On the morning of December 5, in Chan May-Lang Co commune, Hue city, Kim Long Motor Hue Joint Stock Company held the inauguration ceremony of the Yuchai engine manufacturing and production factory and shipped the first Yuchai engine.

But the greatest significance of the event lies not only in the inauguration ceremony, but in the ripple effect: a factory that can become a driving force contributing to elevating Vietnam's industrial sector.

From assembly to mastering the core process – a pivotal transition.

For many years, the Vietnamese auto industry has relied heavily on imported components, especially engines - the most complex part that determines product value.

The operation of Kim Long Engine Factory, with a more than 90% automated production line and the ability to retrieve data by engine code, marks an important turning point: Vietnam begins to reach the core of the automobile value chain.

When the engine body, crankshaft, cylinder head and many core components are produced domestically, increasing the localization rate will be truly meaningful. This is the foundation for reducing trade deficit, increasing added value, and at the same time developing the precision mechanical industry - the foundation of modern industrialization.

Chan May - Lang Co: From a favorable location to a new growth pole

The factory is located in Chan May-Lang Co Economic Zone, a gateway area with a deep-water port, located on the North-South corridor. This is not only a beautiful location for a factory, but also the starting point for a mechanical-automotive industrial cluster. When a large-scale engine factory operates, it will attract precision mechanical enterprises, casting-forging-machining enterprises, R&D and quality control centers, industrial logistics systems, vocational and engineering training networks and a new industrial urban area.

A project that can initiate a new industrial growth pole in the Central region. This is an opportunity for this economic region to escape the phase difference between services and manufacturing, and enter a deeper manufacturing value chain.

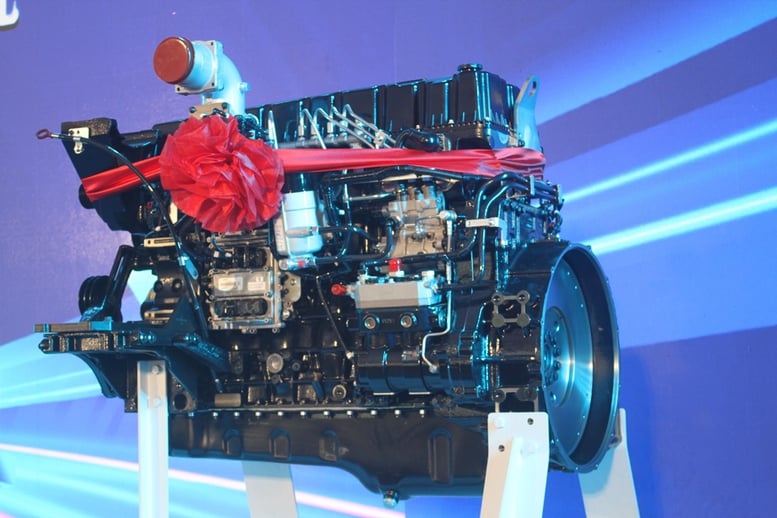

Entering engine manufacturing is a major step forward - Photo: Kim Long Motor's engine is completed and officially shipped out.

Vietnam has the opportunity to elevate its position within ASEAN.

In the ASEAN region, the auto industry has long been clearly differentiated: Thailand has become the "Detroit of Asia", Indonesia has the advantage of market size and mass assembly, while Malaysia has developed towards national brands. Vietnam, despite being decades behind, is facing a rare opportunity to step up to a new value ladder.

The difference of the current period lies in the strategic shift of global supply chains. The trend of reducing dependence on a single source and the requirement for flexibility in production chains are forcing multinational corporations to relocate production capacity, especially in the mechanical-manufacturing, semiconductor, automobile and electronic equipment industries.

In this context, Vietnam possesses three strategic advantages:

1. ASEAN's central position with high stability, helps international businesses easily access both the Northern supply chain (China, Korea, Japan) and the Southern chain (Thailand, Indonesia).

2. Industrial capacity is on the rise, especially after Vietnam attracted large-scale projects in electronics, batteries, materials, and precision engineering.

3. A policy of deep integration, with a global network of FTAs, creates a significant tariff advantage compared to many other ASEAN countries.

In that context, Vietnam's entry into automobile engine production for the first time is not only a technical advance, but also a strategic message to the regional market: Vietnam is ready to take on more complex, higher-value stages in the automobile value chain.

If guided by a smart industrial policy, the Kim Long Motor Factory could play three strategic roles:

First, become a "technology fulcrum" for Vietnam to deeply penetrate the supply chains of Thailand and Indonesia, which need to diversify the supply of components and engines in the region.

Second, creating a new competitive position for Vietnam will help us not only attract FDI in assembly but also attract core component manufacturers, from molds, casting and forging to sensors and control chips.

Third, creating conditions for the formation of Vietnam's "design-manufacturing capacity", a prerequisite for moving from the position of "participant" to "shaper" in the ASEAN automobile industry.

In other words, for the first time, Vietnam has the opportunity to shift from a follower to a leader in the regional division of production. But this opportunity will not come by itself. It will only come when Vietnam has policies bold enough and vision far enough to turn a factory into a platform, and a platform into a national competitive advantage.

The bus manufacturing plant of Kim Long Motor was researched, designed, and built by Vietnamese engineers.

Correctly identify challenges so as not to miss opportunities

A meaningful event like the inauguration ceremony of Kim Long Automobile Engine Manufacturing and Production Factory becomes more complete when we fairly recognize both the opportunities that are opening up and the challenges that need to be dealt with soon.

