A spate of electric vehicle fires in October, including high-end models like the Xiaomi SU7 Ultra, NIO ET7, Li Auto MEGA, Mercedes-Benz EQE, and Porsche Taycan, has once again brought battery safety to the forefront. Data and evidence show that the race for performance—from high energy density to ultra-fast charging—is coming at the expense of thermal stability and requiring more rigorous risk management (via 36kr.com).

High energy density: range advantage, pressure thermal stability

The transition from lithium iron phosphate (LFP) to lithium ternary (NCM/NCA) positive materials has increased energy density and extended operating range. However, compared with LFP, which has a stable crystal structure and is difficult to release oxygen, high nickel materials reduce thermal stability.

Market experience forced the industry to adjust: after incidents related to NCM 811 (GAC Aion S in 2020; General Motors recalled nearly 70,000 vehicles in 2021 due to high nickel battery risks, LG Chem paid $1 billion in compensation), the popular NCM ratio shifted to 5-2-3/6-2-2 to balance performance and safety. LFP is still widely present in the sub-200,000 yuan segment due to cost, while tri-component batteries are used for mid-range and high-end cars (for example, Tesla uses tri-component batteries for the long-range version, LFP for the standard version).

From 18650 to 4680, then CTP/CTC: volumetric efficiency and large cell risk

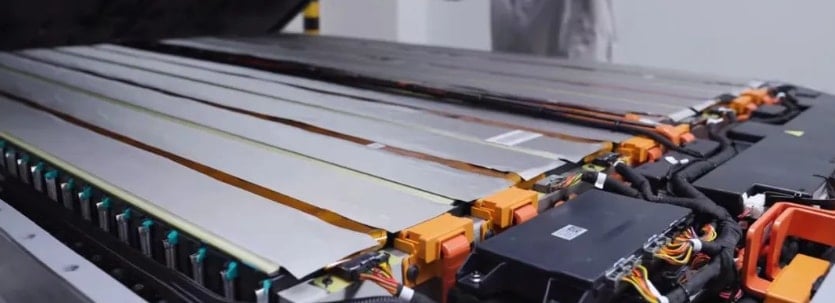

Along with materials, architectural improvements have helped to “compress” more energy into the same volume. The first Tesla Model S used a cell–module–pack structure: each module contained about 444 18650 cells, equipped with its own BMS and cooling pipes; a pack could have 16 modules, with fire-resistant materials. The trend since then has been to reduce and eliminate modules (CTP – Cell to Pack) and deeply integrate (CTC – Cell to Chassis).

Cylindrical cell size increased from 18650 to 21700 and 4680; on the cubic side, BYD optimized Blade to increase the volume utilization ratio by about 50%, pulling the cell capacity from 135 Ah to over 200 Ah. CATL with Qilin pushed the volume utilization ratio to 72%, surpassing the 63% milestone of 4680; CTC solutions are put into mass production from 2022–2023 respectively.

The downside: large capacity cells, when experiencing an internal short circuit, can diffuse heat quickly, forming hot spots and a more intense thermal chain reaction. The time from smoking to igniting is therefore very short and difficult to control. In addition to the cell, the pack packaging process is also a risk point: NIO recalled 4,803 ES8 cars in 2019 due to improper high-voltage wiring in the pack.

The 800V–10C fast charging race: better experience, narrower safety margin

Charging power = voltage × current. The first generation of 400V cars had charging rates below 1C. Tesla gradually increased the supercharger power from 90 kW (V1) to 250 kW (V3), adding about 250 km of range after 15 minutes of charging and at 2–2.5C rates.

Porsche Taycan pioneered the 800V platform with a 270kW fast charging capacity: increasing the voltage reduces current and heat loss, improving safety during high-power charging. Chinese manufacturers quickly caught up with 800V, raising the battery to 4C or more; charging capacities exceeding 400kW appeared on the market. In 2023, Li Auto MEGA announced the use of CATL Qilin 5C, with a maximum capacity of over 500kW. BYD stated the ability to charge 10C, "10 minutes enough for 600km"; according to industry testing, the maximum 10C current only lasts for a very short time.

