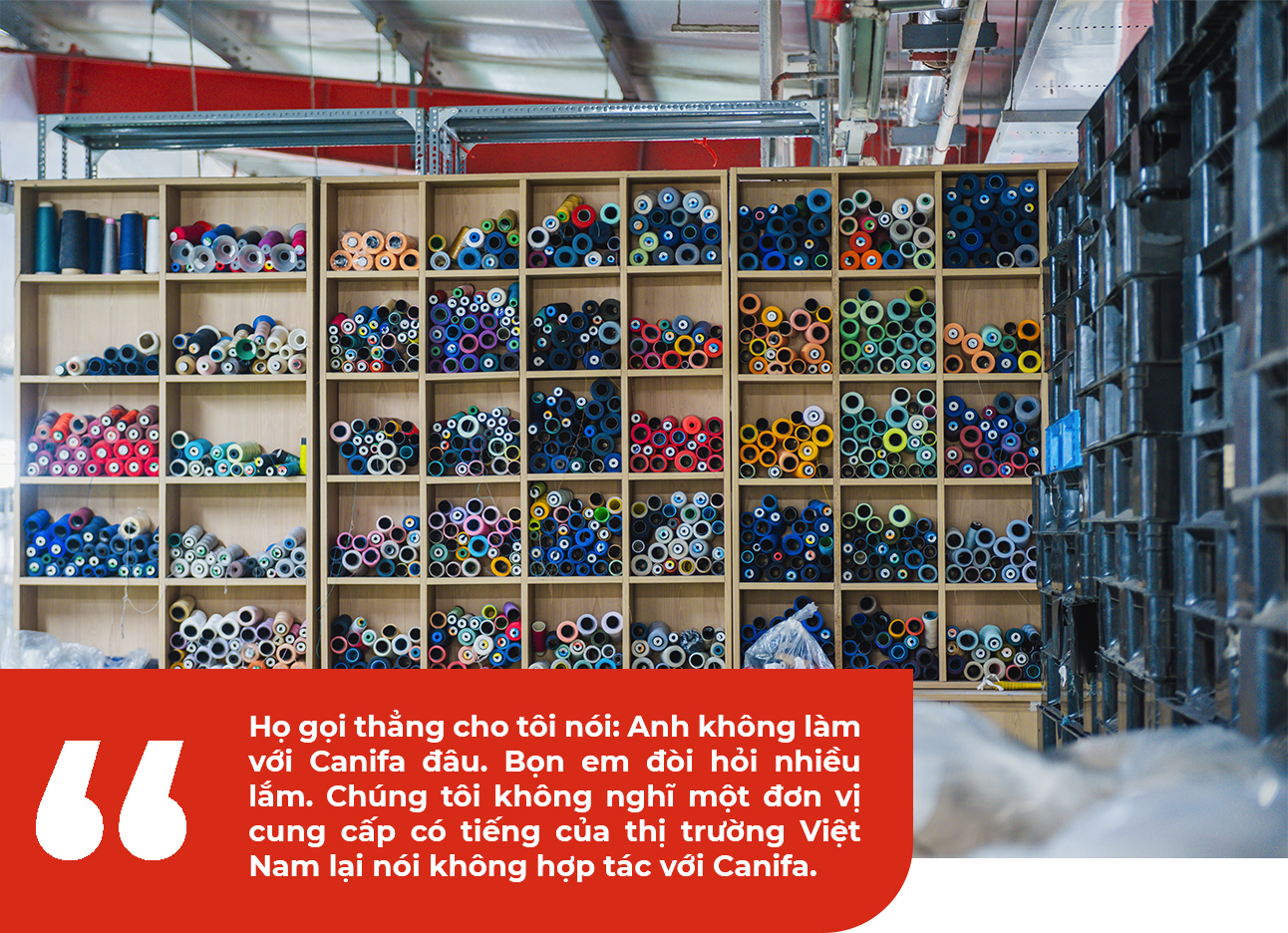

One special thing is that when following international standards, Canifa can only buy fabric or other accessories from suppliers that are also on the list. Even the secondary stages such as printing and embroidery are also designated as qualified processing units.

In the early stages, it was very difficult for Canifa to find domestic suppliers. At that time, processing units still had the mindset of selling products instead of improving quality.

