Technology as the “backbone” for stable growth

Visiting the Hai Duong Branch Factory (Animal Feed Factory) of CP Vietnam Livestock Joint Stock Company, the first impression is that the campus is 14 hectares wide but nearly 30% of the area is covered with trees, creating a production space in harmony with the environment.

The factory has a designed capacity of 720,000 tons/year, belonging to the group of largest animal feed factories of CP Vietnam in the North. The entire production line is equipped with synchronous grinding - mixing - pelleting - cooling - packaging stages, integrated with finished product sorting robots and automatic control systems. The products are developed according to specialized nutrition for each animal, without using growth hormones.

The campus of the Hai Duong Branch Factory (Animal Feed Factory) of CP Vietnam Livestock Joint Stock Company is 14 hectares wide, but nearly 30% of the area is covered with trees, creating a production space in harmony with the environment. Photo: HT .

During peak periods such as Tet, the factory can operate at 100% of its designed capacity; during normal times it remains stable at 80%, both optimizing production efficiency and flexibly responding to the market. It is expected that in the near future, the factory will continue to increase its capacity to 960,000 tons/year.

The Control Room monitors the entire production line in real time, helping to maintain a stable productivity of 800 - 850 tons/shift. The production system is automated in most stages, robots are responsible for loading and unloading finished products, helping to reduce manual labor, increase safety and operational efficiency.

The factory was invested in construction in 2011 and put into operation in 2014, with technology designed according to European standards. Photo: HT .

The factory also owns a Feed Technology laboratory with a sampling - coding - quality comparison system to ensure objectivity and stability for each product batch. Raw materials are received through a mechanized system, strictly controlled by the QC (quality management) department of CP Group, all storage conditions are monitored by a specialized system.

According to Mr. Vu Anh Tuan, Senior Deputy General Director of CP Vietnam, the main goal of the Factory Branch in Hai Duong is to effectively serve customers in the Northern region. "CP Vietnam's livestock industry generally maintains stability. This includes contributions from large-scale farms with stable purchasing demand and large volumes of goods. This is a positive signal, creating a foundation for the company's long-term development," Mr. Tuan shared.

Save energy, reduce emissions, and move towards sustainability

The factory was invested in construction in 2011 and put into operation in 2014, with technology designed according to European standards. Right from the design stage, CP Vietnam has oriented to build an environmentally friendly factory, achieving high efficiency in energy saving.

The company continuously invests in new technology, improves equipment and optimizes processes to reduce energy consumption and improve production efficiency. In formulating feed, the factory also optimizes input energy while ensuring quality.

Mr. Vu Anh Tuan, Senior Deputy General Director of CP Vietnam, said that right from the design stage, CP Vietnam has aimed to build an environmentally friendly factory that is highly efficient in energy saving. Photo: HT .

In its sustainable development strategy for the coming time, CP Vietnam prioritizes the use of biomass fuels such as sawdust and wood shavings to reduce emissions and utilize by-products. At the same time, the company focuses on solving the problem of plastic waste from food packaging: The weight of each bag has been reduced from 110g to about 87g, equivalent to cutting more than 20% of the amount of plastic used.

One strategic solution is to expand the delivery method by silo (feed tank). The Group's silo utilization rate increases by 5-7% per year, significantly reducing the amount of plastic packaging, applied to both internal livestock systems and external customers.

Enterprises continuously invest in new technology, improve equipment and optimize processes to reduce energy consumption and improve production efficiency. Photo: HT .

In the feed formula, CP Vietnam also adjusts towards balancing amino acids, limiting excess protein - the main cause of odor and emissions in the farm. This method not only increases nutritional efficiency but also significantly improves the livestock environment, in line with the sustainable development orientation of the enterprise.

Each ton of feed leaving the factory not only brings nutrition to livestock, but also conveys CP Vietnam's long-term commitment to the environment, the community and the future of sustainable agriculture .

Source: https://nongnghiepmoitruong.vn/cp-viet-namsan-xuat-thuc-an-chan-nuoi-hien-dai-huong-toi-phat-trien-ben-vung-d788174.html

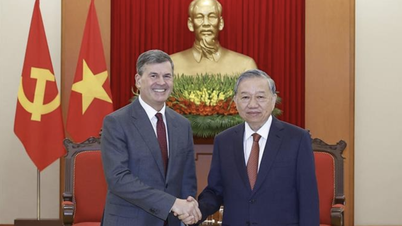

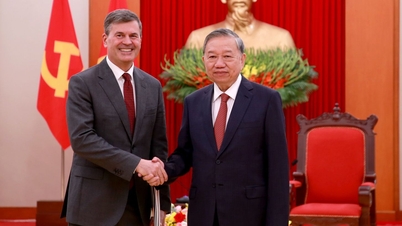

![[Photo] General Secretary To Lam receives the Director of the Academy of Public Administration and National Economy under the President of the Russian Federation](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F08%2F1765200203892_a1-bnd-0933-4198-jpg.webp&w=3840&q=75)

Comment (0)