According to experts, in order to maintain their market share, businesses in the mechanical engineering industry need to improve their competitiveness and proactively adapt to the supply chain.

Promote localization and increase the proportion of domestic production.

Assessing the current state of the mechanical engineering industry, economist Dinh Trong Thinh said that in recent times, with support from the Government and ministries, associations, and the efforts of businesses, the mechanical engineering industry has seen positive changes.

Accordingly, Vietnam's mechanical engineering sector currently has strengths concentrated in three main sub-sectors: motorcycles and motorcycle parts and components; household appliances and tools; and automobiles and automobile parts. The domestic mechanical engineering, machinery, and equipment industry has gradually mastered and increased the localization rate, creating momentum to promote the development of other industries and the economy, thereby directly and indirectly creating jobs for millions of workers.

Currently, domestic mechanical engineering and manufacturing can produce and assemble most types of passenger cars, trucks, and buses; motorcycle production has a localization rate of 85-95%, meeting domestic demand and export needs. Among these, some typical enterprises in the automotive sector include Vinfast, Thanh Cong, and Thaco …

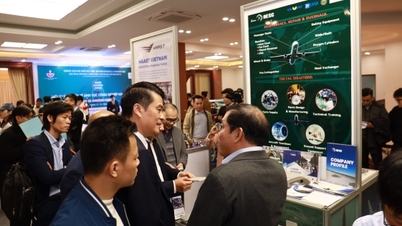

|

Many products from Intech Mechanical were displayed at the 5th Vietnam International Exhibition on Supporting Industries and Manufacturing (VIMEXPO) 2024. Photo: D.N. |

However, according to expert Dinh Trong Thinh, it must also be acknowledged that, despite numerous support policies, Vietnam's mechanical engineering industry still primarily focuses on producing components, household goods, tools, and spare parts for automobiles. Domestically produced mechanical products currently account for only about 7% of the market.

Meanwhile, many mechanical products require high technology, which domestic businesses are unable to produce. Furthermore, diversifying and expanding markets remains extremely difficult for businesses in the mechanical engineering industry due to fierce competition from foreign companies.

According to expert Dinh Trong Thinh, to meet domestic demand, the machinery and equipment industry needs to promote localization and increase the proportion of domestic production. This requires domestic enterprises to invest in research and development, improve production capacity, and meet the high technical and quality standards of the market.

"In particular, to maintain their market share, businesses need to enhance their competitiveness. At the same time, businesses need to take advantage of the opportunities arising from existing free trade agreements to seek new opportunities," expert Thinh said.

Regarding the industry's potential, according to forecasts by the Vietnam Association of Mechanical Enterprises (VAMI), the domestic machinery market demand could reach US$310 billion by 2030, but this largely depends on imports. Therefore, VAMI believes that to seize this opportunity, Vietnamese businesses need to strive to develop and meet market demands.

Proactive supply chain adaptation

Recognizing that adaptability is a key factor in entering the supply chain, many businesses in the mechanical engineering industry have innovated and seized opportunities for development. In an interview with the Industry and Trade Newspaper regarding the company's market expansion plans, Mr. Vuong Phuc Ha – representative of Vietnam Industrial Technology Group Joint Stock Company (Intech Group) – stated: To seize development opportunities, the company has continuously innovated and improved product quality to meet market demands. In particular, the strategy of diversifying products and customer segments has brought stable revenue to the business. Currently, 70% of the company's revenue comes from domestic customers, and the remaining 30% comes from export markets, with the Japanese market accounting for a large proportion.

To meet the high quality standards of Japanese customers, Mr. Ha said: The company is focusing on improving the production process from raw material import to processing, assembly, and product finishing. Accordingly, the company has invested in a product quality control system, with approximately 90% of products being inspected before delivery to customers.

|

With their market responsiveness, domestic businesses are fully capable of producing products for the global value chain, replacing many imported products. Photo: D.N. |

"Regarding market expansion, the company representative stated that the company is collaborating with partners such as Bitexco and trading companies to expand its domestic and international markets. Along with responding to market fluctuations, the company places special emphasis on technological innovation, moving towards automation, and prioritizing product quality," said Mr. Vuong Phuc Ha.

In addition to committing to promoting energy-saving solutions and sustainable development in the mechanical engineering, automation, technology, and green energy industries through the application of advanced solutions in production operations, according to Mr. Ha, in 2025, Intech Group aims to export products and services internationally; create an international standard working environment; ensure international standard product and service quality; and participate extensively in the global supply chain, bringing Vietnamese brands to the world stage with high-quality products and professional services.

Also a business that adapts quickly to the market, Mr. Nguyen Hong Phong, Chairman of the Board of Directors of AN MI TOOLS Co., Ltd., said that the stringent requirements from foreign direct investment (FDI) enterprises when investing in production and seeking distributors in Vietnam have forced Vietnamese mechanical engineering businesses to adapt.

Accordingly, Mr. Phong stated that AN MI TOOLS has strived to seek FDI customers and cooperate with leading global companies in cutting tools, measuring equipment, machinery, and machine accessories to supply the domestic market. As a result, the company has become the representative of Dormer & Pramet in Vietnam and a strategic partner of 21C Company (Korea).

Following development trends, AN MI TOOLS has invested in a series of high-tech production machinery from leading global manufacturers to enhance the competitiveness of its products. The company aims for revenue of VND 750 billion in 2025, VND 1,000 billion in 2026, and VND 1,500 billion in 2027.

With market responsiveness, domestic businesses have demonstrated their ability to produce products for the global value chain, replacing many imported products. Sharing his views on this matter, Mr. Nguyen Van Ket, Director of SKD Vietnam Precision Engineering Company, stated that domestic products are now in no way inferior to imported goods in terms of quality and precision. However, according to Mr. Ket, to be competitive, businesses need additional incentive mechanisms; prioritizing the use of domestic goods in economic projects and domestic investments.

"To revive the domestic mechanical engineering industry, the first thing we need is a market. But to create a market, the Government and relevant ministries and agencies need to have specific mechanisms for the industry. For example, prioritizing domestic products by limiting imports of products that can be manufactured domestically and well, and making them suitable for projects," Mr. Ket emphasized.

Source: https://congthuong.vn/doanh-nghiep-co-khi-day-manh-noi-dia-hoa-chiem-linh-thi-phan-360632.html

Comment (0)