From the “heart” of the Factory to the catalyst problem

In the operation process of Dung Quat Oil Refinery, the RFCC (Residue Fluid Catalytic Cracking) workshop is considered the "heart" of the entire system. This is where the process of converting heavy residue from crude oil distillation unit (CDU) into light products with high economic value such as gasoline, LPG, propylene, diesel oil and fuel oil takes place.

The Plant's RFCC consists of four workshops: reaction tower, catalyst regeneration system, product separation and gas-by-product treatment. With a design capacity of about 69,700 barrels/day, the RFCC can currently operate at over 110% capacity under optimal conditions - a testament to the technical, operational and continuous improvement capabilities of BSR's engineering team.

The core of the treatment process at RFCC is the catalyst - the decisive factor in the efficiency and quality of the product. The catalyst used is a fine powder zeolite, with an average size of 70 microns, operating in a "pseudo-fluidized bed" state to promote the cracking of long-chain components in heavy raw materials. The system always has about 600-650 tons of balanced catalyst, and every day needs to add 8-13 tons of new catalyst.

At the same time, the amount of waste catalyst is almost equal to the amount of newly added catalyst, averaging 10 tons/day. This catalyst is collected at specialized locations such as Hopper D-1506 and Silo Fine, then classified and processed according to national standards QCVN 07:2009/BTNMT on hazardous waste threshold. Since the Plant has been in operation, samples of RFCC waste catalyst have been sent to the appraisal unit for analysis, and the results have all met the requirements - below the hazardous waste threshold.

However, on March 21, 2023, the inspection unit provided the results of arsenic (As) in the catalyst batch dated February 24, 2023 as 8.05 mg/L, exceeding the normal waste threshold of 2 mg/L. If these results are confirmed, this RFCC catalyst batch will have to be classified and treated as hazardous waste - resulting in a sudden increase in costs: from VND 736,000/ton to VND 4.6 million/ton.

Faced with such “abnormal” results, upon receiving the assigned task, the Laboratory engineers re-analyzed all raw materials, chemicals, and processing additives at the RFCC workshop to trace the source of As accumulated on the above catalyst batch. The re-evaluation results showed that no source had a large enough arsenic content to accumulate to a level exceeding the threshold in the catalyst. This raised the initial conclusion: the service unit’s analysis method may be interfered with, causing positive errors in the test results.

