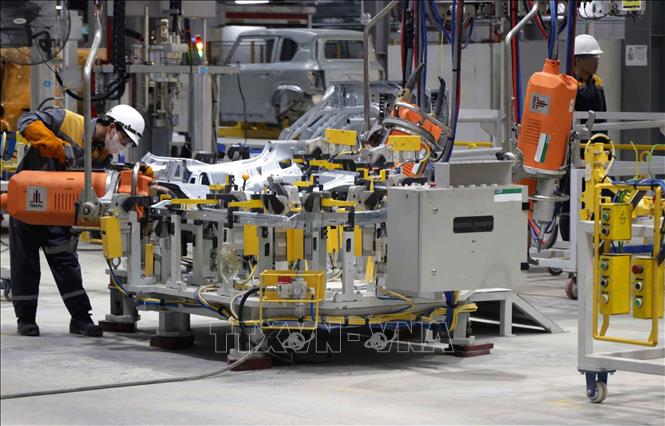

With a low rate of domestically produced components and weak supporting industries, while most of the added value still lies in imports, the Vietnamese automobile manufacturing industry is facing an urgent need to increase the localization rate - a vital factor to master the value chain, reduce trade deficit and affirm its position in the region.

Slow development of automobile localization

After more than a decade of implementing the Automotive Industry Development Strategy to 2025, Vietnam has recorded a number of achievements such as: Attracting investment, building production joint ventures, increasing output. However, according to experts, the localization rate of automobiles is still far from the set target.

Currently, Vietnam spends about 10 billion USD each year importing auto parts, increasing the trade deficit and keeping domestic added value at a low level. Some truck and bus models have a localization rate of 40-60%, but cars and passenger cars still depend heavily on imported parts. Meanwhile, domestic production capacity is only concentrated on some common parts such as tires, seats, batteries; while engines, gearboxes, and electronic systems are almost completely imported.

Prof. Dr. Hoang Van Cuong, Vice President of the National Economics University, commented: "The Vietnamese automobile market is divided among too many brands, leading to the output of each car line being too low, not creating motivation to invest in domestic component production. This is an important reason why the localization process has not met expectations."

In addition, preferential policies have not really encouraged businesses. The current tax schedule does not clearly differentiate according to component details, which invisibly facilitates the import of complete assemblies instead of developing domestic production.

Dr. Nguyen Van Hoi, Director of the Institute for Strategy and Policy Research on Industry and Trade, analyzed: "Vietnam's supporting industry is still weak. The metallurgy, electronics, and alloy materials industries are not developed enough to supply high-quality auto parts. Meanwhile, the commitment to localization and technology transfer from some FDI enterprises has not been implemented because the law lacks binding sanctions."

The above shortcomings show that, without a breakthrough policy, Vietnam's goal of localizing automobiles will remain at the expected level.

Breakthrough solution

To develop the Vietnamese automobile industry sustainably, many solutions have been proposed, focusing on perfecting policy mechanisms, enhancing the capacity of supporting industries and encouraging cooperation between domestic and foreign enterprises.

First of all, there needs to be a roadmap to bind localization for each vehicle line. Dr. Ngo Nhat Thai, an industrial economist, emphasized: "We cannot let businesses have full authority to decide whether to localize or not. The State needs to issue a specific roadmap, for example, by 2030, passenger cars must have at least 40% domestically produced components, thereby creating pressure to force businesses to invest."

At the same time, the import tax schedule for components needs to be developed in detail, with strong incentives for domestically produced products and increased taxes on imported components in complete sets. This approach both encourages domestic enterprises and limits the situation of "importing for assembly".

Another important solution is binding technology transfer. According to Prof. Dr. Hoang Van Cuong: "Investment contracts must include mandatory clauses on technology transfer. Foreign enterprises cannot enjoy incentives without contributing to the development of domestic capacity."

To support businesses, it is necessary to promote science and technology and human resource training. Building specialized automotive innovation centers and training high-quality engineers and technicians will help Vietnam quickly access new technology, especially in the context of the rising trend of electric and smart cars.

In addition to the domestic market, it is necessary to encourage enterprises to export components. When production scale is expanded and costs are reduced, Vietnamese products will have better competitiveness. At the same time, the State should regulate market share, limit market fragmentation, and encourage enterprises to cooperate in producing common components to achieve economies of scale.

Dr. Nguyen Van Hoi emphasized: "We must build a separate set of national technical standards for the automobile industry, aiming for green and smart standards. This is both a technical barrier to protect domestic production and a ticket to help Vietnamese components reach the world."

Auto localization is a key and strategic task, not only helping Vietnam reduce trade deficit but also creating momentum for supporting industry development, increasing employment and enhancing national status.

To achieve this goal, close coordination between the State and enterprises is needed. Policies must be strong enough, with clear sanctions, while domestic enterprises must proactively invest and improve their capacity to participate in the global supply chain.

The road to automobile localization still has many challenges, but with political determination and the support of the business community, this will be the key for Vietnamese industry to master the future.

Source: https://baotintuc.vn/kinh-te/noi-dia-hoa-o-to-yeu-to-song-con-de-lam-chu-cong-nghe-20251018081114150.htm

![[Photo] 60th Anniversary of the Founding of the Vietnam Association of Photographic Artists](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764935864512_a1-bnd-0841-9740-jpg.webp&w=3840&q=75)

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764951162416_2628509768338816493-6995-jpg.webp&w=3840&q=75)

Comment (0)