In recent years, facing complex and volatile geological conditions, with the -100 meter level mining area entering its final stages, Duong Huy Coal Company has been simultaneously carrying out production and implementing expansion projects down to the -250 meter level. To overcome these difficulties, Duong Huy Coal Company has identified its most important strategy as mechanization, automation, computerization, and ultimately the digitalization of all aspects of production and management.

The company has also gradually implemented synchronized mechanization to open up, connect, and improve the transportation system in the mine and on the surface. Specifically, it regularly trims and renovates the entire main cross-seam tunnel, the -100 level and +38 level stations, and many other tunnels to ensure large cross-sections; it has invested in a series of modern transportation equipment such as pneumatic monorail systems, diesel monorail systems, curved conveyors, hydraulic chain and cable-type mine trolley systems, etc., to enhance transportation capacity, meet the requirements of high production throughput, reduce manual labor, and significantly increase productivity.

In tunnel excavation, the unit maintains two semi-mechanized tunneling faces using drilling rigs and excavators; puts the EBH-45 tunnel boring machine into operation; and actively applies other modern technologies such as hydraulic and pneumatic anchor drilling machines, anchor drilling robots, etc., to excavate tunnels under suitable geological conditions. In underground coal mining, the company operates 11 longwall mining systems simultaneously, applying advanced support technology, including two synchronized medium and light-duty mechanized longwall mining systems, along with flexible support systems, chain supports, and modular frames; maintaining and expanding the network of cameras, mine gas monitoring equipment, coal quality monitoring, and timekeeping and payroll software to ensure transparency of income.

Recently, to meet the requirements of the mechanization and automation strategy in production, two tunneling workshops have been transformed. Tunneling Workshop 1 has been converted into a fully mechanized tunneling workshop, managing and operating fully mechanized equipment in tunneling, such as the Combai EBH-45 tunneling machine and other fully mechanized tunneling machines. Tunneling Workshop 2 has been converted into a semi-mechanized tunneling workshop, responsible for tunneling work with semi-mechanized equipment such as drilling rigs and excavators. This is a new breakthrough in the corporate management of Duong Huy Coal Company, simultaneously synchronizing equipment management, aligning with the requirements for a streamlined production equipment system, and sustainably improving the skills of workers and employees, thereby enhancing the efficiency of tunneling work and meeting the company's future deep tunneling requirements.

In addition, the company regularly organizes short-term training courses on career chuyển đổi (career retraining) and technology transfer when the structure of the mine workings and tunnel excavation technology change; courses on managing, using, repairing, and operating mining equipment; professional training in electromechanical engineering, bridging from basic to intermediate mining; and training courses for production supervisors at the site and workshop levels... Through these, the company ensures a high-quality workforce to serve the goals of mechanization and sustainable development for the unit in the coming years.

Recently, the company organized a professional skills test for its entire economic staff. Thirty employees from various workshops underwent two parts of the test: a multiple-choice test and a direct oral examination by a panel of judges consisting of members of the leadership team and heads of specialized departments. The test focused on key areas such as cost management, labor policies, the application of Esoft software in human resource management, materials and equipment management, and the updating and implementation of company directives…

According to Mr. Cao Viet Phuong, Acting Director of the Company, investing in the quality of the workforce, especially those working in the economic departments of the workshops, is not only an internal requirement but also a crucial condition for strengthening corporate governance. This is not merely a competency assessment, but a basis for shaping training and professional development programs, serving the strategy of informatization towards comprehensive digitalization of production, aiming for the sustainable development of the Company in the era of Industry 4.0.

With continuous efforts, Than Duong Huy successfully completed its tasks for the first six months of 2025. Most economic and technical indicators exceeded the planned targets. The company maintained its safety standards in production and took good care of its employees, with an average income of nearly 24 million VND per person per month. This serves as a foundation for the company to continue striving towards the goal of "Green mine, modern mine, high-production mine, high-income mine, safe mine".

Source: https://baoquangninh.vn/than-duong-huy-day-manh-3-hoa-de-but-pha-3365473.html

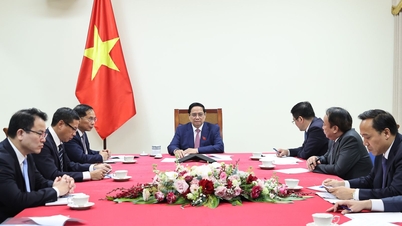

![[Photo] Prime Minister Pham Minh Chinh holds a phone call with the CEO of Russia's Rosatom Corporation.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765464552365_dsc-5295-jpg.webp&w=3840&q=75)

![[Photo] Closing Ceremony of the 10th Session of the 15th National Assembly](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765448959967_image-1437-jpg.webp&w=3840&q=75)

![[OFFICIAL] MISA GROUP ANNOUNCES ITS PIONEERING BRAND POSITIONING IN BUILDING AGENTIC AI FOR BUSINESSES, HOUSEHOLDS, AND THE GOVERNMENT](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/11/1765444754256_agentic-ai_postfb-scaled.png)

Comment (0)