When BSR engineers "diagnose" and find solutions themselves

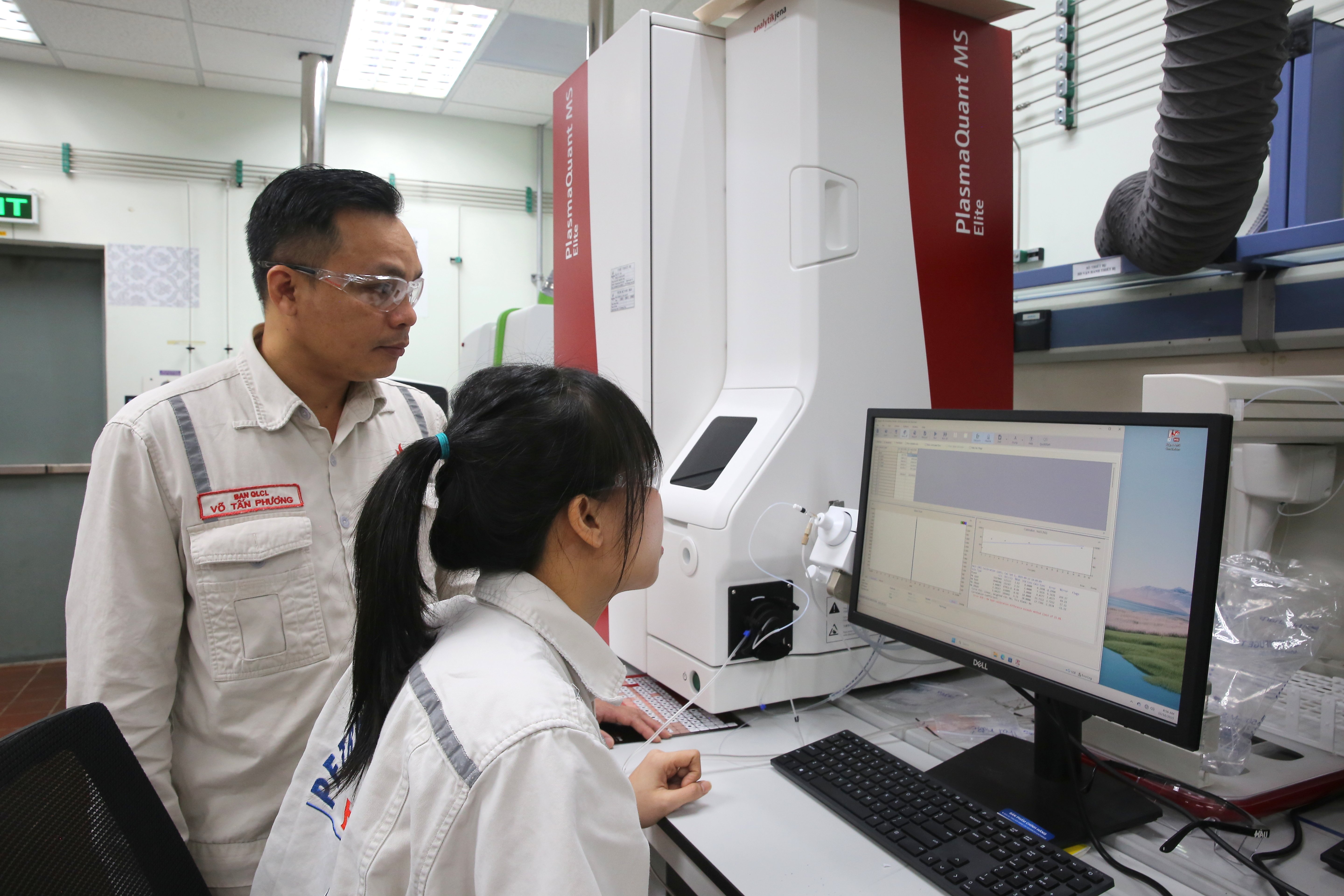

Faced with that reality, the BSR Laboratory engineering team - headed by engineer Vo Tan Phuong - embarked on a research and development of an internal analysis method to completely replace outsourcing. This is a task that not only requires in-depth knowledge of analytical chemistry but also requires a deep understanding of the RFCC technological process.

