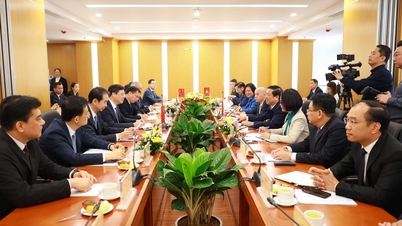

Introducing to visitors the exhibition and honor space at "House of the Guangxi Master of Skills" - Photo: TRONG NHAN

'Guangxi Skill Master's House' is an exhibition and exchange space built by the Guangxi Department of Human Resources and Social Security (China), honoring skilled workers and technical experts who have made outstanding contributions to local industry.

The house is a gathering place for national and autonomous region-level "skill masters", displaying industrial products, professional tools, certificates of merit and technical innovations.

Honoring outstanding contributions

Each name on the wall of honor is solemnly presented. Huang Dewen is an electrical skills expert from Guangxi Steel Corporation who won the title of "National Technical Master". Zheng Zhiming of Guangxi Automobile Corporation won the "China Skills" award and is a master of automobile engineering. Wu Liuning from Liuzhou Dongfeng Factory is a "National Technical Master" in the electrical industry and is described as "capable of handling difficult technical errors that are not easily recognized by machines"...

In China, there is a whole hierarchy of titles for skilled workers. The pinnacle is the “China Skills” award, which is given out every two years by the Ministry of Human Resources and Social Security and is considered the academician of the workers.

Next is the title "National Technical Skilled Worker" also selected periodically by this ministry, each time a few hundred people are honored to honor high-level workers with excellent skills.

The "China Skills" Award was established in 1995. Initially, only 10 grand prize winners and 100 "National Technical Talents" were selected each year. Since 1998, the selection has been held every two years and then expanded to include collective categories for units with outstanding contributions to cultivating skilled talents.

The award ceremony was also held on a large scale, presenting medals, trophies, certificates and cash prizes to those who won the title of "Chinese Skills". Those who were awarded the title of "National Technical Talent" also received medals, certificates of merit and were widely promoted in the media.

For example, Guangdong province also provides funding to set up a national-level master skills office for those who have achieved the title. Thereby, it increases their income, professional status and creates conditions for them to lead new technology projects.

Can learn how to do a trade, learn a trade

This model and approach more or less allows us to learn from experience, such as building national skill titles with clear messages, transparent criteria, solemn honors and directly linking the titles with income benefits, career positions, training opportunities or ordering mechanisms between businesses and schools.

When a welder, electrician or mechanical technician can become "person of the year", the image of engineering in the eyes of parents and students may change more dramatically than any career counseling program.

China's narrative of the "skill master," the young craftsman who rises from the factory floor to become a national expert, seems to tap into three factors: prestige, career prospects, and social recognition.

When career models are narrated as success journeys, the profession is no longer a stopgap but a path with a clear future. Indeed, the impact of vocational education on industrialization has been well demonstrated in many successfully industrialized countries.

In Germany, the dual training model combining 70% of practical time at the enterprise and 30% of theory helps this country continuously maintain a stable force of highly skilled technicians and workers. It is this team that operates precision mechanical production lines from Bosch, Siemens to BMW...

Or in Korea, the breakthrough period from 1970 to 1990 was closely linked to the explosive development of vocational schools. When they were determined to build heavy industry, they established a series of technical schools directly linked to the "chaebol". Hyundai took students from Ulsan Automotive Vocational School, Samsung trained semiconductor technicians from Daedeok Technical College. As a result, Korea entered the group of leading electronics, shipbuilding and automobile manufacturing countries in the world .

Japan has a similar story. Since the Meiji period, the country has built a system of vocational schools and networks of artisans to ensure that each new industry has a skilled workforce. Corporations such as Toyota, Hitachi and Mitsubishi still maintain the "takumi" system, or master craftsmen who are considered the soul of the production line.

Increasing the attractiveness of vocational education

Below the national level, provinces and autonomous regions in China also establish titles: master skills, provincial-level chief skills, and within enterprises there are "chief engineers". Meanwhile, at the school level, there is a nationwide network of vocational competitions to help discover and nurture young talents.

According to leaders of many vocational colleges in Guangxi, this title system is a piece in the strategy of building a team of knowledgeable, skilled and creative workers, closely linked to skill improvement programs.

Those who are awarded the title often become the core of technical innovation, digitization of production lines, taking on the role of mentoring and training, contributing to improving the quality of technical human resources of enterprises.

Socially, the formal recognition and display of portraits of “skill masters” in factories and exhibition centers helps to raise the status of workers in the eyes of the public. The campaign to honor skilled workers is an important lever to increase the attractiveness of vocational education.

Source: https://tuoitre.vn/cach-trung-quoc-nang-nguoi-tho-len-thanh-linh-hon-cua-cong-nghiep-doi-moi-20251205083100836.htm

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764951162416_2628509768338816493-6995-jpg.webp&w=3840&q=75)

![[Photo] 60th Anniversary of the Founding of the Vietnam Association of Photographic Artists](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764935864512_a1-bnd-0841-9740-jpg.webp&w=3840&q=75)

Comment (0)