1. The challenge of substantial localization. Entering engine production is a big step forward, but for the value to spread strongly, Vietnam needs to ensure that the localization rate is more substantial. The transfer of modern technology, improving the capacity of domestic enterprises and gradually mastering core components will determine the level of long-term success.

2. Challenges from green technology trends. The global auto industry is rapidly shifting to electric vehicles, hybrids and clean powertrain solutions. This opens up opportunities and poses strategic requirements for Vietnam: it must both develop traditional engines to serve current needs and proactively prepare for the next generation of technology so as not to be "out of step" in the future.

3. Challenges of the supporting ecosystem. A modern engine factory can create a large spillover effect, but the efficiency will be much higher if there is a strong supporting business ecosystem accompanying it. Upgrading domestic mechanical, casting, forging, materials and components enterprises is a key condition to create a sustainable domestic value chain.

4. Challenges of highly skilled human resources. The engine industry requires a team of engineers, technicians and skilled workers with increasingly high qualifications. This is both a pressure and an opportunity for universities and vocational training institutions to cooperate more closely with businesses, forming training models linked to production practices.

Looking at these challenges with a receptive and constructive spirit does not diminish the significance of the event. On the contrary, it is a necessary preparation step to turn the inauguration milestone into a launching pad for long-term development. When the challenges are properly resolved, Kim Long Engine Factory will not only be a successful project, but can also become a strategic fulcrum for a rapidly growing industry.

From industrial milestone to national resilience

For the establishment of the Kim Long Engine Factory to not only be a symbolic milestone, but to truly become a driving force to elevate Vietnam's industry, a synchronous policy response system with a long-term vision and effective implementation is needed. This is the time when Vietnam can shift from "technology adoption" to "building national industrial capacity".

First, ensuring real localization - the key to increasing value. Localization is not just the percentage of domestically produced components, but the ability to master technology and create domestic added value. To achieve that, the policy needs to establish a binding and measurable technology transfer roadmap; form joint laboratories and R&D centers between enterprises, universities and research institutes to develop design and testing capacity; independently evaluate the localization rate based on economic value and technology content, avoiding "formal localization".

If done well, Vietnam could not only produce engines but also build the foundation to move on to higher generations of technology.

Second, forming a supporting ecosystem around Chan May - Lang Co. An engine factory can only truly develop its strength when it has a strong enough supporting business ecosystem around it. Therefore, it is necessary to provide tax, land and credit incentives to attract mechanical, material and mold businesses to set up factories in the area; build a mechanism to "connect industrial supply and demand" so that Vietnamese businesses have the opportunity to participate in the supply chain of Kim Long and other car manufacturers in the region.

If this ecosystem is established, Chan May-Lang Co could become a regional-scale automotive and mechanical engineering industrial cluster, creating a ripple effect throughout Central Vietnam.

Third, invest heavily in technical human resources - a decisive factor. No industry can develop without a team of elite engineers and technicians. Training needs to be substantive, including: Expanding the dual training model of "learning-doing", linking training with production lines; establishing the Central Manufacturing Technology Center to serve the needs of upgrading skills and R&D; applying scholarships and preferential credits to attract students to the fields of mechanics, automation, and materials technology.

This is the soft power that determines the success of the industrialization strategy.

Fourth, regional planning with a vision of 20-30 years or even further. A large-scale engine factory requires a compatible industrial-logistics-urban infrastructure. Therefore, it is necessary to: Synchronously develop Chan May seaport, railway, road and warehouse infrastructure to reduce logistics costs; form a green-smart industrial urban area for experts and high-tech workers, create an attractive and sustainable living environment for tens of thousands of households, including schools, medical stations, etc.; systematic regional planning will turn Chan May-Lang Co into a new industrial destination of the ASEAN region, not just of Vietnam.

Fifth, prepare early for the future of green technology. The global trend is rapidly shifting to new transmission technologies. ; build a system of national standards and regulations for the green car industry, creating a legal environment for businesses to innovate technology.

The engine factory is just the first step. Mastering green technologies is the long road ahead for Vietnam to progress.

KIMLONG MOTOR Hue Industrial Cluster has transferred technology, invested in research and testing of hybrid engines, electric motors, fuel cells and clean energy solutions...

A door has opened; move forward with big thinking and strategic vision.

The inauguration of the Kim Long Automobile Engine Factory is a historic milestone for the mechanical and automotive industry in Vietnam. But the deciding factor lies in how we will continue after that milestone.

A factory can be inaugurated in a day. But an industry is only formed through years of vision, policy, and determination.

If Vietnam takes advantage of the opportunities from this factory to develop a supporting ecosystem, train human resources, upgrade technology and plan appropriate regions, this event will likely be remembered as the beginning of a new chapter: a chapter in which Vietnam steps up to a higher position in the global value chain, with a strong, confident mechanical industry and towards a green-clean-sustainable future.

Dr. Nguyen Si Dung

Source: https://baochinhphu.vn/viet-nam-da-lam-chu-cong-nghe-loi-cua-chuoi-gia-tri-o-to-102251210060942548.htm

![[Video] The craft of making Dong Ho folk paintings has been inscribed by UNESCO on the List of Crafts in Need of Urgent Safeguarding.](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/10/1765350246533_tranh-dong-ho-734-jpg.webp)

Comment (0)