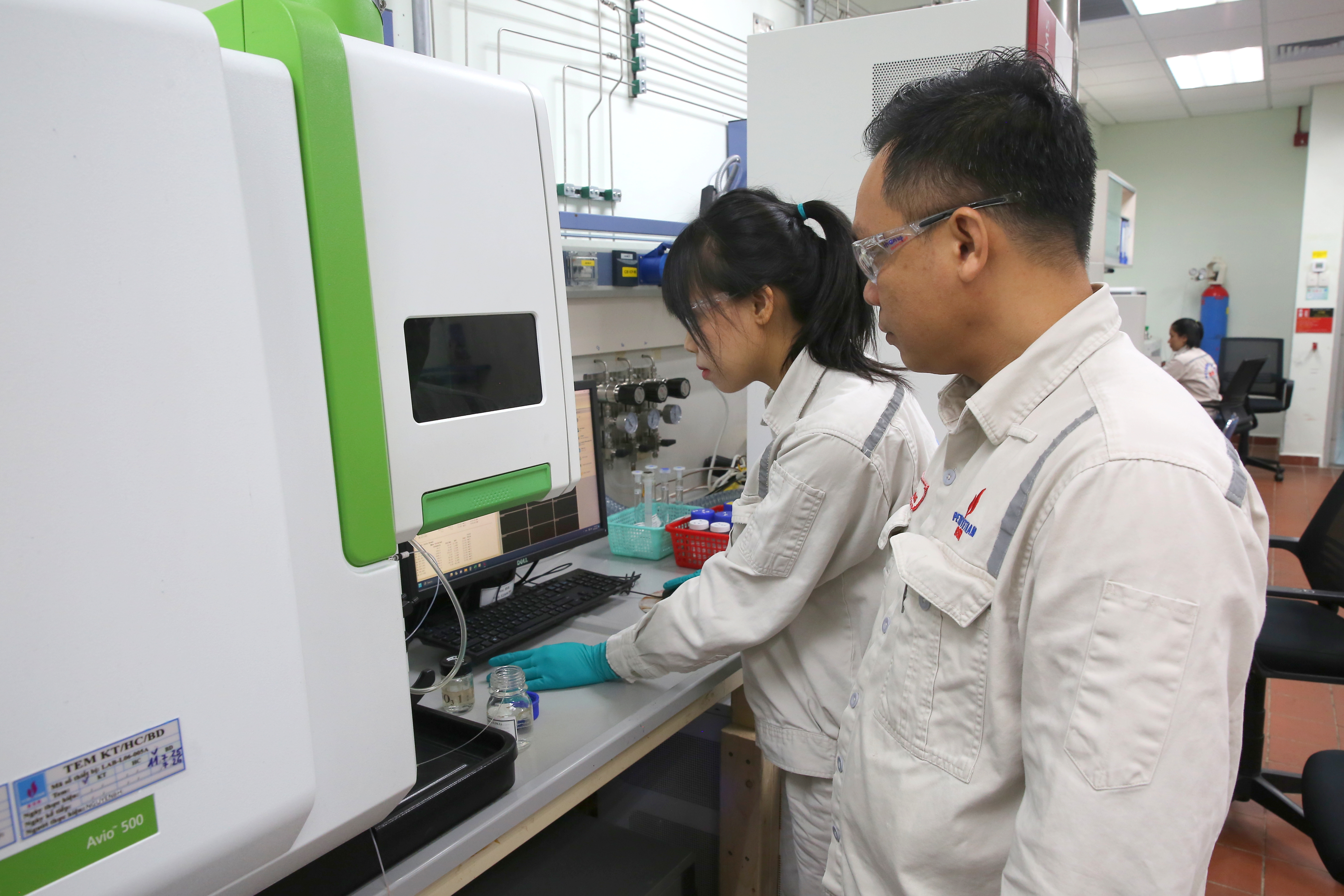

According to the original design, BSR Laboratory did not have the function of analyzing extracted metal indicators such as arsenic and antimony in catalysts. However, in response to urgent requirements, the engineering team proactively took advantage of existing equipment - especially the ICP-OES machine and rotary evaporator - to re-establish the entire metal extraction process according to EPA 200.7 & 1311 standards, but "localized" to suit actual conditions.

This innovative solution has completely replaced expensive specialized equipment with an available rotary evaporator, helping to effectively extract metals in the catalyst into the water phase. In particular, the research team discovered that interference from the rare earth element Lanthanum (La) - which appears in zeolite catalysts - is the main cause of incorrect arsenic results. From there, the team conducted many experiments, built a solution to handle interference factors, ensuring high accuracy when analyzing on ICP-OES equipment at wavelengths of 193nm and 197nm.

This “homegrown” solution not only helps increase the accuracy of the analysis results but also fully meets the technical requirements of the ISO 17025 standard. The results are impressive, when applying the new method with highly accurate test results, the retested RFCC catalyst samples are all within the safety limit, below the threshold of hazardous waste. In particular, the group of authors cooperated to transfer the solution to the appraisal unit to re-analyze the above catalyst batch.

After applying BSR's recommendations, the testing unit re-delivered the catalyst batch analysis results on February 24, 2023, and this time, the arsenic content was lower than the prescribed threshold, confirming the correctness and practical value of the initiative.

The initiative “Improving the method of analyzing arsenic and antimony (EPA 200.7 & 1311) in RFCC catalysts to increase the accuracy of test results” won the first prize of the 14th Quang Ngai Province Technical Innovation Contest (2024-2025). In terms of technology and environment, the new method helps BSR Laboratory to be completely proactive in controlling catalyst quality, calculating and adjusting the dosage of Ni passivator chemicals, and accurately classifying waste catalysts according to QCVN 07:2009/BTNMT regulations, ensuring compliance with the law and optimizing waste treatment costs.

Economically, the benefits are even more obvious. Previously, each year the BSR Laboratory had to send about 208 waste catalyst samples to the outside, at an average cost of 5.28 million VND/sample. When doing it in-house, the cost is only 313,033 VND/sample. Thus, each year BSR saves about 1.033 billion VND - not to mention the indirect benefits from being proactive and quick in quality control and technology adjustment.

Mr. Pham Cong Nguyen - Head of BSR Quality Safety Department commented: “ Looking back at the whole journey, this initiative is not just a story about a test or a small technical step. Behind it is the spirit of creativity, initiative and science - values that are deeply ingrained in BSR's innovation culture.

From detecting abnormal signs, to the process of “diagnosing”, analyzing, finding the cause, and then building a complete alternative method, BSR engineers have demonstrated their ability to master technology and unlimited creativity. They not only handle a specific technical problem but also contribute to reducing costs, improving sustainability in production, and affirming the spirit of “BSR people” - talk less , think more , do more, fast speed, high efficiency.

With intelligence and enthusiasm, BSR Laboratory engineers have turned seemingly small operations into solutions that bring benefits of more than 1 billion VND per year. This story once again affirms: at Dung Quat Oil Refinery, every initiative and improvement, whether at the laboratory scale or the production process, is a small brick that builds great value for the enterprise and for the energy and petrochemical industry in Vietnam.

Duc Chinh

Source: https://bsr.com.vn/web/bsr/-/cai-tien-phuong-phuong-phap-phan-tich-phong-thi-nghiem-ky-su-bsr-lam-loi-hon-1-billion-dong-moi-nam

![[Photo] Parade to celebrate the 50th anniversary of Laos' National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764691918289_ndo_br_0-jpg.webp&w=3840&q=75)

Comment (0)