|

| The ventilation test at Unit 1, which took place in late November, was a great success. |

Finish quickly but surely

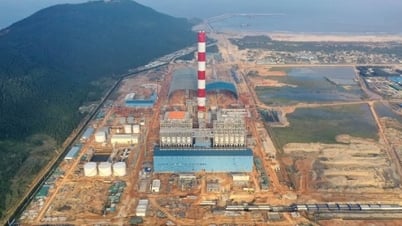

According to the Power Project Management Board 2 (EVNPMB2), up to now, the total progress of the project has reached a very high level, many key packages have been completed. The first oil firing for the boiler of Unit 1 has been successfully carried out - a key turning point to move to the synchronous test run phase.

“We are racing against time,” said Nguyen Minh Hoang, Deputy Director of the Project Management Board. “Most of the auxiliary systems – from water treatment, compressed air, lubricating oil to cooling systems – have been tested and are stable. The December 19 deadline is not just a deadline, but also a commitment from thousands of people working day and night on the construction site.”

The harsh weather has caused many obstacles to the construction work. The prolonged rains have made the ground slippery, and many installation items have had to be adjusted. However, instead of slowing down the progress, the team of engineers and workers have organized to work in shifts, setting up camps near the construction site to ensure there is no "interruption" in time.

|

| Domestic contractors are undertaking the construction of many important items of the project. |

Representatives of contractors Lilama 10 and Lilama 18, the units in charge of most of the mechanical and installation work, shared that their level of determination is not inferior to that of the investor.

Mr. Pham The Thao , Commander of Lilama 18 construction site, said: “Our construction volume is up to 68,000 tons of equipment. Up to now, more than 88% has been completed. The rain and wind made the installation of boilers, turbines, dust filtration systems... much more difficult, but we determined: once we have accepted the task, we must finish on time.”

At many times, the number of workers on the construction site exceeded 4,000 people. Support teams, such as Mr. Trinh Quang Tuyen's unit (Lilama 10), had to stay on site 24/7. Mr. Tuyen said: "To keep up with the progress, we arranged for continuous staff, and food and accommodation were prepared right at the construction site. With the responsibility of a Vietnamese contractor in a national-scale project, we have to do better every day."

With the combined efforts from the investor to the contractor, Quang Trach I is gradually realizing the goal of becoming one of EVN's fastest, safest and most synchronously completed thermal power projects in recent years.

|

| The coal storage area is designed with cover to reduce dust. |

Supercritical technology and green standards

One of the factors that makes Quang Trach I considered by experts as a "technological step forward" in Vietnam's thermal power industry is the application of the most modern Ultra Supercritical (USC) technology today.

The plant's boiler operates under very high pressure and temperature conditions, thereby increasing energy conversion efficiency, helping to reduce coal consumption to about 280g/kWh, significantly reducing CO₂, SOx, NOx emissions.

EVNPMB2 representative affirmed: “We optimize technology not only to increase operational efficiency, but also to fully meet domestic and international environmental standards.”

The factory is equipped with: FGD desulfurization system; NOx emission reduction system; High-performance ESP electrostatic precipitator; CEMS automatic emission monitoring technology.

Thanks to that, the exhaust gas before going out the chimney meets strict environmental standards, and is considered one of the most advanced treatment lines in coal-fired thermal power plants in Vietnam.

A notable point is that the participation rate of Vietnamese enterprises in construction is very high: Lilama, CC1 and many domestic mechanical units undertake important items. This localization not only helps save costs but also enhances the autonomy of the Vietnamese mechanical and energy industry.

Quang Trach I Thermal Power Plant not only helps supplement an important source of electricity for the Central region - an area with a large capacity shortage, but also creates a balance for the national power system, especially in the context of a rapidly increasing but unstable proportion of renewable energy.

According to the assessment from the Ministry of Industry and Trade and EVN, when put into operation, Quang Trach I will provide 8.4 - 9 billion kWh of electricity per year; reduce the load on the North - Central transmission system; create additional budget revenue and long-term jobs for the locality.

Notably, in the long-term design, the plant has calculated the possibility of converting fuel to biomass or ammonia to suit Vietnam's Net Zero 2050 roadmap. This shows that the project not only serves the immediate needs but also prepares for the future of clean energy transition.

Quang Trach I Thermal Power Plant Project has a total investment of about 41,000 - 42,000 billion VND; designed capacity of 1,200-1,403 MW, including 2 units, expected to provide electricity output of about 9 billion kWh/year.

The EPC contractor is a consortium of Mitsubishi Corporation (Japan) - Hyundai E&C (Korea) - CC1 (Vietnam).

The project is located in Quang Trach Power Center, an area where LNG projects are expected to be deployed in the next phase, aiming to form a synchronous electricity-gas complex for the North Central region.

Source: https://baodautu.vn/nha-may-nhet-dien-quang-trach-i-tang-toc-ve-dich-voi-quyet-tam-hoan-thanh-dung-tien-do-d451873.html

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764951162416_2628509768338816493-6995-jpg.webp&w=3840&q=75)

![[Photo] 60th Anniversary of the Founding of the Vietnam Association of Photographic Artists](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764935864512_a1-bnd-0841-9740-jpg.webp&w=3840&q=75)

Comment (0)