“Those standards are very strict. In 2014, very few domestic fashion enterprises in Vietnam had built a quality system and ensured those certificates, forcing us to buy raw materials from abroad,” Ms. Thuy shared.

This also led to an ironic situation when Canifa’s requirements were so complicated that the domestic supplier abruptly announced that they would stop working with them. “They called me directly and said: You will not work with Canifa. We are demanding too much,” Ms. Thuy recounted.

“We don’t think a reputable supplier in the Vietnamese market would say they won’t cooperate with Canifa. But when we understand it carefully, we see that Canifa’s standards and those of the actual partner are highly compatible. This is just a lack of understanding.”

Now that the joints are fitted, Canifa only needs to provide the standards and materials and they will be met immediately, without any questions. Canifa's domestic raw material supply currently accounts for 70%.

“We want to expand our search for domestic suppliers. Foreign suppliers may understand the process and standards better, but domestic partners are also making more efforts to improve quality,” Ms. Thuy shared.

After 10 years of "holding the lamp to light the way", more and more fashion units and suppliers have started to follow the path of green and sustainable standards, showing the positive effects from Canifa.

“I think Canifa has contributed to the green and sustainable trend in the Vietnamese textile and fashion industry. From Canifa’s initial difficult requirements, the partners also motivated themselves and were determined on the path of building a standard system and conquering international certificates. We resonate to create a green and sustainable standard ecosystem that develops together,” Ms. Thuy proudly said.

“As a dedicated unit, we also hope that other brands will increasingly understand and be aware of sustainability to join Canita in building an increasingly high-quality Vietnamese fashion supply chain.”

Difficult and costly, but the pursuit of international standards has yielded sweet results, demonstrated by the trust from customers as well as the enhanced brand image over the years.

“When we conducted a customer survey, there were many positive reviews about the reliability and quality of the products. We think this is a worthy result for our efforts in choosing the difficult path.”

“We have about 1,200,000 registered members, of which 600,000 are loyal customers. The relatively high brand loyalty is the answer to everything.”

After quality standards, the more important aspect is the finished product that reaches the user. Canifa's philosophy is to create products that are fashionable enough to meet the tastes but still minimalist to avoid going out of fashion quickly, focusing on quality and durability to help prolong the life cycle, thereby contributing to reducing fashion waste.

“Canifa products have a basic design, easy to wear in many situations, from going to work, going out, even attending parent meetings, can be used in many different situations, increasing the frequency of use and minimizing the need for customers to buy many products for each situation,” said Ms. Thuy.

“The seams must also be neat and of good quality to have a long life cycle. If it can only be worn once or twice, it cannot be called sustainable.”

Products from the factory delivered to every store across the country, whether expensive or cheap, are provided with a full label system so that customers clearly understand how to use, materials, origin, and safety standards.

For many people, those layers of labels are not worth paying attention to, even annoying, but for Canifa, it is a long journey of international standards attached to products bearing the mark "Made by Vietnam".

“Canifa’s mission is to bring international quality fashion products at the most reasonable prices. Vietnamese customers deserve that,” said Ms. Thuy.

Marking the relentless efforts with a sustainable development model and constant innovation, in 2024, Canifa was honored to be awarded the title of Vietnam National Brand and Innovative Brand for the second consecutive time.

Source: https://phunuso.baophunuthudo.vn/canifa-chuyen-ve-nhan-hang-thoi-trang-ky-tinh-nhat-viet-nam-doi-tac-tung-tuyen-bo-nghi-choi-vi-doi-hoi-qua-nhieu-193250207133220706.htm

![[Photo] Flooding on the right side of the gate, entrance to Hue Citadel](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761660788143_ndo_br_gen-h-z7165069467254-74c71c36d0cb396744b678cec80552f0-2-jpg.webp)

![[Photo] National Assembly Chairman Tran Thanh Man received a delegation of the Social Democratic Party of Germany](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761652150406_ndo_br_cover-3345-jpg.webp)

![[Photo] Draft documents of the 14th Party Congress reach people at the Commune Cultural Post Offices](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761642182616_du-thao-tai-tinh-hung-yen-4070-5235-jpg.webp)

![[Photo] President Luong Cuong attends the 80th Anniversary of the Traditional Day of the Armed Forces of Military Region 3](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761635584312_ndo_br_1-jpg.webp)

Comment (0)