Durability has become one of the most important criteria when users choose to buy a smartphone. In the context of devices becoming thinner and lighter, integrating more components and being used in countless life situations, durability verification cannot stop at standard tests. What happens in OPPO's lab system in China shows that the current quality assessment process has shifted to a more rigorous model, capable of simulating many common risks of users.

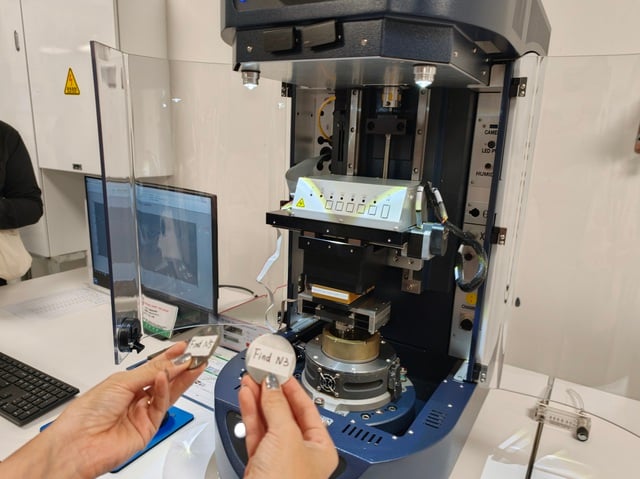

Mechanical force testing process on materials, simulating component durability in OPPO's laboratory

PHOTO: OPPO

One of the notable highlights is the company's approach to drop and impact testing. At the QE Reliability Lab (QE Reliability Lab), the phone is subjected to a series of tests that simulate real-life usage behavior. Micro drop tests take place more than 14,000 times from a height of 10 cm, simulating the situation of the device slipping out of hand on a table or bed. This is followed by a tumble test, which rotates the device 150 times in a rotating drum, equivalent to hundreds of falls from a height of 1 meter. In addition, free-fall tests from 1 to 1.8 meters on a stone surface are repeated multiple times to test the bearing capacity of the frame and components.

Water resistance and protection of components in humid environments are evaluated by various tests. The rain test simulates average rainfall while the device is in operation, then leaves it to dry for three days before disassembling to check for corrosion risk. Salt spray, artificial sweat, and cosmetics and household chemicals are also included to reflect hot and humid climate conditions and user habits.

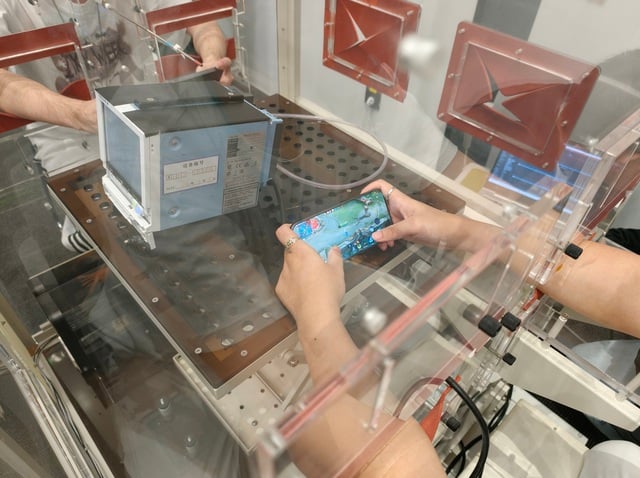

Liquid resistance testing with various solutions reflects users' daily habits in various environments

PHOTO: OPPO

To demonstrate its water resistance, OPPO tested the A6 Pro in real life by dropping it into a variety of common liquids. Not just cold or hot water, the test also included milk, dishwashing liquid, coffee, tea, juice, or soapy mixtures. These situations reflect the user's usage habits when bringing the device into the kitchen, bathroom, or high humidity environments. Reinforcing more than 20 points at risk of water intrusion with silicone gaskets and waterproof membranes shows an effort to minimize the risk of liquid infiltration even though the device is not designed to withstand standards higher than IPX8.

Close-up of the disassembled components of the recently launched Find X9

PHOTO: OPPO

Durability is also directly related to the strength of the internal components. At the Find X9 Pro disassembly workshop, many technical details show efforts to improve durability right from the design. The back is attached with a layer of glue only 0.1 mm thick but has high adhesion, requiring 15 minutes of heating before it can be removed. The camera cluster is sealed with specialized glue, creating a durability of up to 500 Newtons after pressing. The number of vents is reduced and concentrated to limit water ingress - an important factor in improving long-term water resistance.

Production process of glass used for OPPO smartphones

PHOTO: OPPO

The process of creating tempered ceramic glass - an important material in smartphones - is carried out at the Glass Preparation Lab. Here, machines simulate the entire process from heating at 1,500 - 1,600°C to micro-crystallization, allowing the formation of nano-structures that help limit the spread of cracks when the device is impacted.

Test using smartphones in high temperature spaces to check the device's heat resistance

PHOTO: OPPO

The production of electronic circuit boards is carried out in the SMT Center, where the printed circuit boards are coated with solder paste, assembled by automated machines and subjected to optical, X-ray and RF tests. The devices are then transferred to the assembly shop for finishing, before entering the final tests for appearance and durability.

The overall system shows that modern smartphones today are evaluated for durability using many different layers of testing, from the material and component levels to the entire device and real-life usage scenarios. In the context of users carrying smartphones in many spaces and harsh climate conditions, durability standards are gradually being expanded beyond traditional certifications, reflecting the needs and risks in daily life.

Source: https://thanhnien.vn/kham-pha-quy-trinh-kiem-chung-do-ben-smartphone-cua-oppo-185251123204654222.htm

![[Photo] Cat Ba - Green island paradise](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F04%2F1764821844074_ndo_br_1-dcbthienduongxanh638-jpg.webp&w=3840&q=75)

![[VIMC 40 days of lightning speed] Da Nang Port: Unity - Lightning speed - Breakthrough to the finish line](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/04/1764833540882_cdn_4-12-25.jpeg)

Comment (0)