|

| The “factory-park” model at Cao Ngan Thermal Power Company - TKV. Photo: Xuan Loc |

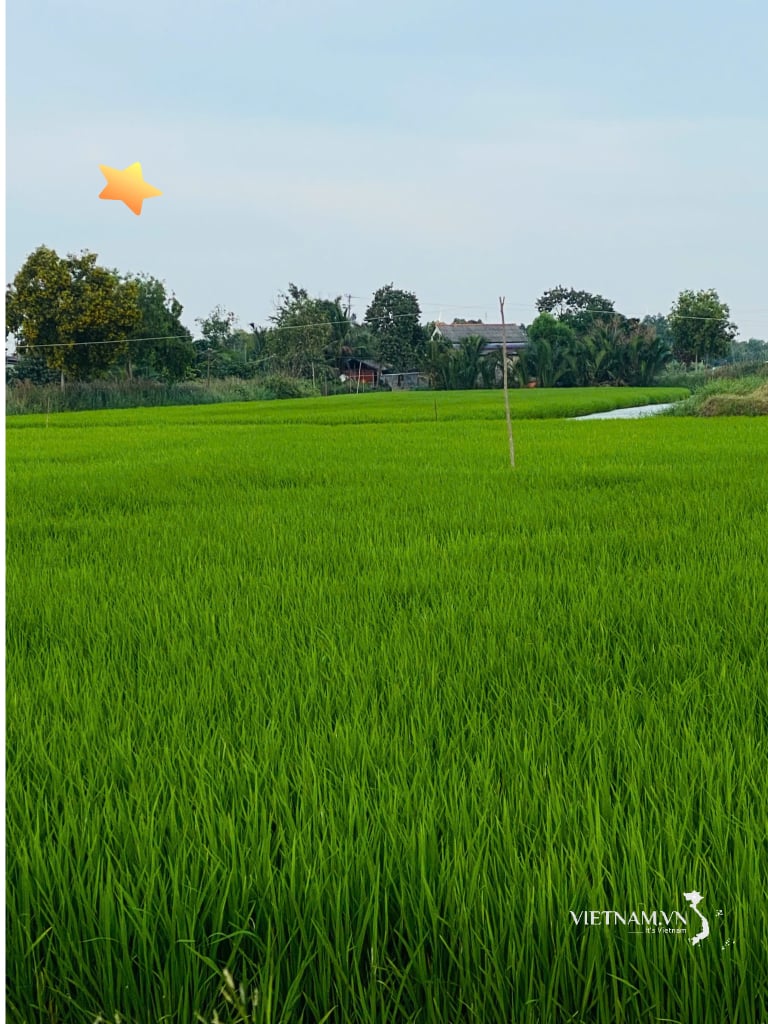

Environmental protection work is determined by the two units as a consistent orientation, associated with vision and specific actions. The two companies' leadership always considers stable production, safe operation and environmental protection as three organically linked factors. In the factory area, green trees are planted along the fence, the coal slag storage area has a covering system, and the wastewater treatment area is arranged separately from the main operating area.

These visual measures are just a visible part of a series of technical and management solutions to minimize environmental impacts. The “factory-park” model not only creates sympathy with the community but also brings a comfortable mindset to staff and workers during the working process.

Mr. Nguyen Duy Tung, a worker at the Operation Workshop, Cao Ngan Thermal Power Company - TKV, shared: Every time I come to the company, looking at the neatly trimmed green trees and the lively aquarium, I feel like I am in an ecological area. The fresh air helps us work more enthusiastically and creatively.