In return, the insulation, protection, and arc-extinguishing requirements increase dramatically; the instantaneous short-circuit current is larger, and the thermal reaction can be more intense. At high currents, lithium ions embed/separate quickly, causing heat generation and promoting dendrites, shortening the lifespan. According to Li Bin (NIO)'s September share, the pursuit of supercharging comes at a cost, including the battery's lifespan. NIO uses slow charging at battery swap stations, aiming for 85% lifespan in 15 years. "Imagine if after 8 years of using the car, you have to spend 80,000 or 100,000 yuan ($11-$14,000) to replace the battery... this is an unacceptably high cost."

Fast charging milestones and voltage base (by source)

| System/vehicle | Ground/voltage | Maximum power | Note |

|---|---|---|---|

| Tesla Supercharger V1 → V3 | ~400V | 90 kW → 250 kW | ~250 km/15 minutes; speed 2–2.5C |

| Porsche Taycan | 800V | 270 kW | Reduce current and heat loss |

| Many Chinese companies | 800V | >400 kW | 4C battery or higher |

| Li Auto MEGA + CATL Qilin 5C | 800V | >500 kW | Announced in 2023 |

| BYD 10C charger | — | — | 10 min ~600 km; 10C current lasts very short (according to industry testing) |

Current technical solutions: cooling, thermal-electric separation, BMS optimization

Before solid-state batteries reach industrial scale, liquid battery optimization continues to be the main direction:

- CATL Qilin puts liquid cooling plate between cells to increase heat exchange; arranges pressure relief valve at the bottom of cell, separate from positive/negative pole at the top for “heat-electric separation”.

- The fine-grained graphite-coated negative electrode accelerates ion immersion, supports fast charging, and reduces the risk of “lithium plating.”

- The long-thin shape of the BYD Blade is beneficial for heat dissipation; the dense layout creates a structural support effect, reducing the need for traditional cross/longitudinal beams. However, concerns about ultra-long cell bending in a crash still exist.

- BMS is enhanced with real-time monitoring of voltage, current, temperature; circuit break and alarm when abnormal. However, instantaneous short circuit may exceed sampling/response speed.

Solid-state batteries: high potential, high hurdles

Solid-state batteries have been in development for three decades but have yet to reach industrial scale production due to R&D challenges, processes, and the cost of transitioning from the existing liquid battery ecosystem. Most automakers and battery manufacturers are not ready to make large investments at this time.

Conclusion: There is no absolute safety, only a learning curve

A well-balanced battery pack is a combination of materials, architecture, processes and BMS. In the race for performance, investment in safety must increase commensurately and information to users must be honest, avoiding concealing differences in risk.

Manufacturers aim to reduce the failure rate to ppb (parts per billion). However, for users, a “one in a billion” accident is still 100% when it happens. Each accident is both a warning and data for optimization, like how Tesla improved its BMS through early spontaneous combustions; Chinese car and battery manufacturers are also pursuing a similar learning and improvement path.

Source: https://baonghean.vn/an-toan-pin-xe-dien-danh-doi-giua-mat-do-va-sac-nhanh-10310036.html

![[Photo] Ho Chi Minh City Youth Take Action for a Cleaner Environment](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762233574890_550816358-1108586934787014-6430522970717297480-n-1-jpg.webp)

![[Photo] Ca Mau "struggling" to cope with the highest tide of the year, forecast to exceed alert level 3](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762235371445_ndo_br_trieu-cuong-2-6486-jpg.webp)

![[Photo] The road connecting Dong Nai with Ho Chi Minh City is still unfinished after 5 years of construction.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762241675985_ndo_br_dji-20251104104418-0635-d-resize-1295-jpg.webp)

![[Photo] Panorama of the Patriotic Emulation Congress of Nhan Dan Newspaper for the period 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/04/1762252775462_ndo_br_dhthiduayeuncbaond-6125-jpg.webp)

Comment (0)