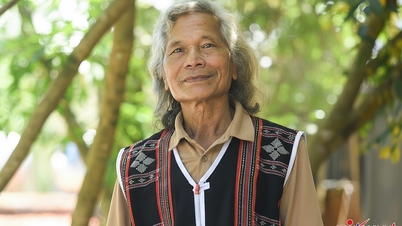

From the simple question, "Is there a machine that can help us reduce our workload?", Dr. Nguyen Huu Chuc, from Hue Industrial College, began his journey to create a semi-automatic vegetable harvesting machine, a device that can increase productivity 10-15 times, while harvesters only need to... walk.

In leafy vegetable production, an industry with export value exceeding $3.3 billion in 2022, harvesting accounts for up to 40% of the workload. For a long time, Vietnamese farmers have relied primarily on manual cutting methods, which are time-consuming, labor-intensive, and result in a low level of mechanization in vegetable production. Although many types of vegetable harvesting machines have been developed worldwide , most are expensive and unsuitable for the small, scattered vegetable fields typical of Vietnam. Therefore, Dr. Chuc and his colleagues set out to create a simpler, cheaper machine that is suitable for domestic farming conditions.

Starting from a provincial-level research project in 2015, the research team began surveying harvesting technologies on the market. They found that handheld harvesters in Vietnam still required farmers to bend over while working, and larger imported machines were only suitable for large-scale farms.

Abroad, especially in China, walking or rail-operated harvesting machines have appeared, some even equipped with electronic sensors to adjust cutting height. However, upon closer examination, Dr. Chuc discovered that many designs cause vegetables to be bruised, lack mechanisms for sorting wilted vegetables, or cannot adjust the length of the vegetable stems after cutting... all of which directly affect quality and selling price.

The research team began designing a harvesting system suitable for Vietnamese vegetable fields, featuring a lightweight frame, a cutting unit using thin saw blades to avoid crushing the leaves, rollers to transport the vegetables onto a conveyor belt, and a rear collection chamber for storage. To adjust the length of the vegetable stems after cutting, an integrated distance sensor helps determine the saw blade position according to the type of vegetable.

The biggest challenge lies in the sorting of wilted vegetables and weeds. The team experimented with combining image recognition cameras and robotic arms to remove impurities directly from the conveyor belt. Laboratory results were promising, but in the field, vibrations, changing lighting, and uneven terrain significantly reduced accuracy. To perfect the recognition technology, the team needs to expand the image data and optimize the model, which is currently beyond their budget.

Nevertheless, Dr. Chuc's semi-automatic harvesting machine has achieved outstanding efficiency. While a worker can only harvest 50-70 kg of water spinach per day, the device can achieve a maximum of 100 kg/hour. Thanks to its novelty and high applicability, the machine was granted a utility model protection certificate by the Intellectual Property Office in September 2022.

Unlike many scientists who often downplay the importance of intellectual property registration, Dr. Chuc places great emphasis on this process. He believes that protection not only safeguards research but also helps businesses become aware of the product, paving the way for commercialization. In fact, the demand for vegetable harvesting machines in Vietnam is huge, and whenever a video of a harvesting machine appears online, the comments section is flooded with questions like "where to buy one?".

Although the device has received initial orders, mass production still faces many obstacles. Each locality has different plot sizes, requiring the machine to be customized to specific requirements, making it difficult to create a standardized version. This drives the cost up to over ten million dong, an investment that not all farmers are willing to make, despite its proven harvesting efficiency.

Although there is still a long way to go before commercialization, Dr. Nguyen Huu Chuc's semi-automatic vegetable harvesting machine demonstrates the enormous potential of science and technology in solving small but practical problems for farmers. More importantly, it proves that innovation doesn't necessarily have to come from large laboratories, but sometimes begins with a very ordinary question amidst the sun-drenched fields: "Is there a way to make life easier for farmers?"

Source: https://mst.gov.vn/may-thu-hoach-rau-ban-tu-dong-giai-phap-tu-phong-thi-nghiem-giup-nong-dan-dung-thang-197251211142144423.htm

![[Photo] Closing Ceremony of the 10th Session of the 15th National Assembly](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765448959967_image-1437-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh holds a phone call with the CEO of Russia's Rosatom Corporation.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765464552365_dsc-5295-jpg.webp&w=3840&q=75)

![[OFFICIAL] MISA GROUP ANNOUNCES ITS PIONEERING BRAND POSITIONING IN BUILDING AGENTIC AI FOR BUSINESSES, HOUSEHOLDS, AND THE GOVERNMENT](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/11/1765444754256_agentic-ai_postfb-scaled.png)

Comment (0)