Mr. Tran Do Dat, a worker at the Operation Workshop, An Khanh Thermal Power Joint Stock Company, shared: The factory has a large area, the roads are always clean, and the trees are planted everywhere, creating a fresh atmosphere. To have such a working environment, in addition to the direction of the company's leaders, the important thing is the awareness of hygiene of each officer and employee.

|

| A green corner at Cao Ngan Thermal Power Company - TKV. Photo: Xuan Loc |

One of the most sensitive issues for coal-fired thermal power plants is emissions and coal dust. At both companies, the control of this area is effectively implemented. Specifically, at An Khanh Thermal Power Joint Stock Company and Cao Ngan Thermal Power Company - TKV, the units are equipped with electrostatic dust collection systems, each divided into four independent fields.

The filtration efficiency reaches 99.8%, ensuring that the dust concentration in the exhaust gas is within the allowable limit according to QCVN 22:2009/BTNMT. The exhaust gas and dust treatment processes are operated continuously, so that the factory's exhaust gas quality does not have a negative impact on the surrounding environment.

Through our research, we learned that both companies have installed automatic, continuous environmental monitoring systems. In addition, the Center for Natural Resources and Environment Monitoring under the Department of Agriculture and Environment conducts sample testing four times a year.

For solid waste, ash and slag have been certified to be in compliance with Vietnamese regulations. This waste source is reused as raw material for the production of construction materials and land leveling, after going through the stages of recycling, screening, crushing and storing in warehouses before being put into consumption at cement and brick production facilities and land leveling works.

Mr. Ngo Nhu Cuong, safety technician, Cao Ngan Thermal Power Company - TKV, said: On average, each year, with an output of more than 750 million kWh, the company generates nearly 200 thousand tons of ash and slag. The handling and transportation of this volume must be strictly implemented, in full compliance with environmental protection regulations such as washing the vehicle before leaving the company, covering it with tarpaulin, and attaching a waste transport sign. All transport units must sign a commitment not to cause pollution during the transportation process.

|

| An Khanh Thermal Power Joint Stock Company always pays attention to ensuring the environment for sustainable development. |

In addition to treating smoke, dust and exhaust gas to ensure the environment, the two companies also focus on planting trees on campus and participating in supporting the improvement of rural infrastructure. These efforts not only bring practical results but also contribute to building a "bright - green - clean - beautiful" environment, creating trust between the factory and the surrounding community. In the current context, when coal-fired thermal power is facing the strategic requirement of transitioning to clean energy, these activities are even more meaningful.

However, for the two thermal power companies in Thai Nguyen province, the practical task now is to ensure a stable and reliable power supply for the system, while applying emission reduction technology, optimizing furnace efficiency and persistently implementing a roadmap to minimize environmental impacts. Researching and investing in stronger emission control solutions, using alternative materials, as well as cooperating with partners to reuse by-products are considered necessary steps for the future.

From exhaust gas treatment systems, wastewater treatment tanks to ash management and community relations, it can be seen that businesses are choosing a proactive and responsible approach. To achieve sustainable development goals, it is necessary to continue investing in modern technology, improve transparency in environmental data disclosure and especially strengthen trust with local communities. Only when production is associated with environmental protection can the interests of businesses and people be ensured in a harmonious and long-term manner.

Source: https://baothainguyen.vn/tai-nguyen-moi-truong/202509/dam-bao-moi-truong-o-nha-may-nhiet-dien-1c042ea/

![[Photo] Draft documents of the 14th Party Congress reach people at the Commune Cultural Post Offices](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761642182616_du-thao-tai-tinh-hung-yen-4070-5235-jpg.webp)

![[Photo] National Assembly Chairman Tran Thanh Man received a delegation of the Social Democratic Party of Germany](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761652150406_ndo_br_cover-3345-jpg.webp)

![[Photo] Flooding on the right side of the gate, entrance to Hue Citadel](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761660788143_ndo_br_gen-h-z7165069467254-74c71c36d0cb396744b678cec80552f0-2-jpg.webp)

![[Photo] President Luong Cuong attends the 80th Anniversary of the Traditional Day of the Armed Forces of Military Region 3](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/28/1761635584312_ndo_br_1-jpg.webp)

Comment (0)