To minimize the impact on the surrounding environment during the production process, Quang Ninh Cement and Construction Joint Stock Company has implemented many effective solutions. This is one of the cement production units that the Department of Natural Resources and Environment has evaluated as having many good initiatives in environmental protection…

According to the initial design from 2007-2009, Lam Thach Cement Plant (Quang Ninh Cement and Construction Joint Stock Company) used electrostatic precipitators (in the clinker kiln stage of the two production lines). However, due to dependence on the national power grid, if a power outage occurs during operation, the plant's electrostatic precipitator system will suddenly stop working, causing high-altitude dust generation.

To address this issue, from 2020 to the present, the company has renovated and upgraded the systems of its two production lines with a total investment of over 357 billion VND. Of this, 70 billion VND has been invested in renovating and converting two electrostatic precipitator systems to fabric bag filters. The company has also invested in and put into operation two NOx removal systems for the two kiln lines to treat exhaust gases generated at the kiln chimneys. Putting these systems into operation has helped the company overcome power grid problems and completely eliminate dust generation affecting the surrounding environment.

In November 2020, the company completed the installation of an automated emission monitoring system with a total investment of VND 12.5 billion. The monitoring system is installed at various locations, including: clinker kiln chimneys; clinker cooling areas; cement grinding plants; and coal grinding plants. Monitoring results for dust and emissions are continuously updated (every 5 minutes) and transmitted to the Department of Natural Resources and Environment for 24/7 monitoring, enabling the factory to effectively control dust and emissions levels, and quickly detect and address incidents during production.

Aiming to develop production according to a circular economy model, in April 2022, Quang Ninh Cement and Construction Joint Stock Company launched the initiative to maintain the "Waste Bank - Deposit Waste, Withdraw Money" model. This is the first "Waste ATM" model implemented at a cement factory in Vietnam. Each kilogram of waste is equivalent to 1 point, converted into money ranging from 3,000 to 11,000 VND depending on the type of waste. Each person who deposits waste is given an account by the company to manage all waste deposit data. When the account reaches 300 accumulated points and the account holder has not withdrawn money, the company will pay interest at 1% per year. To attract more people to participate in the "Waste ATM," the company offers many attractive programs, such as: providing home delivery, purchasing waste at prices 10-15% higher than market prices, and subsidizing interest for long-term accumulated accounts…

After more than a year of operating the "waste ATM," the company has collected 120,000 tons of recyclable waste, spreading environmental protection initiatives. According to the Department of Natural Resources and Environment, maintaining this model also benefits from raising awareness and encouraging local residents to care about and participate in environmental protection through waste sorting, recycling, and transforming waste into resources.

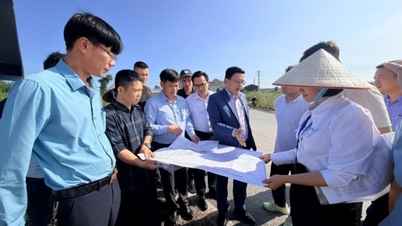

In August 2020, Quang Ninh Cement and Construction Joint Stock Company and the People's Committee of Phuong Nam Ward (Uong Bi City) signed a cooperation agreement on effectively implementing environmental protection, security, order, and social welfare work for the period 2020-2025. Accordingly, Phuong Nam Ward established and strengthened the Environmental Monitoring Team. The Monitoring Team is tasked with continuously monitoring and supervising the environmental protection work of Lam Thach Cement Plant 24/7; and reporting information to the People's Committee of the ward. From 2020 to the end of June 2023, the Environmental Monitoring Team conducted 11 inspections related to environmental work at the plant.

Ms. Vu Thi Thuan, residing in Hop Thanh area, Phuong Nam ward (Uong Bi city), stated: "Recently, Lam Thach Cement Plant has proactively implemented many solutions to improve the environment. The plant has invested in many environmental projects, including planting trees, spraying mist to suppress dust, and maintaining a 'garbage ATM' model... In addition, close cooperation between the local government and the enterprise has created transparency in information related to the plant's environmental activities. Upon receiving any feedback from residents regarding environmental issues, the monitoring team verifies the cause, draws up a report, and the plant promptly rectifies the problem."

Mr. Vu Trong Hiet, Deputy Director of Quang Ninh Cement and Construction Joint Stock Company, said: Quang Ninh Cement and Construction Joint Stock Company continues to closely coordinate with Phuong Nam ward in building welfare facilities and urban environmental beautification projects at some key locations in the ward; proactively coordinate in managing and controlling all production activities of the factory, minimizing incidents affecting environmental sanitation; and ensuring state management of the environment in the area. At the same time, it coordinates in preparing and adjusting planning to serve production and business, supporting land clearance, and maintaining and developing the "Garbage Bank - Deposit Garbage, Withdraw Money" model in residential areas throughout Uong Bi.

Source

![[Photo] Prime Minister Pham Minh Chinh holds a phone call with the CEO of Russia's Rosatom Corporation.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765464552365_dsc-5295-jpg.webp&w=3840&q=75)

![[Photo] Closing Ceremony of the 10th Session of the 15th National Assembly](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765448959967_image-1437-jpg.webp&w=3840&q=75)

![[OFFICIAL] MISA GROUP ANNOUNCES ITS PIONEERING BRAND POSITIONING IN BUILDING AGENTIC AI FOR BUSINESSES, HOUSEHOLDS, AND THE GOVERNMENT](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/11/1765444754256_agentic-ai_postfb-scaled.png)

Comment (0)