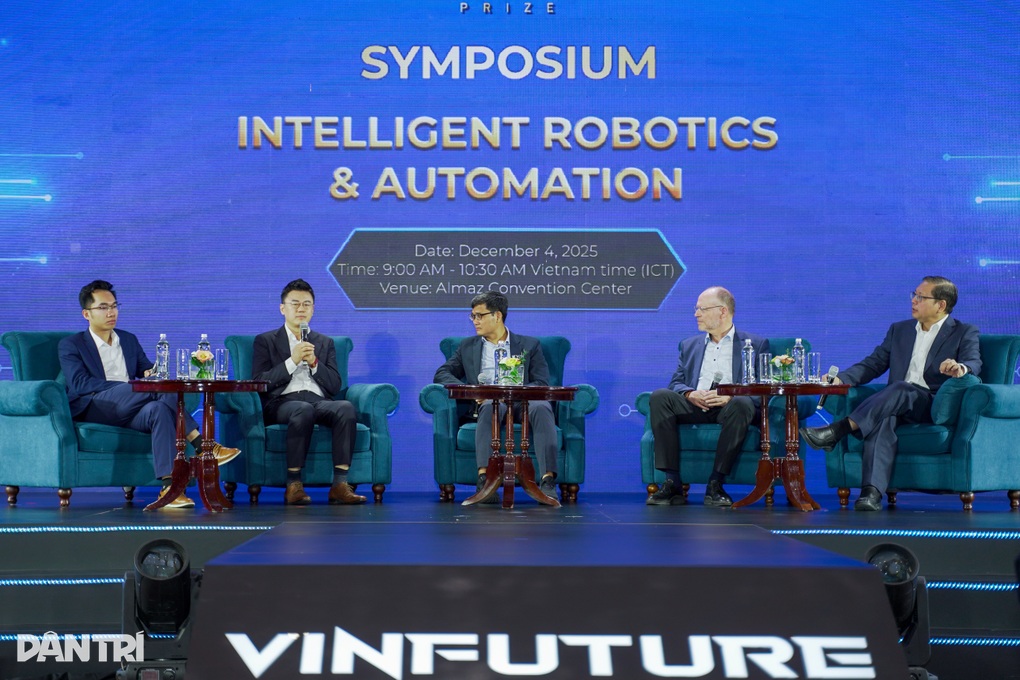

Professors shared at the seminar (Photo: Minh Nhat).

On December 4, within the framework of VinFuture Science and Technology Week, the seminar “Robots and Intelligent Automation” brought together many leading experts from around the world and Vietnam to discuss the trends shaping the future of robots.

Leading experts from around the world and Vietnam have painted a panoramic picture of the historic shift in the robotics industry: The combination of soft materials and artificial intelligence.

No longer rigid machines in industrial iron cages, robots are gradually becoming "softer", smarter and ready to enter human living spaces.

The "physical" revolution

For decades, robots have been synonymous with metal, rigid joints, and precision servo motors. But Professor Kurt Kremer opened the discussion with a completely different approach: Using soft materials like polymers to build robots.

Unlike silicon or metal, soft polymer materials have outstanding advantages: abundant supply, low cost, light weight and flexible structural transformation ability. The breakthrough lies in the "sensitivity" of the material.

"Soft polymer materials have the ability to respond reversibly and sensitively to external stimuli such as swelling in water, shrinking in alcohol or volume changes under the influence of electric/magnetic fields," shared Professor Kurt Kremer.

This allows for the creation of robots that are highly biomimetic, can safely interact with humans, and can perform delicate tasks that rigid robots cannot.

Professor Ho-Young Kim shares at the seminar on robotic materials (Photo: Minh Nhat).

However, Professor Ho-Young Kim pointed out that the biggest challenge of the era is controlling deformation.

Traditional industrial robots handle hard objects (auto parts) well because of their fixed shape. But soft materials such as fabrics and clothes, whose shapes constantly change, make robots "confused".

Scientists are focusing on improving the gripper to simulate human fingers and developing algorithms for robots to "perceive" material deformation, thereby manipulating it skillfully, such as picking up a T-shirt without wrinkling it.

While soft materials help robots become physically flexible, new-generation AI models are helping them transform their thinking. Professor Tan Yap Peng emphasizes the shift from "single-task" to "multi-task" robots.

In the past, engineers had to program each rigid line of code to fold laundry. Today, with the explosion of platform models like Gemini or OpenAI, we are witnessing the birth of models, languages, and actions.

Modern VLA robots (VLA: Vision-Language-Action) can understand the real world through cameras, understand natural human commands (e.g. “Please clear the table”) and convert the data into specific physical operations.

Thanks to VLA, future robots will be able to self-diagnose, self-repair, and act as a multi-purpose entity instead of a specialized machine.

Dr. Nguyen Trung Quan (Chairman of VinMotion) said that this is the pinnacle of convergence where AI escapes the computer screen to control a physical body in the real world.

Mr. Tran Minh Quan, Chairman of VinMotion (Photo: Minh Nhat).

This market is forecast to have great potential with a size that can reach 10,000 billion USD in the next decade. The main driving force comes from the severe global labor shortage.

According to Nvidia CEO, by the end of this decade, the world will be short of at least 50 million workers.

Experts say that while specialized robots are better suited for factories, humanoid robots are the best choice for residential environments.

Our world (staircases, doorknobs, work tools) is designed for humans; therefore, a humanoid robot would fit in easily and function most effectively.

Challenge

Dr. Quan pointed out the core challenge: To make robots smart, they need real data. But to release robots into the real world to collect data, they must be smart enough and safe enough.

The solution of pioneering companies like VinMotion is a roadmap approach: Collect data in the Lab - controlled testing - continuous improvement based on real-world errors.

In addition to the bright picture, at the roundtable discussion, experts also frankly acknowledged the major barriers. First, the treatment of waste from robots (polymers, batteries) is a difficult problem.

Professor Kurt Kremer suggests moving towards biodegradable materials, although they currently do not achieve the desired aesthetic durability.

Besides, the dream of robots with real artificial "muscles" is still far away. Currently, we are still at the stage of muscle simulation with motors and transmission systems, unable to reach the sophistication of biological muscle cells.

Many scientists and experts in the field of robotics attended the discussion (Photo: Minh Nhat).

Another concern is that as robots enter the elderly care and healthcare sectors, safety is paramount; both physical and algorithmic “safety cushions” are needed to prevent risks.

According to experts, with the advantage of young human resources, strong software platform and rising hardware production capacity, Vietnam can completely participate in this global "playground".

“Students need to have a solid grasp of basic knowledge but must have an open mind, and most importantly, they must get their hands dirty and work directly with robots to understand and master the technology,” Professor Kim shared.

Source: https://dantri.com.vn/khoa-hoc/thi-truong-10000-ty-usd-ky-nguyen-robot-buoc-ra-khoi-long-sat-20251204165352066.htm

![[Photo] Cat Ba - Green island paradise](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F04%2F1764821844074_ndo_br_1-dcbthienduongxanh638-jpg.webp&w=3840&q=75)

![[VIMC 40 days of lightning speed] Da Nang Port: Unity - Lightning speed - Breakthrough to the finish line](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/04/1764833540882_cdn_4-12-25.jpeg)

Comment (0)